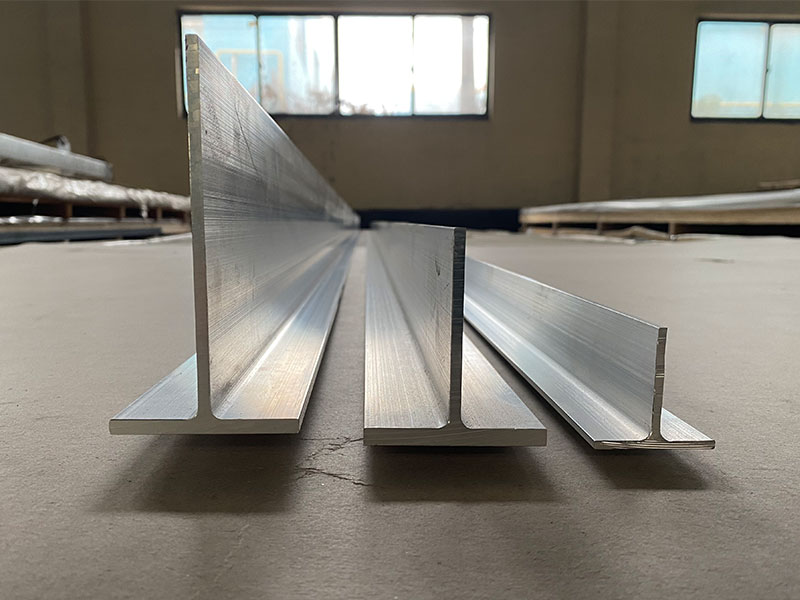

6061 Marine Aluminum Angles for High Strength Coastal Marine Parts

6061 Marine aluminum angles are premium-grade structural aluminum components widely used in the marine industry due to their exceptional strength, corrosion resistance, and versatility. Designed specifically to address the challenges faced in coastal and offshore environments, these aluminum angles provide longevity and robust performance even in harsh saline conditions.

6061 aluminum alloy, known for its balanced mechanical properties and excellent corrosion resistance, is extensively used in marine applications. When fabricated as angles, this alloy offers an ideal solution for framing, bracing, and structural support across various coastal marine parts, from boat hull reinforcements to dock and pier components.

Features

- High Strength-to-Weight Ratio: Enables structural durability without significant weight increase, essential for marine vessels.

- Superior Corrosion Resistance: The alloy resists oxidation and degradation caused by seawater and salt aerosols.

- Excellent Weldability: Simplifies fabrication and assembly into complex marine structures.

- Good Workability: Easy to machine and form for custom parts.

- Thermal and Electrical Conductivity: Useful for applications requiring effective heat and electrical transfer.

- Long Replacement Cycle: Saves maintenance costs over time in marine environments.

Chemical Composition of 6061 Alloy

| Element | Minimum (%) | Maximum (%) |

|---|---|---|

| Aluminum (Al) | Balance | Balance |

| Silicon (Si) | 0.4 | 0.8 |

| Iron (Fe) | 0.0 | 0.7 |

| Copper (Cu) | 0.15 | 0.40 |

| Manganese (Mn) | 0.0 | 0.15 |

| Magnesium (Mg) | 0.8 | 1.2 |

| Chromium (Cr) | 0.04 | 0.35 |

| Zinc (Zn) | 0.0 | 0.25 |

| Titanium (Ti) | 0.0 | 0.15 |

Technical Specifications for 6061 Marine aluminum angles

| Property | Specification |

|---|---|

| Temper | T6 (Solution heat-treated and artificially aged) |

| Thickness Range | 5 mm to 50 mm |

| Weight per unit length | Approx. 2.7 g/cm³ (varies by section size) |

| Standard Lengths | 6 meters |

| Tensile Strength | 290 MPa (min) |

| Yield Strength | 240 MPa (min) |

| Elongation | ≥ 8% (depending on thickness) |

| Hardness (Brinell) | 95 HB |

Marine-Specific Performance Data

| Parameter | Value | Comments |

|---|---|---|

| Salt Spray Corrosion | Minimal after 1000 hours exposure | Excellent seawater resistance |

| Weldability | Excellent | Suitable for MIG/TIG/Arc welding |

| Conductivity | 40-45 % IACS | Enables corrosion monitoring applications |

| Thermal Expansion Coefficient | 23.5 x 10⁻⁶ /°C | Compatible with marine composites |

| Density | 2.7 g/cm³ | Lightweight for structural weight fluency |

Applications of 6061 Marine aluminum angles in Coastal Marine Parts

| Application | Description | Advantages |

|---|---|---|

| Boat and Ship Framing | Used to construct internal and external frame parts | Adds rigidity and weight-efficiency |

| Bulkheads and Partitions | Provides corrosion-resistant internal bracing | Prevents rust and extends service life |

| Dock and Pier Structures | Sub-frames and support braces exposed to seawater | High strength minimizes deformation |

| Coastal Defense Equipment | Brackets, clips, and mounts for exposed systems | Maintains structural integrity |

| Marine Electrical Rails | Supports for wiring, ground connectors | Corrosion-resistant with excellent conductivity |

| Ladders and Railings | Lightweight, strong, and corrosion-resistant | Ensures safe access with minimal maintenance |

Advantages Over Other Materials

| Feature | 6061 Marine Aluminum Angulars | Steel Angles | Traditional Aluminum Angles |

|---|---|---|---|

| Weight | Lightweight (2.7 g/cm³) | Much heavier (>7.8 g/cm³) | Similar weight, but lower strength |

| Corrosion Resistance | Excellent in marine environments | Susceptible to rusting | Prone to corrosion without treatment |

| Fabrication Ease | Weldable and machinable | Difficult and heavier to weld | Easy but weaker material |

| Cost Efficiency | Moderate | Potentially cheaper but higher lifecycle cost | Economical but needs frequent replacement |

Related Products

Marine aluminum I-beams

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction.

View DetailsMarine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View DetailsMarine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View Details6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

View Details6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

View DetailsRelated Blog

6061 Marine Aluminum Z Shaped Sections for High Strength Boat Reinforcement

6061 Marine Aluminum Z Shaped Sections are purpose-designed extrusions used for structural reinforcement in marine and offshore applications. Made from 6061 aluminum alloy and formed into Z-profile sections, these members combine high strength.

View Details6061 T6 Marine Aluminum Flat Bar for Heavy Duty Boat Frame Parts

Strength, corrosion resistance, and durability of 6061 T6 Marine Aluminum Flat Bar – the ideal choice for heavy duty boat frame components ensuring longevity and performance in harsh marine environments.

View Details6061 Marine Aluminum Z Shaped Sections for Marine Frame Customization

In the marine industry's relentless quest for durability, corrosion resistance, and structural integrity, 6061 Marine Aluminum stands out as a premier choice—especially when customized in Z shaped sections for marine frameworks.

View Details6061 Marine Aluminum I Beams for High Performance Marine Engineering

The 6061 marine aluminum I beams are a premier choice for engineers and designers in the marine industry. Renowned for their strength, corrosion resistance, and versatility, these aluminum I beams are ideal for various applications.

View Details6061 T6 Marine Aluminum Flat Bar for Custom Boat Deck Design

6061 aluminum is a common structural alloy known globally for its versatility. When solution heat-treated and artificially aged to the T6 temper designation, it exhibits increased strength and hardness.

View Details6061 Marine Aluminum Angles for High Strength Coastal Marine Parts

6061 Marine Aluminum Angles are premium-grade structural aluminum components widely used in the marine industry due to their exceptional strength, corrosion resistance, and versatility.

View Details

Leave a Message