Marine Aluminum Channels for Marine Engineering and Custom Solutions

Marine aluminum channels are vital components for a wide range of applications in marine engineering. Specially engineered to withstand the unique challenges posed by marine environments, these products combine strength, lightweight properties, and excellent corrosion resistance.

Features

Lightweight Yet Strong: Marine aluminum offers significant weight savings compared to steel without compromising on strength, making it ideal for various marine applications.

Corrosion Resistance: The inherent properties of aluminum, specifically aluminum alloys used in marine channels, deliver exceptional resistance to corrosion caused by saltwater and harsh environmental conditions governing marine environments.

Versatility: Available in various shapes and sizes, these channels can be customized to meet specific engineering needs.

Easy Fabrication: Marine aluminum channels can be easily welded, cut, and machined, offering flexibility in construction and design processes.

Recyclable: They are environmentally friendly due to their high recyclability, reducing carbon and ecological footprints.

Applications

Marine aluminum channels have a variety of applications, including:

- Boat and Ship Construction: Used in the framework and superstructures of boats and ships,

- Aerospace Applications: Providing structural support in airborne marine vessels and other combos,

- Modular Platforms: Shaping dock systems, piers, walkways, workboats, and more,

- Support Structures: Ideal for integration with various marine system builds.

Technical Specifications

Chemical Composition

Below is the chemical composition often found in the Marine aluminum channels favorable for marine applications:

| Element | Mg (%) | Si (%) | Fe (%) | Zn (%) | Other (varies) | Description |

|---|---|---|---|---|---|---|

| 6061-T6 | 0.8 - 1.2 | 0.4 max | 0.7 max | 0.25 max | Cu (0.15-0.40), Cr (0.04-0.35) | Common marine alloy known for optimal combination of strength and resistance. |

| 5083 | 4.0 - 4.9 | 0.4 max | 0.5 max | 0.25 max | Mn (0.4 - 0.6), Cr (0.05 - 0.25) | Known for its outstanding resistance to seawater and extremely high strength. |

| 5052 | 2.2 - 2.8 | 0.25 max | 0.4 max | 0.10 max | Ni (0.10-0.20), Mn (0.10-0.50) | Low density, highly durable, with moderate strength. |

Technical Properties

| Parameters | 6061-T6 | 5083 | 5052 |

|---|---|---|---|

| Density (g/cm³) | 2.70 | 2.66 | 2.68 |

| Yield Strength (MPa) | 275 | 300 | 210 |

| Ultimate Tensile Strength (MPa) | 315 | 350 | 260 |

| Elongation % | 20 | 14 | 12 |

| Fatigue Strength (MPa) | 150 | 130 | 90 |

Alloy Tempering Conditions

Marine aluminum channels undergo specific alloy tempering and treatment processes, customizing their properties for specific applications. Significant temper conditions are included in the following table:

| Temper | Description | Notes |

|---|---|---|

| T6 | Solution heat-treated and artificially aged | Higher strength and hardness due to thermal treatment |

| H321 | Aged and stabilized condition | Good resistance to SCC (Stress Corrosion Cracking) under commercial buildings. |

| H116 | Protected against continuous corrosion | Preferable for structures constantly submerged or frequently splashed. |

Related Products

5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View DetailsMarine aluminum I-beams

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction.

