Marine Aluminum Rod & Bar for Boat Deck Reinforcements

In the demanding marine environment, materials must withstand harsh conditions including saltwater exposure, mechanical stresses, and varying weather. Marine-grade aluminum rods and bars have become the material of choice for boat deck reinforcements due to their superior strength, corrosion resistance, and lightweight properties.

Marine aluminum rods and bars are precision-manufactured aluminum alloys designed specially for use in marine applications such as boat deck reinforcements, structural framing, and hull modifications. These materials offer an excellent strength-to-weight ratio, superior resistance to corrosion caused by saltwater, and ease of fabrication.

Features

1. Corrosion Resistance

Marine-grade aluminum alloys, primarily series 5xxx (Al-Mg alloys), contain magnesium as the principal alloying element, providing high resistance to corrosion from seawater and marine atmospheres. This makes them far more durable and longer-lasting compared to steel or lesser aluminum alloys in maritime environments.

2. High Strength and Durability

Despite their light weight, marine aluminum rods and bars deliver tensile and yield strength, ensuring structural integrity and excellent performance. This enables them to reinforce boat decks, which are subject to heavy loads and dynamic stresses onboard seagoing vessels.

3. Lightweight

Compared to steel or stainless steel, aluminum weighs approximately one-third as much. Using aluminum rods and bars for deck reinforcements helps reduce overall boat weight, improving fuel efficiency, stability, and speed.

4. Excellent Fabrication Characteristics

Marine aluminum is notable for its ease of fabrication including cutting, machining, welding, and bending. This advantage allows for customized reinforcements, retrofitting, or manufacturing of complex deck structures that fit exact engineering requirements.

5. Low Maintenance

Thanks to its resistance to rust and corrosion, aluminum marine bars and rods require minimal maintenance, eliminating frequent repainting or repairs, thus lowering lifecycle costs.

Chemical Composition of Typical Marine Aluminum Alloy (e.g., ASTM B221 Series 5000, 5083/5052)

| Element | Typical Weight % |

|---|---|

| Aluminum (Al) | Balance (94.4 - 97.9) |

| Magnesium (Mg) | 3.0 – 5.0 |

| Manganese (Mn) | 0.3 – 0.7 |

| Chromium (Cr) | 0.05 – 0.25 |

| Iron (Fe) | ≤ 0.4 |

| Silicon (Si) | ≤ 0.4 |

| Copper (Cu) | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.25 |

| Others | ≤ 0.15 |

Mechanical Properties of Common Marine Aluminum Alloys

| Alloy | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Density (g/cm³) |

|---|---|---|---|---|

| 5052 | 193 | 228 | 12 | 2.68 |

| 5083 | 215-275 | 317-355 | 12-16 | 2.66 |

Available Sizes

Marine aluminum rods and bars can be supplied in various standardized diameters and thicknesses to meet diverse reinforcement demands. Common options include:

| Form | Size Range (mm) |

|---|---|

| Rod | 6mm — 150mm diameter |

| Square Bar | 10mm x 10mm to 150mm x 150mm |

| Flat Bar | Thickness from 4mm to 30mm ; Width from 20mm to 300mm |

| Round Bar | 6mm to 150mm diameter |

Custom sizes and lengths can also be quoted to facilitate specific engineering designs.

Applications in Boat Deck Reinforcements

1. Structural Reinforcement Beams

Aluminum bars are used as reinforcing frames beneath the deck surfaces, supporting decking materials and distributing loads effectively. This avoids deck deformation and prolongs vessel life.

2. Brackets, Mounting Fixtures & Hardware

Aluminum rods offer strong, corrosion-resistant resources for building mounting brackets, stanchions, and deck hardware that need to withstand marine vibrations and stresses.

3. Ladder Rails and Guardrails

Durable aluminum bars are the preferred choice for progressively engineered railings around decks to enhance passenger safety.

4. Repair & Retrofit Projects

Marine-grade aluminum rods enable efficient reinforcement or replacement of weakened support structures in aging boats without significantly increasing weight.

Marine aluminum rods and bars are essential materials for ensuring the longevity, strength, and functionality of boat deck reinforcements. Their superior corrosion resistance, outstanding mechanical properties, and fabrication flexibility fulfill state-of-the-art demands of marine architecture. When selecting materials for your marine reinforcement project, choose certified marine aluminum alloys like 5083 and 5052 to guarantee compliance with marine standards and top-grade performance.

Buy with Confidence

Our marine aluminum rods and bars comply with international standards such as ASTM B221 and are tested for chemical composition and mechanical strengths by certified labs. Partner with us to obtain premium marine-grade aluminum that boosts durability, reduces maintenance, and enhances the safety of your boat decks.

For inquiries on specific sizes, certifications, or custom orders, please contact our technical support team.

Invest in quality marine aluminum rods & bars and safeguard your maritime investments with trusted innovations.

