5383 Marine Aluminum Plate

5383 marine aluminum plate is a high‑strength, corrosion‑resistant aluminum‑magnesium alloy designed for demanding shipbuilding and offshore environments. With superior weldability, excellent seawater resistance, and stable mechanical properties in both thin and thick gauges, 5383 is ideal for hull plating, decks, superstructures, and high‑load marine components where long-term durability and weight reduction are critical.

5383 is a specialized marine‑grade aluminum alloy developed as an enhanced alternative to the widely used 5083 alloy. By optimizing its magnesium content and trace elements, 5383 delivers:

- Higher yield and tensile strength than standard 5083

- Improved resistance to stress‑corrosion cracking and pitting in seawater

- Stable performance after welding and forming

Its combination of lightweight construction, strong structural capability, and long service life makes 5383 a preferred solution for modern shipyards targeting lower fuel consumption and reduced maintenance.

Features & Benefits

| Feature | Benefit in Marine Service |

|---|---|

| High strength-to-weight ratio | Enables thinner plates, reduces vessel weight, improves speed and fuel efficiency |

| Excellent seawater corrosion resistance | Extends hull and deck life, minimizes protective coating and repair costs |

| Superior weldability | Clean, crack‑resistant welds with minimal loss of strength in heat‑affected zones |

| Good fatigue resistance | Reliable under cyclic wave loading and vibration |

| Enhanced performance over 5083 | Higher proof strength and better structural margins, especially in high‑load regions |

| Non‑heat‑treatable alloy | Properties achieved via cold work; stable in service, no overaging risk |

| Good formability | Suitable for curved hull sections, decks, and superstructure panels |

| Wide size availability | From thin sheet for interiors to thick plate for hulls, keels, and stiffeners |

Typical Applications in the Marine Industry

| Application Area | Typical Use of 5383 Plate |

|---|---|

| Ship hull structures | Bottom shell, side shell, bow sections, stern structures, bilge strakes |

| Decks & superstructures | Main decks, weather decks, bridge decks, accommodation blocks, wheelhouses |

| High‑speed vessels | Patrol boats, fast ferries, crew boats, workboats requiring light yet strong hulls |

| Offshore structures | Helidecks, platforms walkways, accommodation modules, gangways |

| Naval & defense craft | Corrosion‑resistant hulls and decks with improved structural performance |

| Ramps & vehicle decks | Ro‑Ro ramps, loading platforms, car decks with high fatigue and impact loading |

| Tanks & enclosures | Ballast tanks, fresh‑water tanks, protective housings, enclosures for marine equipment |

| Inland watercraft | River boats, barges, service vessels requiring low maintenance and long service life |

Chemical Composition of 5383 Alloy

Typical composition values; specific limits may vary by standard (e.g., EN, ASTM, or classification society rules).

| Element | Typical Range (%) | Function / Effect |

|---|---|---|

| Mg | 4.3 – 5.2 | Primary strengthening element; enhances corrosion resistance in seawater |

| Mn | 0.4 – 1.0 | Improves strength, grain refinement, and toughness |

| Si | ≤ 0.40 | Controlled to maintain weldability and toughness |

| Fe | ≤ 0.40 | Kept low to avoid loss of corrosion resistance and ductility |

| Cr | 0.05 – 0.25 | Contributes to resistance against stress‑corrosion cracking |

| Ti | ≤ 0.15 | Grain refiner, helps maintain uniform mechanical properties |

| Cu | ≤ 0.10 | Restricted to maintain exceptional corrosion resistance |

| Zn | ≤ 0.25 | Limited to avoid susceptibility to stress‑corrosion cracking |

| Others | ≤ 0.05 each / 0.15 total | Trace elements maintained within strict limits |

| Al | Balance | Base metal providing low density and natural oxide protection |

Temper Designations and Processing

5383 is a non‑heat‑treatable aluminum‑magnesium alloy. Strength is achieved primarily through cold work (strain hardening). The most common tempers for marine plate are:

| Temper | Description | Typical Use Case in Marine Construction |

|---|---|---|

| O | Annealed, softest condition | Tight forming, complex curvature, deep drawing, subsequent welding |

| H111 | Slightly strain‑hardened | General hull plating and deck where good forming and welding are needed |

| H116 | Strain‑hardened, low‑temperature stabilized; optimized for marine service | Hull and deck plating in continuous seawater exposure |

| H321 | Strain‑hardened and stabilized | Highly stressed structural regions requiring stable mechanical properties |

The H116 and H321 tempers are commonly specified by ship classification societies (such as BV, DNV, ABS, LR) for critical marine structures.

Mechanical Properties of 5383 Marine Plate

Indicative values at room temperature; actual properties depend on thickness, temper, and specification.

