Marine Aluminum Round Bar for Custom Marine Vessel Construction

Marine Aluminum Round Bars are crucial in the custom manufacturing of marine vessels where strength, weight, and corrosion resistance must be optimally balanced. As a senior engineer, I will guide you through the defining features, implementation standards, characteristics, and common alloy and temper options for Marine Aluminum Round Bars designed specifically for stringent maritime applications.

Marine Aluminum Round Bars serve as vital components in hull reinforcements, structural supports, shafts, and other critical mechanical parts of marine vessels—from boats and yachts to commercial ships. Their corrosion resistance and outstanding strength-to-weight ratios make them indispensable for ensuring long-lasting vessel performance even in the corrosive saltwater environment.

Materials and Alloy Composition

The heart of your marine aluminum product is the alloy selected, which must conform to marine-grade standards. Most marine aluminum round bars use the 5xxx series aluminum alloys. The most common alloy is 5083, notable for its excellent corrosion resistance, especially against seawater and pollutants.

Aluminum Alloy Options for Marine Round Bars:

|-------|--------------------------------------------------------|-----------------------------------------------------------------------------|| 5083 | Al Bal; Mg 4.0-4.9; Mn 0.4-1.0; Cr 0.05-0.25 | Exceptional corrosion resistance, high strength, good weldability || 5086 | Al Bal; Mg 4.5-5.2; Mn 0.2-0.7 | Excellent corrosion resistance and formability—suitable for marine applications || 5005 | Al Bal; Mg 0.5-1.1 | Moderate strength, excellent corrosion resistance but less common in load-bearing bars |

Temper Conditions

The temper of aluminum determines its strength, hardness, and ductility. Utilizing proper tempers is essential for functionality and manufacturability.

| Temper | Description | Typical Application |

|---|---|---|

| O | Annealed (Soft) | Forming and machining stages |

| H111 | Strain Hardened - Slightly | Light-duty marine applications |

| H112 | Strain Hardened - for extrusions | Suitable for general extruded products |

| H116 | Strain Hardened + solution heat-treated | Marine-grade applications for seawater exposure, offering superior corrosion resistance |

| H321 | Strain hardened + stabilized | Resistance to intergranular corrosion |

Mechanical Properties (Typical of 5083-H116 Round Bars)

| Property | Unit | Value |

|---|---|---|

| Tensile Strength | MPa | 275 - 350 |

| Yield Strength | MPa | 145 - 215 |

| Elongation (min) | % | 12 - 18 |

| Density | g/cm³ | 2.66 |

| Modulus of Elasticity | GPa | 70 |

Corrosion Resistance and Standality

- Marine aluminum bars manufactured with alloy 5xxx series exhibit excellent corrosion resistance, critical to marine vessel longevity.

- The H116 temper is often chosen for direct seawater exposure—enhancing resistance to stress corrosion cracking.

- Surface treatments and anodizing are often performed to increase oxidation resistance and aesthetic appeal.

Industry Standards and Implementation Guidelines

Our marine aluminum round bars comply with global standards ensuring uniformity, structural reliability, and safety.

| Standard | Relevance |

|---|---|

| ASTM B247 | Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes |

| MIL-DTL-24779 / QQ-A-250/11 | U.S. Military specification for Aluminum Bars 5083 Qualification |

| ISO 6361 | International standard for wrought aluminum and aluminum alloys |

| 3.1 / 3.2 Inspection | Mechanical testing certification and chemical composition certification |

Dimensional Availability and Customization

- Diameter Range: 6 mm to 250 mm (custom cut capabilities)

- Length: Typically supplied in 6m lengths; customized cut-to-length options available

- Surface Finish: Straightened, polished, or with factory machining options for custom parts

Manufacturing Process and Testing

- Extrusion and Hot Rolling: Ensure homogenous grain structure for superior strength and corrosion resistance.

- Heat Treatment: Creates the required temper via solution annealing and controlled cooling.

- Non-destructive Testing (NDT): Includes ultrasonic defect detection to ensure purity.

- Hardness Testing: Validates the mechanical properties per temper requirements.

