5052 Marine Aluminum Tubes for Marine Vessel Hull Construction

When it comes to building resilient marine vessels, selecting the right materials is crucial. One outstanding option is 5052 Marine Aluminum, widely recognized for its excellent corrosion resistance and structural integrity.

5052 Marine Aluminum

5052 Marine Aluminum is an alloy from the 5000 series, known for its outstanding resistance to seawater, making it a top choice in marine applications. This aluminum alloy comprises magnesium (2.5% to 3.5%) and small amounts of chromium and manganese, granting it enhanced performance whether it's subjected to fatigue, stress, or harsh environmental conditions.

Characteristics of 5052 Marine Aluminum

| Characteristic | Value |

|---|---|

| Chemical Composition | Al: Balance; Mg: 2.5% - 3.5%; Cr: 0.15% - 0.40% |

| Ultimate Tensile Strength | Approx. 210 MPa |

| Yield Strength | Approx. 193 MPa |

| Elongation (at break) | 12% |

| Density | 2.68 g/cm³ |

| Corrosion Resistance | Superior |

| Weldability | Excellent |

5052 aluminum tubes are adept at withstanding the rigorous demands of a dynamic marine environment, characterized by constant water contact, temperature variations, and salt exposure.

Marine Vessel Hull Construction: Implementation Standards

When implementing 5052 marine aluminum tubes into construction, certain standards ensure quality and reliability. Primarily, the Military Specification (MIL-DTL-32461) and American Society for Testing and Materials (ASTM) B928 provide a meticulous framework.

- Throat of weldment: Specific focus on joint thickness.

- Mechanical properties: Rigorous testing to ensure tensile strength certification.

- Formability guidelines: Adequate tempering processes towards final shaped products.

Alloy Tempering Conditions

Achieving the correct temper is crucial to enhancing the mechanical properties of 5052 aluminum. Currently, the available temper specifics under standards are:

- H32: Work hardened and partially annealed to optimize corrosion resistance while maintaining formability.

- H34: Cold worked substantially to increase strength levels, ensuring tougher hands that withstand external forces.

Tempering processes enhance ductility and exhibit significant workability, allowing rivets, kayak manufacturing, tubing, and crafting customized hulls tailored for specific purposes.

The Micro-Chemical Tradeoff

Studying chemical compatibility opens further discussion on marine efficiency versus increased strength requirements in sustenance materials. The vital constituents lie in balancing density with tensile integrity:

- Aluminum Oxide Layer Formation: Protective layer preventing further oxidation; ensures longevity.

- Anodizing Potential: Strengthened face against potential wear compared to untreated surfaces.

Advantages of 5052 Marine Aluminum in Hull Design

- Lightweight Characteristics: Reducing total vessel weight for better performance.

- Formability: The alloy is easily extruded or rolled into intricate shapes to optimize the hull design.

- Cost-Effectiveness: 5052's durability translates into fewer repairs over time, leading quickly into long-term savings.

Related Products

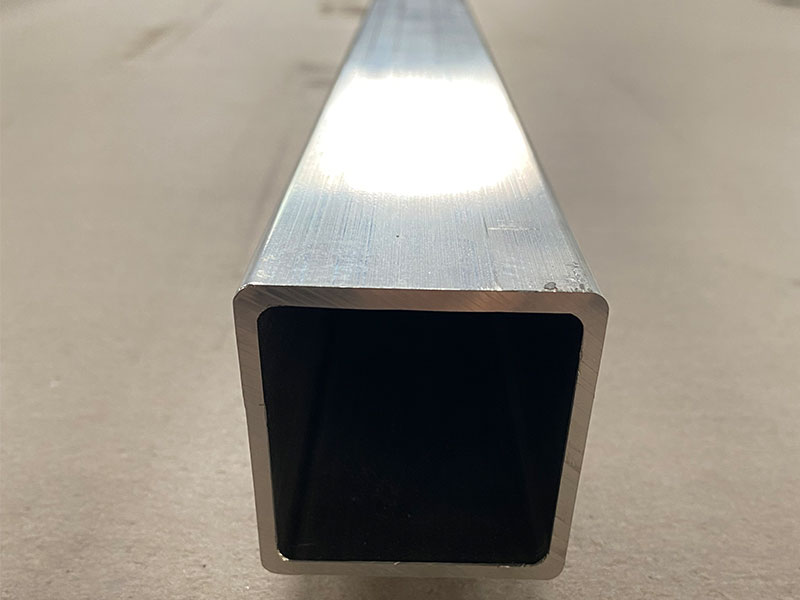

Marine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View DetailsMarine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View DetailsRelated Blog

5052 Marine Aluminum Tubes for Shipbuilding Engineering Parts

In the demanding world of shipbuilding engineering, materials are constantly put to the test by harsh marine environments. Among the myriad of metals options, 5052 Marine Aluminum Tubes is know for their remarkable balance of strength.

View Details5052 Marine Aluminum Tubes for Heavy Duty Marine Applications

When durability, corrosion resistance, and strength are paramount in marine environments, 5052 aluminum alloy tubes is know as the premium choice. Specifically engineered to meet the demanding specifications of heavy-duty marine applications.

View Details5052 Marine Aluminum Tubes for Marine Vessel Hull Construction

When it comes to building resilient marine vessels, selecting the right materials is crucial. One outstanding option is 5052 Marine Aluminum, widely recognized for its excellent corrosion resistance and structural integrity.

View Details5052 Marine Aluminum Round Tubes for Marine Applications

5052 Marine Aluminum Round Tubes are widely acclaimed within the marine industry for their excellent corrosion resistance, strength, and outstanding durability in harsh saltwater environments.

View Details

Leave a Message