Typical Mechanical Properties (Plate, ~10–25 mm)

| Property | Unit | 5383‑H116 / H321 (Typical) |

|---|---|---|

| Tensile strength, Rm | MPa | 300 – 340 |

| 0.2% proof strength, Rp0.2 | MPa | 200 – 260 |

| Elongation (A50) | % | 10 – 16 |

| Brinell hardness (HBW) | – | 85 – 100 |

| Modulus of elasticity | GPa | ~70 |

| Poisson’s ratio | – | ~0.33 |

| Density | g/cm³ | ~2.66 |

Physical & Thermal Characteristics

| Parameter | Value / Range | Notes |

|---|---|---|

| Melting range | ~570 – 640 °C | Typical for Al‑Mg alloys |

| Thermal conductivity | ~120 – 135 W/m·K | Assists in rapid heat dissipation in marine structures |

| Electrical conductivity | ~28 – 32 % IACS | Lower than pure Al due to Mg and other alloying elements |

| Coefficient of thermal expansion | ~23 × 10⁻⁶ /K (20–100 °C) | Important for joint design and mixed‑material structures |

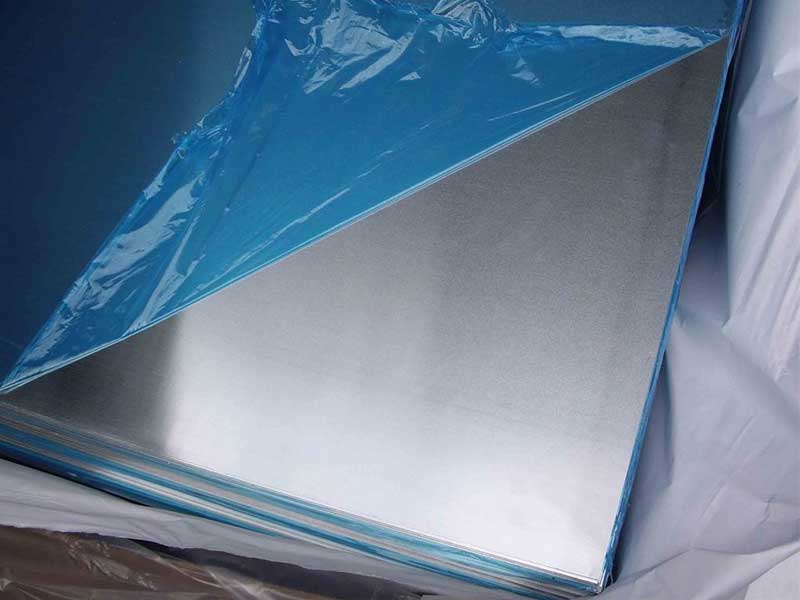

Plate Dimensions and Supply Range

Supply capabilities vary by mill and classification requirements, but typical commercial offerings are:

| Parameter | Typical Range |

|---|---|

| Thickness | 3 – 80 mm (marine plate focus) |

| Width | 1000 – 3000 mm |

| Length | 2000 – 12000 mm |

| Surface condition | Mill finish, shot‑blasted, primed (on request) |

| Edge condition | Mill edge, saw‑cut, or machined edges |

Custom dimensions and pre‑cut shapes for panels, bulkheads, and formed hull sections are often supplied to reduce fabrication time at the shipyard.

Weldability and Joining Performance

5383 is specifically engineered for excellent weldability using standard marine welding processes.

| Aspect | Details |

|---|---|

| Recommended processes | MIG (GMAW), TIG (GTAW), friction stir welding (FSW) |

| Typical filler metals | 5356, 5183, or compatible Al‑Mg fillers suited for marine exposure |

| Weld strength | High joint efficiency, particularly with 5183 filler |

| Heat‑affected zone | Limited softening; properties remain suitable for primary structures |

| Post‑weld treatment | Normally no heat treatment required; straightening and inspection as standard |

In practice, 5383 demonstrates improved post‑weld strength compared with conventional 5083, allowing more confident use in high‑load hull and deck joints.

Corrosion Resistance in Marine Environments

The alloy’s high magnesium content, controlled iron and copper levels, and appropriate stabilizing elements contribute to excellent resistance in:

| Environment | Performance of 5383 Plate |

|---|---|

| Open seawater (immersed) | Very good resistance to pitting and general corrosion |

| Splash and tidal zones | Strong performance under cyclic wet‑dry conditions |

| Marine atmosphere and salt fog | Low corrosion rate; suitable for decks and superstructures |

| Brackish and harbor waters | Reliable service with standard marine coatings and maintenance |

| Galvanic coupling with steel | Requires proper insulation and coating to prevent bimetallic attack |

A suitable paint or coating system is still recommended for hulls and decks to further extend life, especially in abrasive conditions or where fouling control is required.