Related Products

5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View Details6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

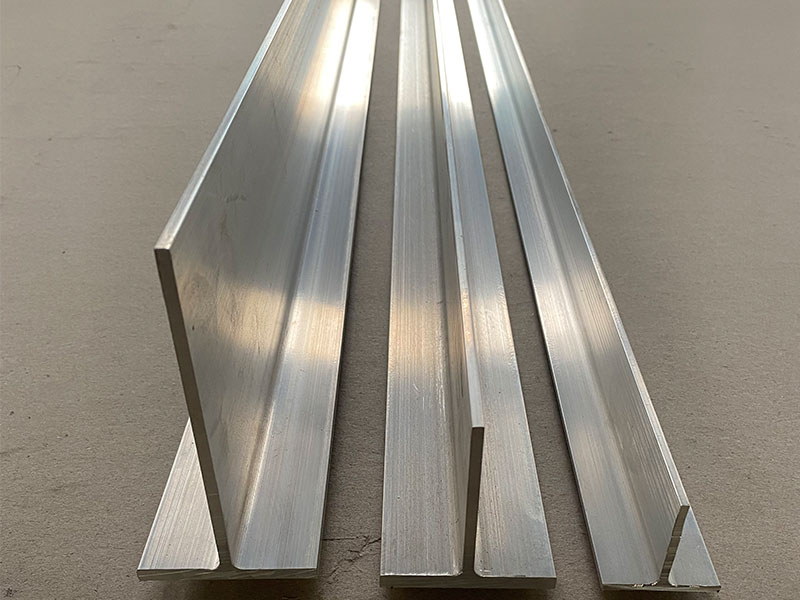

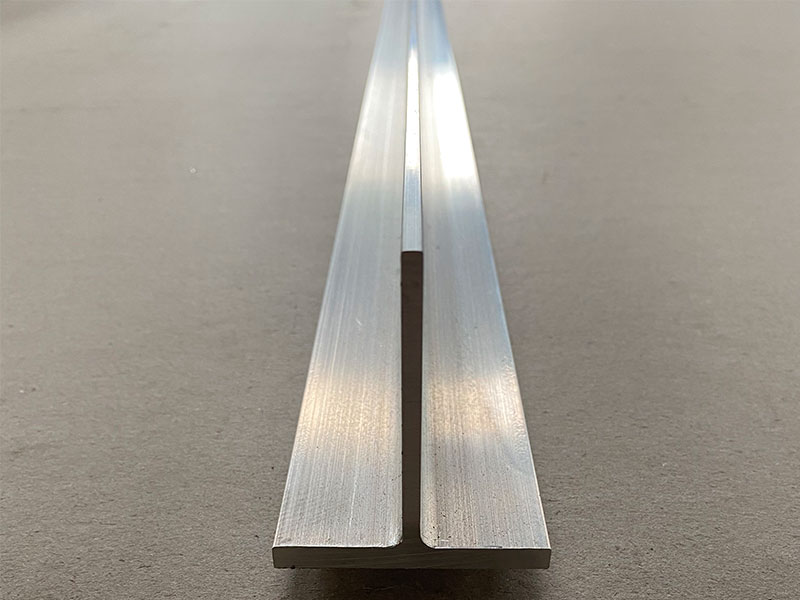

View DetailsMarine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View DetailsMarine aluminum I-beams

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction.

View DetailsMarine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View DetailsMarine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View DetailsRelated Blog

6061 Marine Aluminum Rod & Bar for Durable Boat Deck Design

When it comes to crafting a boat deck that not only withstands the rigorous marine environment but also elevates performance and longevity, the choice of material is paramount.

View Details5083 Marine Aluminum I Beams for High Strength Coastal Engineering

5083 aluminum alloy belongs to the non-heat-treatable Al-Mg-Mn family. Known primarily for excellent corrosion resistance, welding ability, and strong mechanical properties without added heat treatment.

View DetailsMarine Aluminum Flat Bar for Offshore Boat and Platform Reinforcement

High-performance marine aluminum flat bars engineered for offshore boat and platform reinforcement applications. Steel-like strength, corrosion resistance, and optimal composition for harsh marine environments.

View DetailsMarine Aluminum Flat Bar for Offshore Platform Fabrication

Marine Aluminum Flat Bar for Offshore Platform Fabrication: A Comprehensive Guide to Functions, Applications, and Technical InsightsIn the demanding environment of offshore platform fabrication, material selection is paramount to ensure durability.

View Details6061 Marine Aluminum Angles for Boat Deck Support and Reinforcement

6061 Marine Aluminum Angles are specially designed aluminum alloy structural components, widely used in marine environments for boat deck support, reinforcement, and framework.

View Details5083 Marine Aluminum Round Bar for High Strength Offshore Reinforcements

In the demanding world of offshore engineering, materials must withstand severe environmental conditions without compromising structural integrity. One such pivotal material is the 5083 Marine Aluminum Round Bar.

View Details

Leave a Message