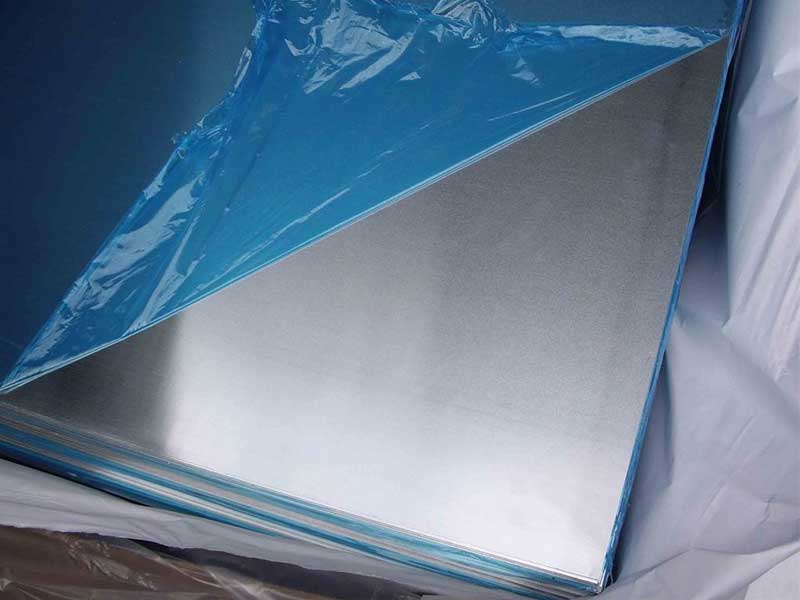

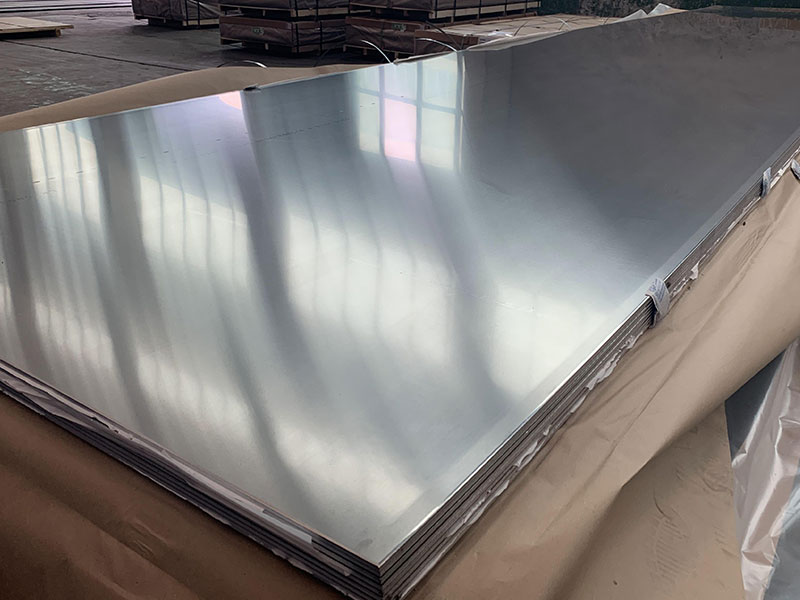

5083 marine grade aluminium plate

When it comes to marine construction and applications necessitating optimal performance in corrosive saltwater environments, 5083 marine grade aluminium plate stands out as one of the most reliable and versatile materials. Manufacture-centered around balancing properties such as corrosion resistance, strength, and formability, this aluminium alloy has become indispensable in modern shipbuilding, offshore structures, and specialized marine enclosures.

1. What Is 5083 Marine Grade Aluminium Plate?

5083 aluminium in marine applications is a non-heat-treatable aluminium–magnesium alloy classified under the 5xxx series. Recognized explicitly for superior corrosion resistance in chloride-rich environments, 5083 is an alloy designed into flat-rolled plate forms commonly referred to as "marine grade" due to stringent nautical product standards.

