Marine Aluminum Z Shaped Sections for Seawater Proof Engineering Solutions

Marine Aluminum Z Shaped Sections for Seawater Proof Engineering Solutions

When it comes to engineering structures that are exposed to constant seawater contact, material selection and design profiles become paramount. Among specialized materials, Marine Aluminum has emerged as a preferred choice due to its inherent corrosion resistance, outstanding strength-to-weight ratio, and alloy versatility. One distinctive format gaining considerable traction in maritime applications is the Marine Aluminum Z Shaped Section. This profile combines structural efficiency with seawater resilience, empowering engineers to elevate seaworthy infrastructure to new standards of durability and functionality.

Z Shaped Sections in Marine Aluminum

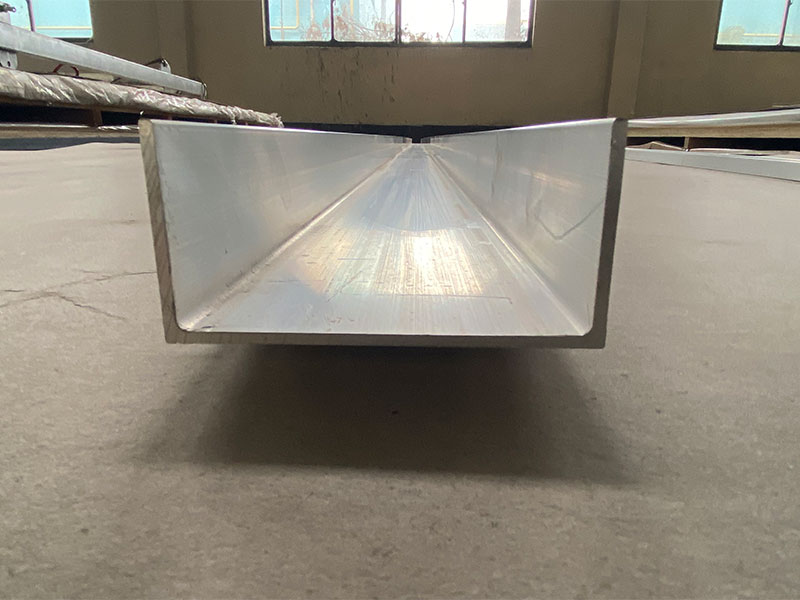

The "Z" shaped aluminum profile gets its name from its cross-sectional shape resembling the letter "Z." Unlike flat plates or standard angles, the Z section enhances stability against twisting and bending moments. Its geometry inherently increases flexural rigidity per unit weight, which is invaluable in marine settings where components often face dynamic wave forces, wind loads, and saltwater induced wear.

Technical Features:

- Shape Geometry: The offset flanges combined with a central web offers high bending resistance and good performance under torsional loads.

- Material Composition: Typically made from high-grade 5xxx or 6xxx series aluminum alloys, these sections leverage exceptional seawater corrosion resistance without requiring bulky protective coatings.

- Dimensions & Weight: Available in customized thicknesses ranging between 3mm to 10mm or more, Z sections are lightweight and facilitate efficient transport and assembly onboard or onshore.

- Surface Finishes: Anodizing or powder coating options provide aesthetical qualities plus a secondary defense against aggressive marine environments.

Functions and Benefits in Marine Engineering

1. Structural Envelope Components

In marine vessels, offshore platforms, docks, and floating structures, Z sections function as primary load-bearing members or reinforcements, ensuring structural integrity under multidirectional stresses. Their optimized configuration spreads loads evenly which minimizes points of stress concentration prone to cracking.

2. Seawater Proof Coatings and Attachments

Due to the combination of high mechanical strength and corrosion resistance, these profiles are the backbone for platforms that install pipelines, seawater cooling units, and specialized equipment shoes that interface directly with seawater and humid atmospheres.

3. Modular Construction Systems

Marine Aluminum Z sections facilitate efficient modular design and fabrication. Their ease of welding and bending enables bespoke configurations such as framing systems, railings, and weatherproof cladding. Modular designs reduce onsite construction time, cost, and human exposure to hazardous wave conditions.

Applications in Diverse Seawater Proof Projects

- Marine Vessels: Cut through weight restrictions by employing Z sections in bulkheads and superstructures—ideal for fuel efficiency and payload optimization.

