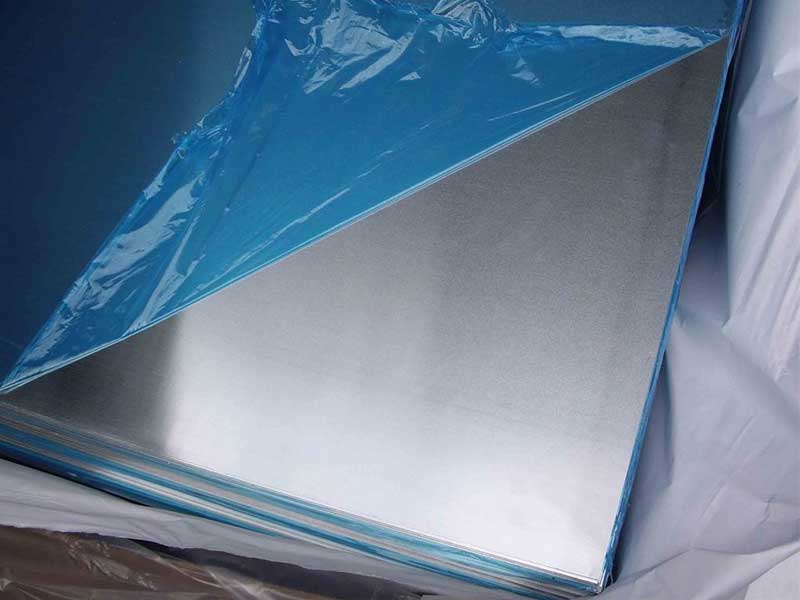

5052 5083 6063 h111 h22 h32 marine grade aluminum sheet plate

Marine projects demand materials that are lightweight, corrosion‑resistant, and reliable under harsh, salt‑water conditions. Among the most trusted options are the marine grade aluminum alloys 5052, 5083, and 6063 in tempers such as H111, H22, and H32.

| Alloy | Series | Main Alloying Element | Typical Use in Marine Field | Strength Level* | Corrosion Resistance* |

|---|---|---|---|---|---|

| 5052 | 5xxx | Magnesium (Mg) | Small boats, panels, fuel & water tanks, cabins | Medium | Very good |

| 5083 | 5xxx | Magnesium + Mn, Cr | Hulls, decks, superstructures, cryogenic & pressure use | High (non‑heat‑treat) | Excellent |

| 6063 | 6xxx | Magnesium + Silicon | Marine profiles, trims, frames, decorative components | Medium (heat‑treat) | Good |

*Relative comparison within common wrought aluminum alloys.

Typical Tempers: H111, H22, H32

“Temper” describes the mechanical and metallurgical condition of the sheet or plate.

| Temper | Process Route | Characteristics | Typical Use Case |

|---|---|---|---|

| H111 | Strain‑hardened, lightly worked | Slightly higher strength than annealed; good formability | Hull plating, cold‑formed panels |

| H22 | Strain‑hardened, then partially annealed | Balanced strength and ductility; moderate forming | Decorative parts, stiffeners, fairings |

| H32 | Strain‑hardened and stabilized (half‑hard) | Higher strength with acceptable formability | Structural panels, decks, high‑load components |

Chemical Composition (Typical Ranges, wt%)

Alloy 5052

| Element | Content (wt%) |

|---|---|

| Mg | 2.2 – 2.8 |

| Mn | ≤ 0.10 |

| Fe | ≤ 0.40 |

| Si | ≤ 0.25 |

| Cr | 0.15 – 0.35 |

| Cu | ≤ 0.10 |

| Zn | ≤ 0.10 |

| Ti | ≤ 0.15 |

| Others | ≤ 0.05 each / 0.15 total |

| Al | Balance |

Alloy 5083

| Element | Content (wt%) |

|---|---|

| Mg | 4.0 – 4.9 |

| Mn | 0.40 – 1.0 |

| Fe | ≤ 0.40 |

| Si | ≤ 0.40 |

| Cr | 0.05 – 0.25 |

| Cu | ≤ 0.10 |

| Zn | ≤ 0.25 |

| Ti | ≤ 0.15 |

| Others | ≤ 0.05 each / 0.15 total |

| Al | Balance |

Alloy 6063

| Element | Content (wt%) |

|---|---|

| Mg | 0.45 – 0.90 |

| Si | 0.20 – 0.60 |

| Fe | ≤ 0.35 |

| Cu | ≤ 0.10 |

| Mn | ≤ 0.10 |

| Cr | ≤ 0.10 |

| Zn | ≤ 0.10 |

| Ti | ≤ 0.10 |

| Others | ≤ 0.05 each / 0.15 total |

| Al | Balance |

Mechanical Properties (Typical Values, Room Temperature)

Actual properties depend on thickness, product form, and manufacturing standard. The following are indicative values.

