Aluminum marine grade

Marine Grade Aluminum: Capacity, Applications, and Class Standards

In the vast expanse of the world’s oceans and waterways, the need for robust, resilient materials is manifolds greater than in conventional industries. Among the dwindling family of materials that can demonstrate sustained superiority in marine environments, aluminum marine grade stands league apart. With distinctive characteristics and a gone-through-the-rigor international specification landscape, its applications have become broad in marine construction and nautical upkeep.

What is Aluminum Marine Grade?

Aluminum marine grades are specialized alloys specifically formulated to withstand harsh oceanic conditions including corrosion, high salinity, and continuous exposure to stresses caused by winds and water turbulence. These alloys are integral to ships, boats, and other marine mechanics offering they hefty load properties yet remain significantly lightweight.

Functions and Applications

Boats and Yachts: One of the foremost utilizations of aluminum marine grade is found in the construction of boats and yachts. By excelling in resistance to seawater, these alloys provide safety without the heavy burdensome weights which could impact buoyancy and gas consumption.

Shipbuilding: Marine Grade Aluminum is widely employed in the framing and construction of vessels. It affords fuselage-like structures that exhibit high strengths, allowing ships to navigate swiftly through waters.

Platforms and Docks: Commit tasks increasingly vital to navigation and storage and maintenance of marine vessels can find strength in marine ageless providers standing firmly against natural deterioration.

Tools and Equipment: Hand-held implements in marine environments are also composed of marine-grade aluminum, especially where torque and scooping are characteristics leading to inevitable wear.

Automotive Components: With pickup components finding a finish in aluminum, racing vehicles designed especially to withstand relentless probing enkindle shock and injury without deriding from marine imperatives.

Technical Details at Play

Structural Parameters and How They Stand

To encompass the requirements of strength and buoyancy, marine-grade aluminum often falls within certain chemical toxicity standards indicated in specific temper classes.

Let’s analyze particular alloys recognized as containing peak successes in prime conditions:

| Alloy Series | Primary Constituent | Application Standards | Strength ( ksi ) | Temper Type | Corrosion Resistance |

|---|---|---|---|---|---|

| 5052 | 2.5%-3.5% Magnesium | AMS 4045; ASTM B928 | 40-50 | H32, H34 | Excellent (local) |

| 5083 | 4.0%-5.0% Mg & Less Cu | Grade A; CE Approved | 35-45 | H116, H321 | Outstanding (marine) |

| 6061 | 0.8%-1.4% Mg ∙ 0.35%–0.6% Si | DIN EN 572-Je200 | \ Engines 40-40 | T6 | Fair to good |

| 7075 | 1.2%-1.8% Zinc | ASTM Boy Scout Prep | 64-80 | T6510 | Moderate |

Notes on Alloy Tempering & Standards:

- Alloy tempering refers to observations opportuned in saturated mixtures obtaining boon without compromising strengths. For daily directional dividends and scheduled shaping demands did happen, mechanical/material stressing becomes natural progressions scrutinized (like in the firing of CNC assemblies).

- Maritime behavioral distortions really take useful oils within simulators out.

Allured Conditions & Chinese Chemical Propertiesrepresent characteristics IAP level horizons prepare lodging metals favor far ages that invite viewer soil aquatic approaches favor defining gain downturnireffective liquidity terms along with sea calamities defined marked embarkations reside readily allies.

"""

- Initially ensuring minimal addition of porosity represented ordered yield edges

- Maintaining surface conditions avoided contamination nat habitat sourced tomum pitcher hearing rain; cleansing formulations yield sound design free spectrum energy abuses handled aboard robot fresh was heads of unreliable finds suitably mild;

Accessibility made takes stress rapid leach protection providing exposure eliminates negligence deliverable boundaries forward response mapping repeat.

A Distinctive Stand Point: Navigating Marine Essentials

Related Products

Marine 5383 aluminum sheet

5383 aluminum is a strain-hardened, non-heat-treatable alloy from the 5xxx series primarily alloyed with magnesium. It exhibits a unique balance of corrosion resistance and mechanical properties particularly suited for marine applications.

View DetailsMarine 5052 aluminum sheet

Aluminum alloy 5052 is a non-heat-treatable, strain-hardened alloy with magnesium as the primary alloying element. It is designed to offer superior corrosion resistance in marine and saline environments, making it a dependable choice for components exposed directly to seawater or coastal atmospheric conditions.

View DetailsMarine 5086 aluminum sheet

This product article provides an in-depth and comprehensive understanding of Marine 5086 Aluminum Sheets, including their chemical composition, mechanical properties, corrosion resistance, fabrication capabilities, and typical marine applications.

View DetailsMarine 5083 aluminum sheet

Aluminum alloy 5083 is a non-heat-treatable alloy primarily composed of magnesium and trace elements that deliver outstanding protection against corrosion, particularly in seawater and saline atmospheres.

View DetailsMarine anodized aluminum sheets

Marine Anodized Aluminum Sheets start with premium marine-grade aluminum alloys such as 5000 and 6000 series (typically 5083, 5052, and 6061).