Formability, Machinability, and Fabrication

| Property | Characteristics in 5383 |

|---|---|

| Formability | Good; H111 and O tempers allow tight bending and rolling for hull curvature |

| Machinability | Comparable to other Al‑Mg alloys; clean cutting with correct tooling |

| Cutting | Plasma, waterjet, laser (for thinner gauges), and mechanical cutting |

| Surface prep | Degreasing and light brushing or blasting prior to welding and coating |

The alloy’s balance of strength and ductility supports efficient fabrication with minimal risk of cracking during forming or welding.

Comparison: 5383 vs 5083 for Marine Use

| Property / Aspect | 5383 Marine Plate | 5083 Marine Plate |

|---|---|---|

| Strength (yield) | Higher | Standard baseline for Al‑Mg marine |

| Weld strength retention | Improved | Good, but generally lower than 5383 |

| Corrosion resistance | Excellent, optimized for marine | Excellent |

| Typical tempers for hull plate | H116 / H321 | H116 / H321 |

| Structural efficiency | Higher due to improved strength | Very good |

| Application trend | Increasing use in new builds | Widely used, benchmark alloy |

Shipyards often choose 5383 where classification and design rules allow, to reduce structural weight or to gain additional safety margins without increasing thickness.

Why Choose 5383 Marine Aluminum Plate

For shipbuilders, naval architects, and offshore engineers aiming to balance safety, performance, and lifecycle cost, 5383 marine aluminum plate offers a highly effective solution:

- Supports lighter, faster, and more fuel‑efficient vessels

- Delivers reliable long‑term corrosion resistance in harsh seawater conditions

- Provides excellent weldability and structural performance after fabrication

- Compatible with established marine design practices and classification standards

By upgrading from traditional alloys to 5383, marine projects can achieve higher structural efficiency and more durable service, particularly in demanding hull and deck applications.

Related Products

Marine 5083 aluminum plate

Marine 5083 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys and is classified as a non-heat-treatable alloy. Its high magnesium content (typically 4.0–4.9%) enhances its corrosion resistance, especially against seawater-related degradation such as pitting and stress corrosion cracking.

View DetailsMarine 5086 aluminum plate

5086 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys. Its hallmark is a high magnesium content—generally between 4.0% and 4.9%—which delivers enhanced corrosion resistance, particularly against saltwater and marine atmospheric conditions.

View DetailsMarine 5052 aluminum plate

Marine 5052 Aluminum Plate is noted for its exceptional resistance to corrosion caused by seawater, salt spray, and marine atmospheres.

View DetailsMarine 5059 aluminum plate

Marine 5059 Aluminum Plate is distinguished by its high magnesium content and carefully balanced alloying elements, designed to maximize strength without compromising corrosion resistance.

View DetailsMarine 5383 aluminum plate

The 5383 aluminum alloy belongs to the 5xxx series of aluminum-magnesium alloys known for remarkable resistance to marine corrosion and high strength.

View DetailsMarine aluminum steel clad plate

Aluminum / Steel Clad Plates consist of a sandwich construction in which a layer of marine-grade aluminum alloy is metallurgically bonded to a steel substrate.

View DetailsRelated Blog

7075 auminum marine plates hard aluminum plates

7075 aluminum marine plates are high-strength, durable, and corrosion-resistant aluminum alloy plates predominantly used in demanding marine environments. Known for their mechanical properties.

View Details6063 aluminum sheet plate for ship building

When it comes to modern shipbuilding, selecting the right materials is a balancing act between durability, weight, corrosion resistance, and cost-efficiency.

View DetailsMarine grade aluminium plate

When contemplating the construction of robust vessels or marine equipment, selecting the right materials is more significant than ever. Among the myriad options available, marine grade aluminium plate stands out due to its fortitude against corrosion.

View DetailsManufactures aluminum marine alloy plate 5083 5086 o h111 h321

Aluminum marine alloy plates such as 5083 and 5086 are extensively used in maritime applications due to their exceptional corrosion resistance, high strength, and excellent workability.

View DetailsMarine aluminum plate 5005 5052 color coated

In the marine industry, where reliability meets aesthetics, Aluminum Plate 5005 and 5052 color coated options have taken the forefront as building materials. With undeniably strength, corrosion resistance, and a visually appealing surface.

View DetailsMarine Grade Aluminum Plate 5083

When it comes to building robust, durable, and corrosion-resistant marine vessels and offshore structures, Marine Grade Aluminum Plate 5083 stands as a premier choice in the industry.

View Details

Leave a Message