Yield Strength & Tensile Strength

| Alloy – Temper | Yield Strength Rp0.2 (MPa) | Tensile Strength Rm (MPa) | Elongation A50 (%) |

|---|---|---|---|

| 5052‑H111 | 110 – 150 | 215 – 260 | 10 – 16 |

| 5052‑H32 | 160 – 200 | 215 – 260 | 7 – 12 |

| 5083‑H111 | 145 – 215 | 275 – 345 | 10 – 16 |

| 5083‑H32 | 215 – 255 | 305 – 355 | 8 – 12 |

| 6063‑H22* | 110 – 150 | 150 – 195 | 8 – 15 |

*6063 is more commonly supplied in T5/T6 tempers for extrusions; above values indicate typical ranges where H22 is applied to sheet/plate.

Physical Properties

| Property | 5052 | 5083 | 6063 |

|---|---|---|---|

| Density (g/cm³) | ~2.68 | ~2.66 | ~2.70 |

| Modulus of Elasticity (GPa) | ~70 | ~70 | ~69 |

| Melting Range (°C) | 607 – 650 | 570 – 640 | 615 – 655 |

| Thermal Conductivity (W/m·K) | ~138 | ~121 | ~201 |

| Electrical Conductivity (% IACS) | 32 – 35 | 28 – 32 | 45 – 52 |

Features for Marine Use

Corrosion Resistance

| Alloy | Seawater Corrosion Performance | Notes |

|---|---|---|

| 5052 | Very good | Ideal for fuel tanks, deck housings |

| 5083 | Excellent | Preferred for hulls and load‑bearing parts |

| 6063 | Good, especially with anodizing | Best used for profiles and non‑primary structure |

Highlights:

- High magnesium content in 5052 and 5083 forms a stable passive film in seawater, limiting pitting and crevice corrosion.

- 6063 offers good resistance but is often protected further by anodizing or coatings for long‑term marine exposure.

Strength vs Weight

| Alloy | Relative Strength | Weight Advantage vs Steel |

|---|---|---|

| 5052 | Medium | ~65–70% lighter |

| 5083 | High (non‑heat‑treat) | ~65–70% lighter |

| 6063 | Medium | ~65–70% lighter |

The combination of high specific strength and low density reduces hull weight, improves fuel efficiency, and allows higher payloads or speed.

Formability and Weldability

| Alloy – Temper | Cold Formability | Weldability (MIG/TIG) | Remarks |

|---|---|---|---|

| 5052‑H111 | Excellent | Excellent | Suitable for deep drawing and complex bending |

| 5052‑H32 | Good | Excellent | Balanced strength and forming |

| 5083‑H111 | Very good | Excellent | Common in shaped hull panels |

| 5083‑H32 | Good | Very good | Used where higher strength is needed after forming |

| 6063‑H22 | Good | Very good | Particularly good for welded frames and profiles |

Typical Dimensions and Supply Range

| Parameter | Typical Range |

|---|---|

| Thickness (sheet) | 0.5 – 6.0 mm |

| Thickness (plate) | 6.0 – 200 mm (depending on alloy) |

| Width | 1000 – 2500 mm (custom on request) |

| Length | 2000 – 12000 mm or cut‑to‑size |

| Surface | Mill finish, brushed, anodized, coated |

Major Marine Applications

Shipbuilding and Boat Construction

| Component | Preferred Alloys / Tempers | Reasons |

|---|---|---|

| Hull plating (workboats, ferries, patrol boats) | 5083‑H111 / H32 | High strength, excellent seawater resistance |

| Decks and superstructures | 5083‑H111, 5052‑H32 | Weight saving, good stiffness, easy welding |

| Cabins and interior panels | 5052‑H32, 6063 (profiles) | Good appearance, ease of fabrication |

| Ribs, frames, stiffeners | 5083‑H32, 5052‑H32 | Structural support with low weight |

| Handrails, trims, window frames | 6063‑H22 or T5/T6 extrusions | Smooth surface, high quality anodized finish |

Offshore and Port Equipment

| Application | Typical Alloy | Requirements Met |

|---|---|---|

| Gangways and ramps | 5083‑H32, 5052‑H32 | Strength, slip‑resistant surfaces, lighter weight |

| Accommodation modules | 5052‑H32 | Corrosion resistance, ease of installation |

| Containerized equipment housings | 5052‑H32, 6063 profiles | Weather resistance, weldability |

| Dockside structures, pontoons | 5083‑H111/H32 | Continuous seawater exposure, fatigue resistance |

Tanks, Piping, and Special Components

| Component | Alloy / Temper | Advantages |

|---|---|---|

| Fuel tanks | 5052‑H32 | Good resistance to fuel and seawater, easy forming |

| Fresh‑water tanks | 5052‑H32 | Hygienic, non‑rusting |

| Cryogenic tanks (LNG, LPG) | 5083‑H321 / H111 | High toughness at low temperature, pressure resistance |

| Lightweight ducting & covers | 5052‑H111, 6063 | Thin‑gauge forming, good stiffness‑to‑weight |

