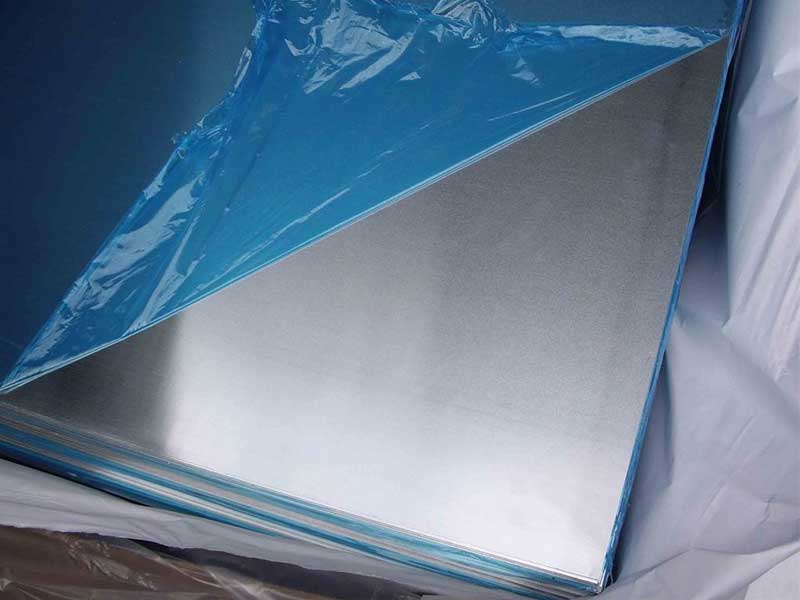

Marine aluminum plate 5005 5052 color coated

In the marine industry, where reliability meets aesthetics, Aluminum Plate 5005 and 5052 color coated options have taken the forefront as building materials. With undeniably strength, corrosion resistance, and a visually appealing surface, these alloys are game-changers in marine applications. This comprehensive guide explores the technical parameters, implementation standards, alloy tempering processes, and chemical properties in order to establish why choosing colored marine aluminum plates can provide unique advantages.

The Technical Edge of Marine Aluminum Plates

Alloys: 5005 vs 5052

While both 5005 and 5052 Aluminum Plates hold exceptional properties suited for marine environments, choosing the right grade depends on the intended application:

Aluminum 5005: Known for its decorative qualities, it's perfect for applications requiring aesthetic adherence without compromising strength. With a medium strength level, Aluminum 5005 finds its use in decorative panels and accents while resisting corrosion effectively. Its formability exceeds conventional standards, and it's considered a smart choice for architectural and beautification needs.

Adhesive Spectrum of 5052: On the other hand, Aluminum 5052 shines in high-strength need scenarios; it boasts better workability with excellent fatigue and weld reparability, and overall durability. As a fleet hull material or infrastructural support, alloys in the 5052 range demonstrate an unwavering response to intensive marine applications thanks to their inherently elevated resistance to maritime corrosion.

Implementation Standards

Quality operations align with rigorous industry standards. Both summarized alloys are backed by various certifications ensuring performance excellence across applications. The following particular standards are deemed suitable in many contexts:

ASTM B209: This sets expectations for thickness, mechanical, and physical properties for the production of aluminum sheet and plate, indicating the minimum specification accepting toughness under different climatic and servicing angles.

Marine Connections: MIL-STD: For military marine applications, adherence to the recognized MIL standards is obligatory, guaranteeing top-tier performance even under adverse marine experiences.

Delving into Alloy Tempering and Processing Conditions

The changes made during the manufacturing process uncover essential features of Aluminum 5005 and 5052. Standard temper designations—HXXX showcasing the tempering state post-significant mechanical treatment—play vital facets in discerning material performance:

5005: H32 Hot Rolled – It represents work-hardened marked from gradual hot rolling condition solidifying strength while remaining highly malleable. Surface treatments bring out fantastic coloring possibilities offering creative construction avenues.

5052: H34 Cold Rolled – Being about 5¼% more robust euphemizes enhanced corrosion resistance. Drawn in standard structural frames traditionally employed in ships can penetrate each quadrant amidst salty water galaxy philosophy jointly shaping desired attributes.

Chemical Properties Table

the unique chemical makeup of Aluminum 5005 and 5052 helps evaluate their performance in seasoned marine environments. Reference cherished tables ensuring proper correlations enthrui systemic contemplations.

| Component | 5005 | 5052 |

|---|---|---|

| Aluminum (Al) | 95.7% - 98.7% | 97.25% - 99.3% |

| Manganese (Mn) | 0.5% - 1.0% | 0.10% - 0.5% |

| Magnesium (Mg) | 0.5% - 1.0% | 2.2% - 2.8% |

| Silicon (Si) | 0.60% max | 0.25% max |

| Copper (Cu) | 0.40% max | 0.10% max |

| Iron (Fe) | 0.50% max | 0.40% max |

| Zinc (Zn) | 0.10% max | 0.25% max |

The Color-Coating Advantage

Beyond opting for specific alloy parameters, the color-coating provides an additional layer of customization benefitting aesthetics, solar reflectivity, and potential tidal leverage against biofouling. Manufacturers leveraging this aesthetic appeal incorporates substrate equipment maximizing adaptability in varied marine designs— subsequently meeting visual integrity forms while decorating various structures ranging from the finest intricacies down to hull beneath operations.

Related Products

Marine 5086 aluminum plate

5086 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys. Its hallmark is a high magnesium content—generally between 4.0% and 4.9%—which delivers enhanced corrosion resistance, particularly against saltwater and marine atmospheric conditions.

View DetailsMarine 5383 aluminum plate

The 5383 aluminum alloy belongs to the 5xxx series of aluminum-magnesium alloys known for remarkable resistance to marine corrosion and high strength.

View DetailsMarine 5059 aluminum plate

Marine 5059 Aluminum Plate is distinguished by its high magnesium content and carefully balanced alloying elements, designed to maximize strength without compromising corrosion resistance.

View DetailsMarine 5052 aluminum plate

Marine 5052 Aluminum Plate is noted for its exceptional resistance to corrosion caused by seawater, salt spray, and marine atmospheres.

View DetailsMarine 5083 aluminum plate

Marine 5083 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys and is classified as a non-heat-treatable alloy. Its high magnesium content (typically 4.0–4.9%) enhances its corrosion resistance, especially against seawater-related degradation such as pitting and stress corrosion cracking.

View DetailsMarine aluminum steel clad plate

Aluminum / Steel Clad Plates consist of a sandwich construction in which a layer of marine-grade aluminum alloy is metallurgically bonded to a steel substrate.

View DetailsRelated Blog

Marine aluminum plate 5005 5052 color coated

In the marine industry, where reliability meets aesthetics, Aluminum Plate 5005 and 5052 color coated options have taken the forefront as building materials. With undeniably strength, corrosion resistance, and a visually appealing surface.

View Details

Leave a Message