Marine Aluminum Channels for Heavy Duty Boat Frame Design

Designing a strong, lightweight, and corrosion‑resistant frame is at the heart of every reliable marine vessel. Marine aluminum channels bring all three advantages together, making them a preferred choice for boat builders, shipyards, and custom fabricators.

Marine aluminum channels are extruded profiles with a “C” or “U” cross‑section, engineered to withstand high static and dynamic loads in harsh saltwater environments. They are commonly produced from marine‑grade aluminum alloys such as 5052, 5083, 5086, 5456, and 6061 (for non‑immersed or lightly loaded components).

Typical marine channel profiles include:

| Profile Type | Description | Typical Use Area |

|---|---|---|

| Standard C‑Channel | Symmetrical C shape, equal flanges | Longitudinal frame members, stringers |

| Tapered Channel | Web or flange tapers along length | Weight‑optimized framing |

| Reinforced Channel | Thicker web or added ribs | High‑load connection zones, deck beams |

| Custom Channel | Customer‑specific geometry and radii | OEM systems, high‑end custom yachts |

Features for Heavy Duty Boat Frames

Corrosion Resistance in Saltwater

Marine channels made from 5xxx‑series alloys offer excellent resistance to pitting and stress corrosion cracking in seawater environments. Proper alloy choice and surface preparation can significantly extend service life.

| Alloy Grade | Corrosion Resistance in Seawater | Typical Use in Marine Frames |

|---|---|---|

| 5052 | Good | Light frameworks, interior structures |

| 5083 | Excellent | Hull framing, bottom stiffeners |

| 5086 | Excellent | High‑strength frames, patrol and workboats |

| 5456 | Very high | Heavily loaded structural zones |

| 6061 | Moderate (when anodized/painted) | Superstructures, masts, non‑immersed frames |

High Strength‑to‑Weight Ratio

Compared with steel, aluminum channels can deliver similar stiffness at a fraction of the mass, which means:

- Faster acceleration and higher fuel efficiency

- Reduced draft and improved payload capacity

- Easier manual handling and assembly

Representative mechanical properties for common marine channel alloys (typical values, temper‑dependent):

| Property | 5083‑H116 | 5086‑H116 | 6061‑T6 |

|---|---|---|---|

| Density (g/cm³) | 2.66 | 2.65 | 2.70 |

| Tensile Strength (MPa) | 275–350 | 260–345 | 290–350 |

| Yield Strength 0.2% (MPa) | 125–240 | 125–240 | 240–300 |

| Elongation (%) | 10–16 | 10–16 | 8–12 |

| Modulus of Elasticity (GPa) | ~70 | ~69 | ~69 |

Weldability and Fabrication

Marine aluminum channels are designed for efficient fabrication:

| Fabrication Aspect | 5xxx Series (5052, 5083, 5086) | 6xxx Series (6061) |

|---|---|---|

| Weldability | Excellent | Good, requires control |

| Typical Weld Process | MIG / TIG | MIG / TIG |

| Cold Formability | Good to excellent | Moderate |

| Machinability | Moderate | Good |

| Heat Treatable | No | Yes (T tempers) |

This flexibility allows channels to be easily cut, mitered, drilled, gusseted, and welded into complex frame geometries, even in confined spaces inside hulls.

Chemical Composition of Typical Marine Alloys

alloy chemistry helps you select the right channel material for your load and corrosion requirements. The table below lists approximate compositions (wt%) for commonly used marine grades.