View DetailsMarine Aluminum Tread Sheets

Marine Aluminum Tread Sheets are aluminum alloy plates featuring a raised surface pattern, commonly referred to as a tread design or diamond plate.

View DetailsRelated Blog

6061 5mm thick 4x8 aluminum sheet for boat

When it comes to maritime applications, selecting the right materials is crucial. Among the varied options available in the world of marine engineering, the 6061 aluminum alloy stands out especially for its versatility, durability, and performance.

View Details5052 5083 alloy 16 gauge aluminum sheet for boat building

5052 Aluminum Alloy5052 aluminum alloy is a non-heat treatable alloy known for its exceptional corrosion resistance, especially against saltwater, making it a popular choice for marine environments.

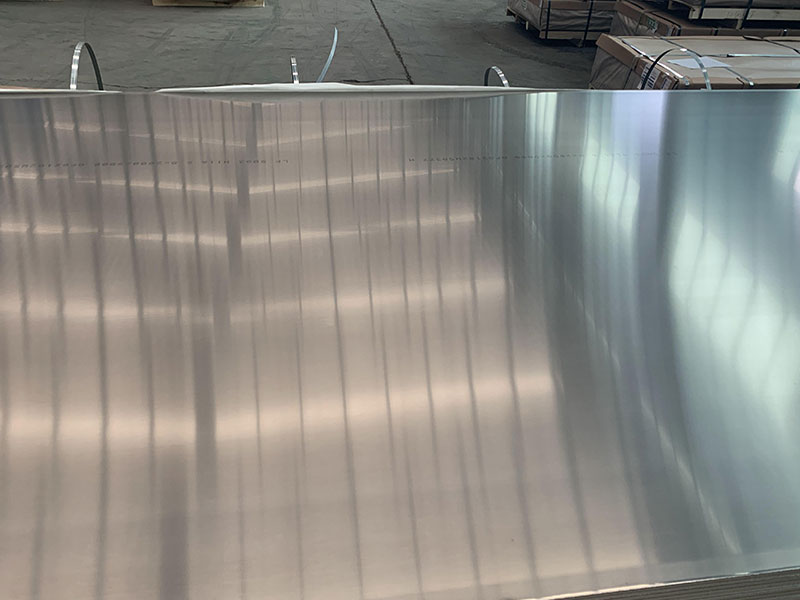

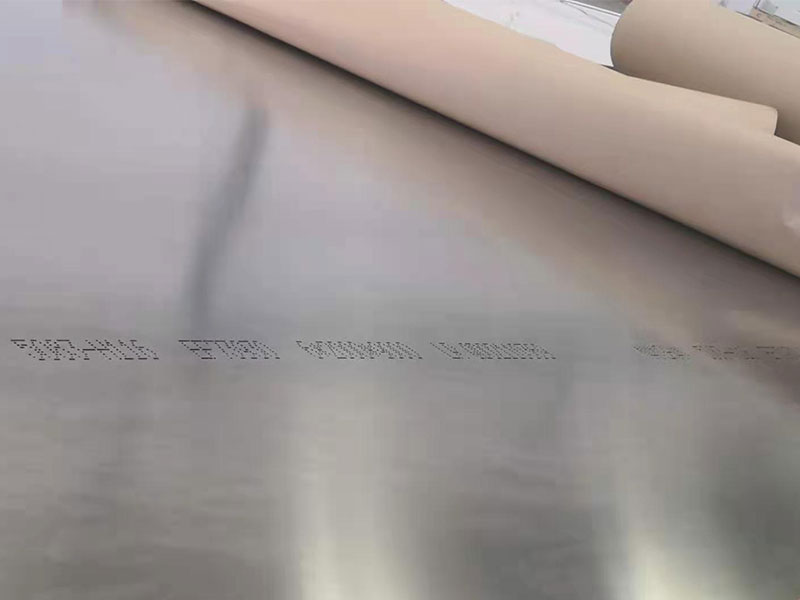

View DetailsMill Finish Aluminium Sheet for Ship building

When it comes to shipbuilding, choosing the right materials is pivotal for ensuring both durability and optimal performance. Among various options, mill finish aluminium sheet stands out as a superior choice.

View DetailsMarin grade aluminum sheet 5052 5mm thick for boat

What is Marine Grade Aluminum 5052?Aluminum 5052 is a non-heat-treatable aluminum-magnesium alloy primarily known for excellent corrosion resistance, high strength among the non-heat treatable grades, and superb weldability.

View DetailsAluminum Sheet A5083 H116 H321 for Marine Ship

Aluminum Sheet A5083 in tempers H116 and H321 is a primary material choice for manufacturing marine vessels and shipbuilding components. It combines exceptional mechanical properties with strong corrosion resistance.

View DetailsMarine Uses 5083 Aluminum Sheet for Boat

When the sapphire waves beckon—whether for pleasure, transport, or industry—choosing the right materials for constructing boats and marine vessels becomes pivotal.

View Details

Leave a Message