Chemical Composition

| Element | Content (%) | Typical Limits |

|---|---|---|

| Aluminium (Al) | Balance | Rest of alloy |

| Magnesium (Mg) | 4.0 - 4.9 | Principal strengthening alloying element |

| Manganese (Mn) | 0.4 - 1.0 | Improves mechanical strength |

| Chromium (Cr) | 0.05 - 0.25 | Enhances corrosion resistance |

| Iron (Fe) | ≤ 0.4 | Impurity usually minimized |

| Silicon (Si) | ≤ 0.4 | Found in trace quantities |

| Copper (Cu) | ≤ 0.1 | Kept low to preserve corrosion resistance |

This balanced chemistry mainly leverages magnesium for strength and protection, while manganese and chromium contribute to structural reliability and corrosion resistance in seawater.

2. Core Functions Tailored for the Marine Environment

High Corrosion Resistance under Saltwater Immersion

Thanks primarily to its substantial magnesium content, 5083 aluminium plate forms a tough, stable passive oxide film that withstands aggressive aqueous chloride ions encountered in seawater or marine atmospheres. The chromium addition also fortifies surface resistance, preventing pitting, exfoliation, and galvanic corrosion—a critical function for hulls and offshore platforms continually exposed to the elemental corrosion agents.

Excellent Weldability

Marine structures frequently require complex forming and fabrication processes, including weld joining numerous parts and sections. The 5083 alloy family adopts a strain-hardened and partially annealed state, typically temper H111 or H32, known for remarkable weldability without cracking or weakening. Plates temper-annealed to H116 are commonly specified to make sure strength is preserved and corrosion resistance remains robust post-welding.

Outstanding Strength-to-Weight Ratio

Especially important for vessels and offshore platforms competing against heavy steel counterparts, 5083 offers a favorable strength level (typically tensile strength 275–350 MPa bodies and yield of 145–215 MPa anneals), enabling builders to minimize deadweight without sacrificing safety or performance integrity. This trait allows efficient, fuel-saving designs important for both commercial and defense marine service.

3. Common Applications of 5083 Marine Aluminium Plate

Shipbuilding: Bulkheads, hull plates, decks, and the superstructure utilize 5083 to balance lengthy in-service life and resistance to marine wear plus mechanical strengthening needed under variable stressors and cargo conditions.

Offshore Platforms and Floating Structures: Critical platform decks, drill rigs, pontoons, and piping supports leverage 5083’s resilient combination of corrosion resistance and strength in corrosive offshore environments.

Boat and Yacht Manufacture: Extra strength and durability make it distinguished in luxury yachts and smaller fishing or sport boats where maintenance intervals benefit from aluminum’s resilient passive layer.

Saltwater Resistive Tanks and Containers: Storage tanks for fuels/products and environmental containment devices onboard ships rely on H116 or similar tempers oxides making them highly resistant to liquid-induced degradation.

Industrial and Military Buoyancy Devices and Submarine Hulls: Ductility and finite strength alongside corrosion protection enhance performance lifecycle where strict quality parameters mandate resistance to harsh exposure.

4. Technical Details - Standards and Seamless Specifications

Implementation Standards

The quality and uninterrupted consistency of 5083 marine aluminium grade plates must align closely with formalized evaluation standards ensuring safe operation which encapsulate but are not limited to:

| Standard | Region/Issuer | Designation/Details |

|---|---|---|

| ASTM B209 | ASTM Intl. | Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate |

| ISO 6361-1 | International Organization | Sheet / Plate Aluminium Alloy 5083 Part 1:ES5083 |

| EN 485-2 | European Standard | Certificate of Mechanical Properties in All Delivery Conditions |

| AA Alloy Design | Aluminum Association | Established chemical and mechanical guidelines |

| DNV/ABS/LR Rules | Classification Societies | Classification Rules relating to marine aluminum |

Temper Designations for 5083 Plates:

| Temper | Description | Typical Properties |

|---|---|---|

| H111 | Strain hardened only after rolling | Moderate strength, sensitive weld behavior |

| H112 | Factory strain hardening at low % | Limited deformation capability |

| H116 | Painted, anodized, stabilized with enhanced UV & corrosion resistance | Marine standard thermal treatment for hulls/detors |

| H321 | Strain hardened and stress relieved | Balanced toughness with strength |

Note: Tempering affects yield strength and ductility, and tailored selection is often dependent on fabrication processing and operational stresses.