- Offshore Platforms & Oil Rigs: Reinforce platforms against corrosive spray zones and lightweight structural demands.

- Seawater Intake and Cooling Systems: Form wear-resistant brackets, trough conveyors, and sluice gates where persistent saline corrosion can deteriorate weaker metals.

- Harbor and Pier Construction: Used as lintels, breakwater edge supports, and seawall retention stiffeners with overhaul-free service longevity.

- Aquaculture Installations: Cage supports and submerged framework in saltwater farms maintain hygiene compliance and prevent premature metal fatigue.

Technical Insight: Corrosion Resistance Mechanisms

Marine Aluminum alloys used in Z shaped sections typically contain magnesium or silicon additives, which form a self-healing oxide layer when exposed to molten salt or moisture. This aluminum oxide film acts as an invisible shield preventing ion penetration and subsequent electrochemical reactions prevalent in marine corrosion cycles. Notably, the extruded Z shape can be engineered with precision to guide drainage, avoid water pooling, and minimize crevices—often hotspots for localized corrosion.

Related Products

6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

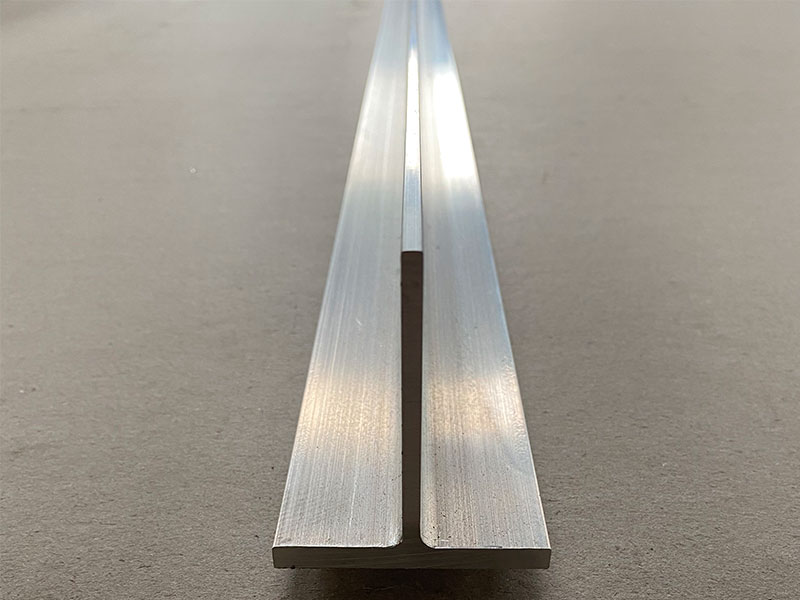

View DetailsMarine aluminum I-beams

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction.

View DetailsMarine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View DetailsMarine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View DetailsMarine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View DetailsRelated Blog

Marine Aluminum Rod & Bar for High Performance Boat Construction

In the demanding field of high performance boat construction, material selection is critical to achieving the perfect balance of strength, weight, corrosion resistance, and durability.

View Details5083 Marine Aluminum I Beams for Seawater Resistant Boat Hull Design

Constructing seawater resistant boat hulls demands not only impeccable design but also the right choice of materials engineered for marine environments. Among available metals.

View DetailsMarine Aluminum Round Bar for Saltwater Resistant Boat Design

When designing boats destined for saltwater environments, materials selection is paramount for ensuring long-lasting performance and reliable structural integrity.

View DetailsMarine Aluminum Flat Bar for Offshore Platform Fabrication

Marine Aluminum Flat Bar for Offshore Platform Fabrication: A Comprehensive Guide to Functions, Applications, and Technical InsightsIn the demanding environment of offshore platform fabrication, material selection is paramount to ensure durability.

View Details5083 Marine Aluminum Angles for Heavy Duty Offshore Boat Hulls

In the demanding world of offshore marine engineering, selecting the right materials for constructing boat hulls is critical.

View Details5083 Marine Aluminum Channels for Lightweight Marine Vessel Design

5083 Marine Aluminum Channels for Lightweight Marine Vessel Design: A Perfect Fusion of Strength, Durability, and Corrosion ResistanceIn the evolving world of marine vessel design, the quest for materials that offer unbeatable strength.

View Details

Leave a Message