| Element | 5052 | 5083 | 5086 | 5456 | 6061 |

|---|---|---|---|---|---|

| Al | Balance | Balance | Balance | Balance | Balance |

| Mg | 2.2–2.8 | 4.0–4.9 | 3.5–4.5 | 4.7–5.5 | 0.8–1.2 |

| Mn | ≤0.10 | 0.4–1.0 | 0.2–0.7 | 0.5–1.0 | 0.15 max |

| Cr | 0.15–0.35 | 0.05–0.25 | 0.05–0.25 | 0.05–0.20 | 0.04–0.35 |

| Si | ≤0.25 | ≤0.40 | ≤0.40 | ≤0.25 | 0.4–0.8 |

| Fe | ≤0.40 | ≤0.40 | ≤0.50 | ≤0.40 | ≤0.7 |

| Cu | ≤0.10 | ≤0.10 | ≤0.10 | ≤0.10 | 0.15–0.40 |

| Zn | ≤0.10 | ≤0.25 | ≤0.25 | 0.25–0.60 | ≤0.25 |

| Others | ≤0.15 total | ≤0.15 total | ≤0.15 total | ≤0.15 total | ≤0.15 total |

High magnesium content in 5xxx alloys is the to their outstanding marine performance, providing solid solution strengthening without sacrificing corrosion resistance.

Typical Channel Dimensions and Technical Specifications

Marine aluminum channels are available in a range of sizes to accommodate differing load paths, spans, and design standards.

Common Dimensional Ranges

| Parameter | Typical Range |

|---|---|

| Overall Height H (mm) | 25 – 300 |

| Flange Width B (mm) | 15 – 125 |

| Web Thickness tᵥ (mm) | 2.0 – 12.0 |

| Flange Thickness tᶠ (mm) | 2.0 – 12.0 |

| Length (standard) | 6 m / 12 m |

| Tolerance on Height and Width | ±0.5 – ±1.0 mm (depending on size) |

| Straightness Tolerance | ≤ 1.5 mm per meter |

| Squareness of Web to Flange | ≤ 1° |

Example Section Properties

For quick reference, the following table shows typical section properties for representative marine channels. Values are approximate and vary by alloy and exact profile:

| Channel Size (H × B × tᵥ / tᶠ, mm) | Mass (kg/m) | Area (cm²) | Iₓ (cm⁴) | Section Modulus Zₓ (cm³) |

|---|---|---|---|---|

| 50 × 25 × 3 / 3 | 1.04 | 3.85 | 11 | 4.4 |

| 75 × 40 × 4 / 4 | 2.20 | 8.14 | 46 | 12.3 |

| 100 × 50 × 5 / 5 | 3.80 | 14.1 | 130 | 26.0 |

| 150 × 65 × 6 / 6 | 6.40 | 23.7 | 420 | 56.0 |

| 200 × 75 × 8 / 8 | 10.5 | 38.9 | 980 | 98.0 |

These values help designers quickly estimate deflection and stress under given loads for deck beams, stringers, and frame ribs.

Surface Treatments and Finishing Options

Although marine alloys are naturally corrosion resistant, additional finishing can boost durability and aesthetics.

| Treatment Type | Description | Benefits in Marine Frames |

|---|---|---|

| Mill Finish | As‑extruded surface | Cost‑effective, good for hidden frames |

| Anodizing (Marine) | Electrochemical oxide layer | Enhanced corrosion resistance, harder surface |

| Powder Coating | Thermoset resin coating | Color selection, UV resistance, added barrier |

| Epoxy Paint Systems | Multi‑coat marine paint | Long‑term immersion protection, easy touch‑up |

| Mechanical Polishing | Brushed or bright finish | Aesthetic for visible structural elements |

For heavy duty boat frames exposed to splash zones or partial immersion, pairing a marine‑grade alloy with a robust paint or anodizing system is strongly recommended.

Applications in Heavy Duty Boat Frame Design

Marine aluminum channels fit into almost every part of the boat’s structural skeleton. Some of the most common uses are outlined below.

Primary Structural Framing

| Frame Element | Typical Channel Use | Recommended Alloy |

|---|---|---|

| Longitudinal Stringers | Continuous C‑channels along hull bottom | 5083‑H116 / 5086‑H116 |

| Transverse Frames | Curved or segmented channels | 5083‑H116 |

| Keelson and Center Girders | Heavier channels with thicker webs | 5456‑H116 or 5086 |

| Deck Beams | Channels spanning beam‑to‑beam | 5083 / 5086 / 6061‑T6* |

* 6061‑T6 recommended mainly for non‑immersed deck framing with suitable coating.