View Details6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

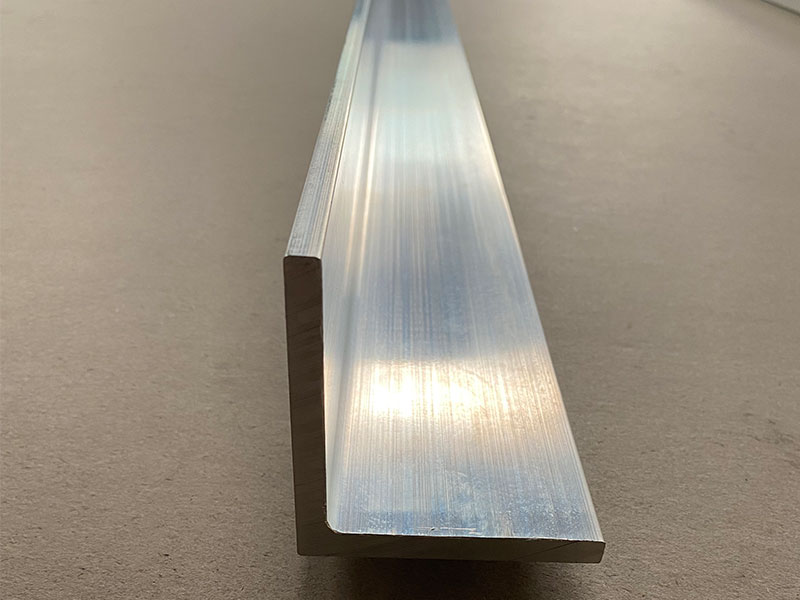

View DetailsMarine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

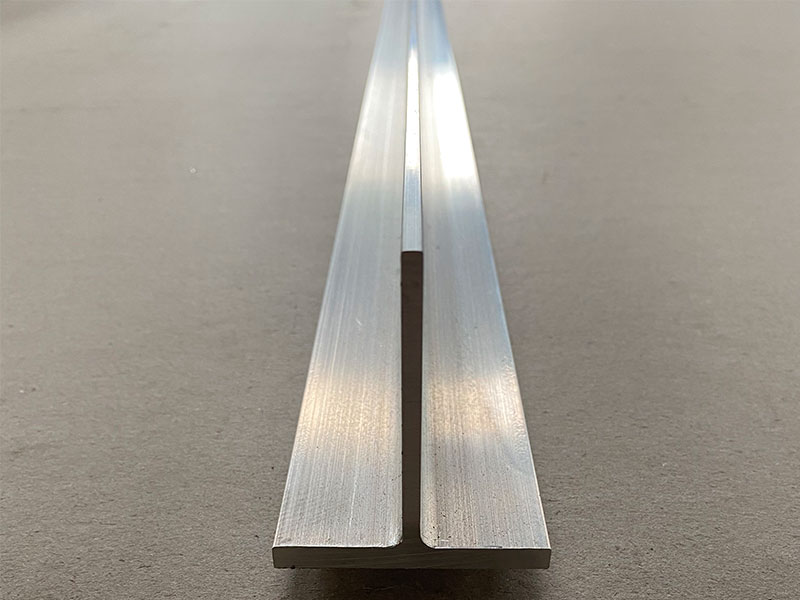

View DetailsMarine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View DetailsMarine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View DetailsRelated Blog

Marine Aluminum Z Shaped Sections for Seawater Proof Engineering Solutions

Unmatched advantages of Marine Aluminum Z Shaped Sections in seawater proof engineering solutions. Learn about their technical functions, applications, and why they are indispensable for marine infrastructure.

View DetailsMarine Aluminum Round Bar for Custom Marine Vessel Construction

Our premium Marine Aluminum Round Bars, specially engineered for custom marine vessel construction. Explore detailed specifications, alloy compositions, temper conditions, and industry standards that ensure superior corrosion resistance, structural integr

View DetailsMarine Aluminum Angles for Boat Hull Frame and Structural Support

When it comes to marine construction, selecting the right materials is crucial to ensure durability, corrosion resistance, and structural integrity.

View Details6061 Marine Aluminum Round Bar for Custom Marine Vessel Parts

When it comes to marine vessel construction and maintenance, the materials chosen play an integral part in their functionality, longevity, and structural integrity.

View Details5083 Marine Aluminum Z Shaped Sections for Custom Marine Boat Parts

When it comes to constructing durable, lightweight, and corrosion-resistant components for marine vessels, material selection is crucial. 5083 Marine Aluminum Z Shaped Sections offer an optimal combination of strength, formability.

View DetailsMarine Aluminum Round Bar for Custom Offshore Platform Fabrication

In the realm of offshore engineering, material selection is critical to ensuring the longevity, safety, and performance of marine structures.

View Details

Leave a Message