Selection Guide: 5052 vs 5083 vs 6063

| Design Requirement | Recommended Choice |

|---|---|

| Primary hull, decks, and high‑load parts | 5083‑H111 / H32 |

| General marine panels, tanks, cabins | 5052‑H32 or H111 |

| Extruded frames, rails, decorative parts | 6063‑H22 or T5/T6 |

| Best corrosion resistance in seawater | 5083 (any marine temper) |

| Highest formability at reasonable strength | 5052‑H111 |

Processing and Fabrication Notes

| Process | Suitability & Notes |

|---|---|

| Cutting | All alloys cut cleanly by shearing, sawing, plasma, laser, or waterjet |

| Bending | H111 tempers offer easiest bending; thicker H32 plates may require larger bend radius |

| Welding | Excellent with MIG/TIG; 5xxx filler wires (e.g., 5183, 5356) commonly used |

| Surface finish | Mill finish for structural parts; anodizing or painting for exposed decorative areas |

Proper joint design and selection of compatible filler metals help maintain corrosion resistance and mechanical properties in marine environments.

5052, 5083, and 6063 marine grade aluminum sheet and plate in tempers H111, H22, and H32 offer a versatile toolkit for shipyards, boat builders, and offshore engineers:

- 5052: a workhorse alloy for tanks, panels, and formed components, combining good strength, formability, and corrosion resistance.

- 5083: the benchmark for high‑strength, corrosion‑resistant marine structures such as hulls, decks, and cryogenic tanks.

- 6063: ideal for profiles and decorative or non‑primary structural elements, especially where anodized appearance is important.

By matching alloy and temper to the required strength, formability, and exposure conditions, designers can achieve durable, lightweight, and cost‑effective marine constructions that perform reliably over a long service life.

Related Products

Marine 5383 aluminum plate

The 5383 aluminum alloy belongs to the 5xxx series of aluminum-magnesium alloys known for remarkable resistance to marine corrosion and high strength.

View DetailsMarine 5086 aluminum plate

5086 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys. Its hallmark is a high magnesium content—generally between 4.0% and 4.9%—which delivers enhanced corrosion resistance, particularly against saltwater and marine atmospheric conditions.

View DetailsMarine aluminum steel clad plate

Aluminum / Steel Clad Plates consist of a sandwich construction in which a layer of marine-grade aluminum alloy is metallurgically bonded to a steel substrate.

View DetailsMarine 5083 aluminum plate

Marine 5083 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys and is classified as a non-heat-treatable alloy. Its high magnesium content (typically 4.0–4.9%) enhances its corrosion resistance, especially against seawater-related degradation such as pitting and stress corrosion cracking.

View DetailsMarine 5059 aluminum plate

Marine 5059 Aluminum Plate is distinguished by its high magnesium content and carefully balanced alloying elements, designed to maximize strength without compromising corrosion resistance.

View DetailsMarine heavy duty aluminum plate

Marine Heavy Duty Aluminum Plates Sheets generally refer to thick aluminum alloy plates and heavy gauge sheets produced from marine-grade alloys such as 5083, 5086, 5059, and 5383.

View DetailsRelated Blog

Marine grade 5052 alloy aluminium sheet plate

Features — why choose 5052 for marine applicationsExcellent resistance to seawater and marine atmospheres (better than 3003, 6061 in chloride environments).Good fatigue strength and impact resistance for thin-gauge structural components.

View Details5052 H34 Aluminum Plate for Boat

When it comes to marine applications, specifically boat building and repair, selecting the right aluminum material is critical for long-lasting performance, corrosion resistance, and structural integrity.

View Details5052 h111 alloy aluminum marine plate

When it comes to marine aluminum plates, performance and reliability are non-negotiable qualities due to the challenging environments they encounter—saltwater corrosion, fluctuating temperatures, and mechanical stresses.

View DetailsMarine aluminum plate 5005,5052 color coated

The Versatility of Marine Aluminum Plate 5005 and 5052: Beyond the SurfaceMarine aluminum plates are crucial materials in various maritime applications, offering a unique blend of structural integrity, corrosion resistance, and aesthetic appeal.

View DetailsMarine aluminum plate 5005 5052 color coated

In the marine industry, where reliability meets aesthetics, Aluminum Plate 5005 and 5052 color coated options have taken the forefront as building materials. With undeniably strength, corrosion resistance, and a visually appealing surface.

View Details5052 5083 6063 h111 h22 h32 marine grade aluminum sheet plate

Marine projects demand materials that are lightweight, corrosion‑resistant, and reliable under harsh, salt‑water conditions. Among the most trusted options are the marine grade aluminum alloys 5052, 5083, and 6063 in tempers such as H111, H22, an.

View Details

Leave a Message