5. Final Thoughts: Why 5083 Marine Grade Aluminium Stands Apart

Constructing steadfast footage and living up operational promise despite seawater's corrosive challenges require a synergistic solution — aluminium alloy compositions neither too weak to plummet nor too brittle for innovatively designed hybrids. 5083 marine grade aluminium plate delivers great dependability across multiple marine applications, blending corrosion resistance, structural strength, and favorable fabrication properties refined by strict manufacturing control standards.

Technically nurturing longevity without costly maintenance intervals bolsters economic and safety demands across the maritime industry. Whether forging shipping hulls, offshore foundations, or tailored seawater resistive gear, 5083 aluminium plates are the underwater champion bridging metallurgy and modern marine engineering advances.

For expert advice or precise alloy orders crafted for your marine project, contact us today — we specialize exclusively in high-grade marine aluminium products that deliver outstanding durability under saltwater exposure.

Related Products

Marine heavy duty aluminum plate

Marine Heavy Duty Aluminum Plates Sheets generally refer to thick aluminum alloy plates and heavy gauge sheets produced from marine-grade alloys such as 5083, 5086, 5059, and 5383.

View DetailsMarine aluminum steel clad plate

Aluminum / Steel Clad Plates consist of a sandwich construction in which a layer of marine-grade aluminum alloy is metallurgically bonded to a steel substrate.

View DetailsMarine 5083 aluminum plate

Marine 5083 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys and is classified as a non-heat-treatable alloy. Its high magnesium content (typically 4.0–4.9%) enhances its corrosion resistance, especially against seawater-related degradation such as pitting and stress corrosion cracking.

View DetailsMarine 5383 aluminum plate

The 5383 aluminum alloy belongs to the 5xxx series of aluminum-magnesium alloys known for remarkable resistance to marine corrosion and high strength.

View DetailsMarine 5059 aluminum plate

Marine 5059 Aluminum Plate is distinguished by its high magnesium content and carefully balanced alloying elements, designed to maximize strength without compromising corrosion resistance.

View DetailsMarine 5052 aluminum plate

Marine 5052 Aluminum Plate is noted for its exceptional resistance to corrosion caused by seawater, salt spray, and marine atmospheres.

View DetailsRelated Blog

3mm 5083 Marine Grade Aluminum Plate For Ship building

In the demanding world of shipbuilding, materials that combine strength, durability, and corrosion resistance are essential to construct vessels that can withstand harsh marine environments.

View DetailsMarine Grade Plate Aluminum Sheet 5083 O H116

When it comes to marine construction and offshore applications, selecting the right material is crucial. Marine Grade Aluminum Plate 5083 O H116 stands out as a top-tier solution, blending excellent mechanical properties, corrosion resistance.

View DetailsAluminum Alloy Plate 5083 H24 for Marine

OverviewAluminum Alloy Plate 5083 H24 is a high-performance material widely favored in marine engineering due to its excellent combination of high strength, exceptional corrosion resistance, and good weldability.

View Details5083 H116 marine grade aluminum alloy sheet plate

Superior corrosion resistance and high strength of 5083 H116 marine grade aluminum alloy sheet plate. Ideal for shipbuilding and marine structures, this alloy ensures durability in harsh sea conditions with excellent weldability and excellent workability.

View Details5083 marine grade aluminium plate

When it comes to marine construction and applications necessitating optimal performance in corrosive saltwater environments, 5083 marine grade aluminium plate stands out as one of the most reliable and versatile materials.

View DetailsHot Rol 5052 5083 Aluminum Plate Sheet for Boat

When it comes to marine aluminum, hot rolled 5052 and 5083 aluminum plate sheets hold a distinguished place, primarily due to their impeccable blend of strength, corrosion resistance, and formability — factors crucial for boat manufacturing.

View Details

Leave a Message