Superstructure and Secondary Framing

| Component | Role of Channel Section | Notes |

|---|---|---|

| Cabin and Wheelhouse | Lightweight framing for walls and roofs | 5052 / 6061 for easier forming |

| Gunwales and Bulwarks | Edge stiffening, impact resistance | Heavier channels with rolled edges |

| Consoles and Seats | Hidden frames supporting molded modules | Smaller channels, easy weldment |

| Rail and Handrail Bases | Anchor points to decks and side structures | Often anodized for appearance |

Workboat and Commercial Vessel Uses

| Vessel Type | Example Channel Applications |

|---|---|

| Offshore Workboats | Robust deck framing, crane bases, towing bitt foundations |

| Patrol Boats | High‑stiffness hull frames, shock‑resistant deck supports |

| Passenger Ferries | Lightweight superstructure frames, canopy and walkway supports |

| Fishing Vessels | Frames for fish holds, winch supports, deckhouse structures |

In each case, channels provide a balance of rigidity, corrosion resistance, and fabrication simplicity that is difficult to achieve with other materials.

Design Considerations for Optimal Performance

When specifying Marine aluminum channels for heavy duty frames, a few design principles can significantly increase durability and safety.

| Design Factor | Recommendation |

|---|---|

| Alloy Selection | Use 5xxx alloys for immersed / wet zones; 6xxx for dry zones |

| Section Size | Match section modulus to bending and fatigue requirements |

| Weld Location | Place welds in lower‑stress regions of the channel web |

| Galvanic Corrosion | Isolate aluminum from stainless or carbon steel fittings |

| Drainage and Venting | Avoid trapped water inside channels or closed compartments |

| Fatigue Life | Avoid sharp notches; use smooth radii and proper gusseting |

Proper detailing of cutouts, brackets, and attachment points ensures that the natural advantages of aluminum channels are fully realized in long‑term operation.

Why Choose Marine aluminum channels for Your Next Build?

| Benefit Category | How Channels Add Value |

|---|---|

| Structural Performance | High stiffness‑to‑weight, excellent fatigue resistance |

| Durability | Strong marine corrosion resistance with suitable coatings |

| Build Efficiency | Easy cutting, forming, and welding for fast fabrication |

| Lifecycle Cost | Lower maintenance and fuel consumption than steel frames |

| Design Flexibility | Wide range of sizes, alloys, and custom profiles available |

Marine aluminum channels provide the structural backbone for modern boat and ship frames, delivering reliability and performance whether you are building a rugged workboat, a high‑speed patrol craft, or a premium recreational vessel. By selecting the right alloy, profile, and surface treatment, you can create a frame system that remains strong, light, and corrosion‑resistant throughout its service life.

