5052 Marine Aluminum Round Tubes for Marine Applications

5052 Marine Aluminum Round Tubes are widely acclaimed within the marine industry for their excellent corrosion resistance, strength, and outstanding durability in harsh saltwater environments. This alloy has been specially optimized to deliver high performance under marine conditions, making it the material of choice for many marine structural components and equipment.

What is 5052 Aluminum Alloy?

5052 is an aluminum-magnesium alloy categorized under the non-heat-treatable alloys, characterized primarily by its magnesium content (2.2% to 2.8%). Its magnesium gives the alloy excellent corrosion resistance, particularly against seawater and industrial atmospheres, which is crucial in marine environments that constantly subject metals to saltwater and humidity.

Features of 5052 Marine Aluminum Round Tubes

| Feature | Description |

|---|---|

| Corrosion Resistance | Exceptional resistance to saltwater, preventing pitting and crevice corrosion, especially important in marine atmospheres. |

| Strength & Ductility | Medium-high strength combined with excellent ductility allows these tubes to endure mechanical stresses while maintaining formability. |

| Weldability | Excellent weldability through most common methods (TIG, MIG), enabling easy fabrication of marine structural components. |

| Lightweight | Low density (about 2.68 g/cm³) reduces vessel or structure overall weight, improving fuel efficiency and ease of handling. |

| Non-Magnetic | 5052 alloy is non-magnetic, suitable for sensitive electronic equipment installations in ships and submarines. |

| Surface Finish | Naturally forms an oxide layer for additional protection; can be anodized or polished for aesthetic or functional surface properties. |

| Temperature Stability | Maintains mechanical properties at moderately elevated temperatures, but recommended max operating temperature is about 150°C (302°F). |

Chemical Composition of 5052 Aluminum Alloy

| Element | Content (wt%) |

|---|---|

| Aluminum (Al) | Balance |

| Magnesium (Mg) | 2.2 – 2.8 |

| Chromium (Cr) | 0.15 – 0.35 |

| Iron (Fe) | ≤ 0.40 |

| Copper (Cu) | ≤ 0.10 |

| Manganese (Mn) | ≤ 0.10 |

| Silicon (Si) | ≤ 0.25 |

| Zinc (Zn) | ≤ 0.10 |

| Titanium (Ti) | ≤ 0.03 |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 228 – 310 MPa (33 – 45 ksi) |

| Yield Strength (0.2% offset) | 193 – 276 MPa (28 – 40 ksi) |

| Elongation at Break | 10 – 15 % |

| Hardness (Brinell) | 60 – 90 HB |

| Density | 2.68 g/cm³ |

| Melting Point | 607 - 652 °C (1125 - 1205 °F) |

Marine Applications of 5052 Aluminum Round Tubes

5052 aluminum round tubes are utilized in a variety of critical marine applications including:

1. Shipbuilding & Boat Construction

- Structural frameworks and supports

- Handrails and stanchions

- Fuel tanks and piping due to corrosion resistance

- Ladders and gangways

2. Offshore Platforms and Equipment

- Tubular scaffolding for rigs and platforms

- Cable conduits exposed to sea atmosphere

- Structural components in buoys and navigation aids

3. Marine Fittings and Accessories

- Marine-grade electrical enclosures and junction boxes

- Guard rails closely exposed to salt spray

- Trailer components for marine craft transport

4. Other Specialty Applications

- Submarine and underwater vehicle components where corrosion and weight are prime concerns

- Deck furnishings and mooring equipment where threat of rust and repetitive stress is high

Advantages over Other Marine Materials

| Comparison Aspect | 5052 Aluminum Round Tubes | Stainless Steel (Marine Grade) | Carbon Steel (Galvanized) |

|---|---|---|---|

| Corrosion Resistance | Excellent in seawater environments | Excellent, but heavier and can pit in stagnant seawater | Poor without maintenance |

| Weight | Low density (2.68 g/cm³) | Higher density (~7.8 g/cm³) | Heavy |

| Maintenance | Low - naturally forms oxide layer | Moderate, requires cleaning/polishing | High |

| Weldability | Excellent | Good but requires special electrodes | Good |

| Cost | Moderate | High | Low |

| Formability | High | Restricted due to hardness | High |

Available Sizes and Dimensions

We offer 5052 round tubes in standard diameters ranging from 10 mm (0.39 in) up to 200 mm (7.87 in), with wall thicknesses customized according to application requirements, from 1 mm to over 10 mm. Custom extrusions available upon request.