Applications in Marine Vessel Construction

Marine aluminum round bars are often used in:

- Structural frames and reinforcements for yachts and ferries

- Propeller shafts and machinery components susceptible to stress loading

- Fittings exposed to saltwater and marine atmosphere requiring excellent corrosion resistance

- Custom-manufactured cleats, rails, and deck equipment

Related Products

6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

View Details6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

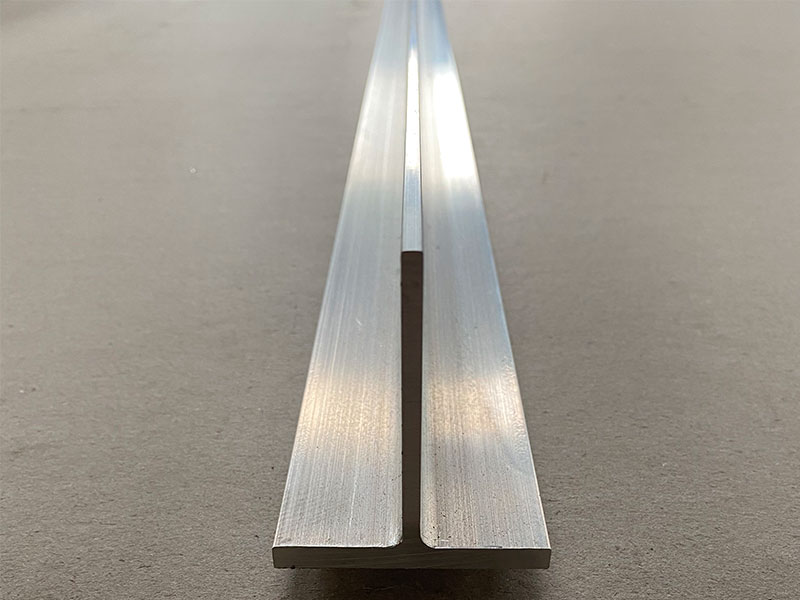

View DetailsMarine aluminum I-beams

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction.

View DetailsMarine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

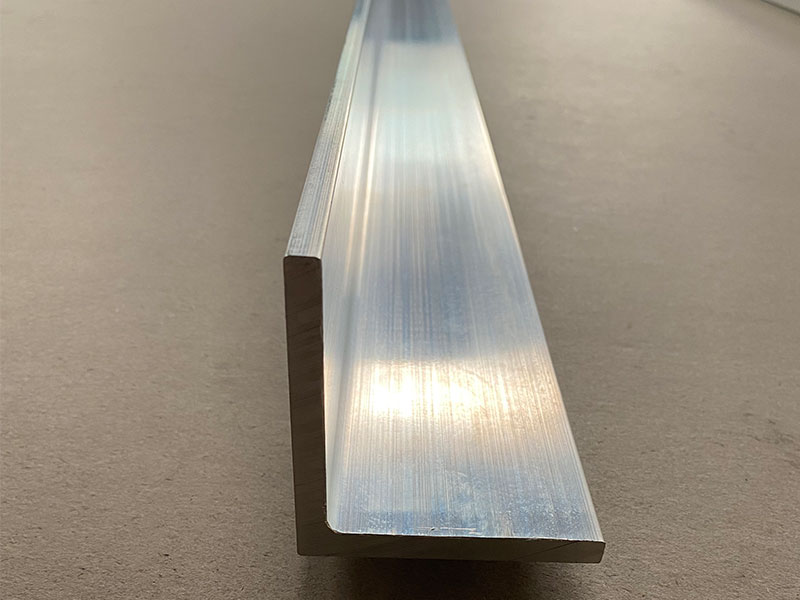

View DetailsMarine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View DetailsRelated Blog

Marine Aluminum Flat Bar for Durable Boat Hull Fabrication

When it comes to building boats that brave the unpredictable, often harsh marine environment, the choice of materials determines their longevity, safety, and performance.

View DetailsMarine Aluminum Flat Bar for Offshore Platform Fabrication

Marine Aluminum Flat Bar for Offshore Platform Fabrication: A Comprehensive Guide to Functions, Applications, and Technical InsightsIn the demanding environment of offshore platform fabrication, material selection is paramount to ensure durability.

View Details5083 Marine Aluminum Round Bar for High Strength Offshore Reinforcements

In the demanding world of offshore engineering, materials must withstand severe environmental conditions without compromising structural integrity. One such pivotal material is the 5083 Marine Aluminum Round Bar.

View Details5052 Marine Aluminum Channels for Custom Boat Hull Construction

Aluminum channels are indispensable components in marine construction, providing structural support, corrosion resistance, and design versatility. Among various aluminum alloys available.

View DetailsMarine Aluminum Rod & Bar for Boat Deck Reinforcements

In the demanding marine environment, materials must withstand harsh conditions including saltwater exposure, mechanical stresses, and varying weather.

View Details6061 Marine Aluminum Channels for Custom Marine Component Fabrication

When it comes to constructing reliable, corrosion-resistant, and durable marine structures, the choice of material is pivotal. Among several options.

View Details

Leave a Message