Related Products

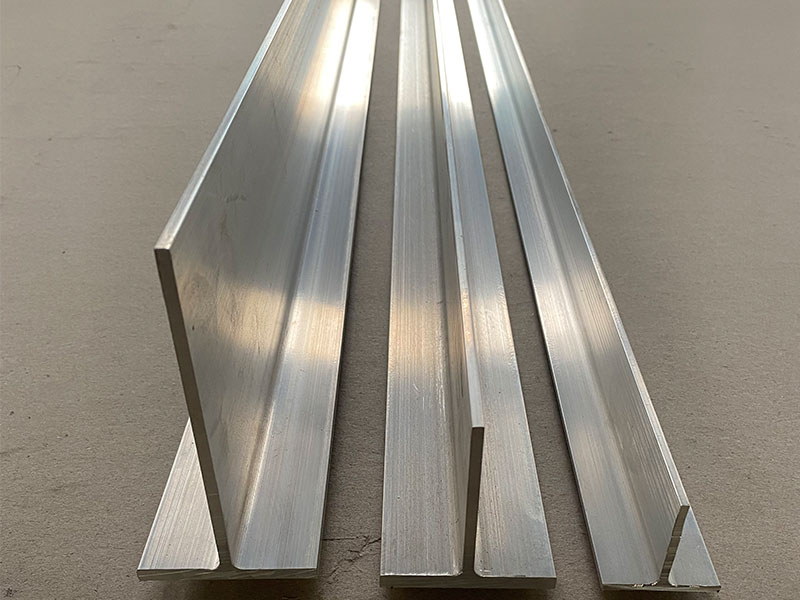

Marine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View DetailsMarine aluminum I-beams

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction.

View DetailsMarine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View Details6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

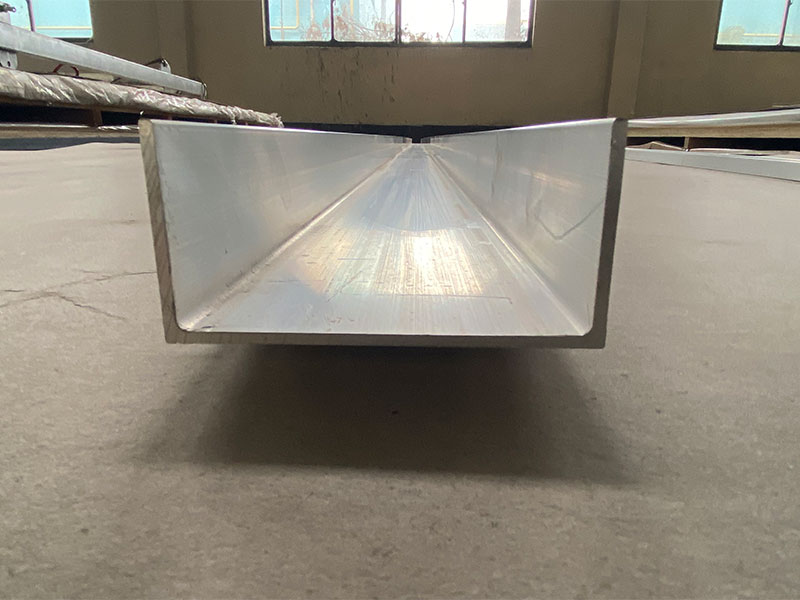

View DetailsMarine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View DetailsRelated Blog

6082 Marine Aluminum Rod & Bar for Custom Boat Frame Reinforcements

Marine aluminum is the ideal choice for lightweight, durable, and corrosion-resistant applications, particularly in the production of vessels that operate in harsh marine environments.

View Details5052 Marine Aluminum Angles for Custom Coastal Engineering

In the dynamic field of coastal engineering, material selection plays an indispensable role in the longevity, reliability, and safety of offshore and shoreline structures.

View DetailsMarine Aluminum Flat Bar for Offshore Boat and Platform Reinforcement

High-performance marine aluminum flat bars engineered for offshore boat and platform reinforcement applications. Steel-like strength, corrosion resistance, and optimal composition for harsh marine environments.

View Details6061 Marine Aluminum I Beams for Marine Frame and Hull Customization

When it comes to marine applications, the selection of materials is critical. An imbalance can not only affect the aesthetics of a vessel but compromise its safety and functionality as well.

View DetailsMarine Aluminum Rod & Bar for Lightweight Marine Frame Reinforcement

Marine structures demand materials that combine low weight, high strength, and long-term corrosion resistance in harsh saltwater environments. Marine aluminum rod and bar products are engineered specifically to meet these needs.

View Details5083 Marine Aluminum Angles for Heavy Duty Offshore Boat Hulls

In the demanding world of offshore marine engineering, selecting the right materials for constructing boat hulls is critical.

View Details

Leave a Message