| Diameter Range | Wall Thicknesses | Length (stock sizes) |

|---|---|---|

| 10 mm – 200 mm | 1 mm – 10+ mm | 6 m, 12 m standard; custom cut-to-length services |

Fabrication & Machining Tips

- 5052 alloy is relatively easy to machine using conventional techniques.

- Avoid stress corrosion cracking during cutting and welding by cooling properly.

- Can be anodized or powder coated for additional corrosion protection and aesthetics if required.

- Best weld procedure involves clean coatings and use of suitable filler alloys (e.g., 5356).

5052 Marine Aluminum Round Tubes represent an optimal choice for marine applications, delivering unmatched corrosion resistance, solid mechanical properties, and excellent weldability—all crucial for long service life in demanding marine environments. Whether manufacturing boat structural members, offshore rig frames, or marine equipment tubular supports, 5052 aluminum round profiles is know for their performance, reliability, and ease of handling.

For orders, custom dimensions, or an engineering consultation regarding a particular marine project, contact our technical sales team, and we will provide personalized product recommendations based on detailed design parameters and environmental conditions.

Related Products

6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsMarine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

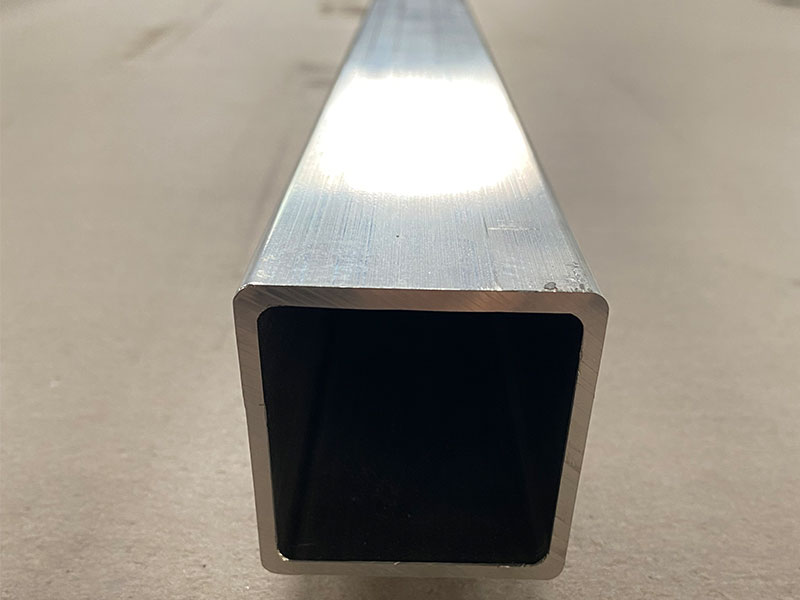

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View DetailsRelated Blog

5052 Marine Aluminum Round Tubes for Marine Applications

5052 Marine Aluminum Round Tubes are widely acclaimed within the marine industry for their excellent corrosion resistance, strength, and outstanding durability in harsh saltwater environments.

View Details5052 Marine Aluminum Tubes for Heavy Duty Marine Applications

When durability, corrosion resistance, and strength are paramount in marine environments, 5052 aluminum alloy tubes is know as the premium choice. Specifically engineered to meet the demanding specifications of heavy-duty marine applications.

View Details5052 Marine Aluminum Tubes for Shipbuilding Engineering Parts

In the demanding world of shipbuilding engineering, materials are constantly put to the test by harsh marine environments. Among the myriad of metals options, 5052 Marine Aluminum Tubes is know for their remarkable balance of strength.

View Details5052 Marine Aluminum Tubes for Marine Vessel Hull Construction

When it comes to building resilient marine vessels, selecting the right materials is crucial. One outstanding option is 5052 Marine Aluminum, widely recognized for its excellent corrosion resistance and structural integrity.

View Details

Leave a Message