5083 Marine Aluminum Fencing and Railings for Durable Coastal Railings

Aluminum alloy 5083 is widely regarded as one of the best materials for marine applications, particularly for fencing and railings exposed to harsh coastal environments. Its excellent corrosion resistance, superior mechanical properties, and ease of fabrication establish 5083 aluminum as an ideal solution for durable coastal railings.

5083 aluminum belongs to the aluminum-magnesium alloy family. It is known for exceptional resistance to seawater corrosion and excellent strength-to-weight ratios, making it optimal for structural marine elements exposed to saltwater atmospheres. It features outstanding weldability and workability, allowing for customization in intricate fencing and railing frameworks.

Features and Benefits

| Feature | Description | Benefit |

|---|---|---|

| Corrosion Resistance | Outstanding resistance to seawater and salt spray due to magnesium content | Long-lasting durability in coastal environments |

| High Strength | Tensile strength ranging from 290 to 350 MPa depending on temper | Can withstand physical stresses and mechanical loads |

| Lightweight | Approximately 2.66 g/cm³ - lighter than steel | Ease of handling, installation without heavy machinery |

| Good Weldability | Compatible with gas and arc welding processes | Simplifies fabrication, joining for custom designs |

| Non-magnetic & Non-sparking | Safe for use in environments requiring spark-resistant materials | Safety for sensitive installations and industrial use |

| Aesthetic Appearance | Good surface finish capability and resistance to staining | Maintains attractive look over time |

Chemical Composition (% by Weight)

5083 alloy’s unique features stem from an optimized mix of elements. The composition below outlines the primary constituents influencing its marine-worthy properties:

| Element | Content Range | Role / Effect |

|---|---|---|

| Aluminum (Al) | Balance | Base metal, structural framework |

| Magnesium (Mg) | 4.0 – 4.9 | Enhances strength, corrosion resistance |

| Manganese (Mn) | 0.4 – 1.0 | Improves strength and hardness |

| Chromium (Cr) | 0.05 – 0.25 | Adds improved corrosion resistance and stability |

| Iron (Fe) | ≤ 0.4 | Impurity; kept low to maintain ductility |

| Silicon (Si) | ≤ 0.4 | Impurity; affects strength and processability |

| Copper (Cu) | ≤ 0.1 | Impacts corrosion resistance slightly |

| Zinc (Zn) | ≤ 0.25 | Minor effect on strength and corrosion |

| Titanium (Ti) | ≤ 0.15 | Grain refiner; suppression of grain growth |

Mechanical Properties of 5083 Aluminum Alloy

| Property | Typical Value (H116 / H321 Tempers) | Unit |

|---|---|---|

| Tensile Strength (UTS) | 290–350 | MPa |

| Yield Strength (0.2% PS) | 125–215 | MPa |

| Elongation (%) | >12 | % |

| Density | 2.66 | g/cm³ |

| Hardness (Brinell) | 75–85 | HB |

| Modulus of Elasticity | 70 | GPa |

Technical Specifications

| Parameter | Details |

|---|---|

| Standard Designation | Aluminum Alloy 5083 |

| Typical Tempers | O (annealed), H116, H321, etc. |

| Corrosion Resistance | Excellent against seawater, marine atmospheres |

| Welding Compatibility | TIG, MIG, Resistance Welding |

| Forming Methods | Rolling, extrusion, forging |

| Surface Finishing | Anodizing, painting, powder coating |

| Maximum Thickness | Varies, up to 100 mm for marine-grade curtain walls |

Applications of 5083 Marine aluminum fencing and railings

- Coastal Railings: Ideal for safety railings on piers, sea walls, and marinas with exposure to saltwater.

- Marine Fencing: Perimeter fencing for marine ports, boat yards, and coastal protection zones.

- Balustrades and Stairways: Long-lasting bases for external stairways and balconies near water bodies.

- Bridge Handrails: Lightweight, corrosion-resistant railing material for pedestrian and roadway bridges near coasts.

- Architectural Designs: Excellent fit for specialty architectural fencing requiring durability as well as aesthetics in high-humidity environments.

Advantages Over Alternative Materials

| Factor | 5083 Aluminum Alloy | Steel | Wood | Other Aluminum Alloys (e.g., 6061) |

|---|---|---|---|---|

| Corrosion Resistance | Excellent (marine grade) | Poor without treatments | Moderate (rot issues) | Good but less than 5083 |

| Weight | Low (2.66 g/cm³) | High (7.85 g/cm³) | Low (varies but heavier than alloy) | Comparable |

| Maintenance | Low – minimal corrosion issues | High – requires coatings | High – requires treatments | Medium |

| Strength | High tensile and yield strength | Variable; often higher | Low to moderate | Lower strength in marine |

| Aesthetic Longevity | Excellent resistant to staining/surface oxidation | Prone to rust stains | Can degrade/fade | Good but less corrosion-resistant |

Related Products

Marine aluminum fencing and railings

Marine Grade Aluminum Fencing and Railings are fabricated using marine-grade aluminum alloys such as 5083, 5052, and 6061, which are engineered specifically for protection against saltwater corrosion and marine atmospheric conditions.

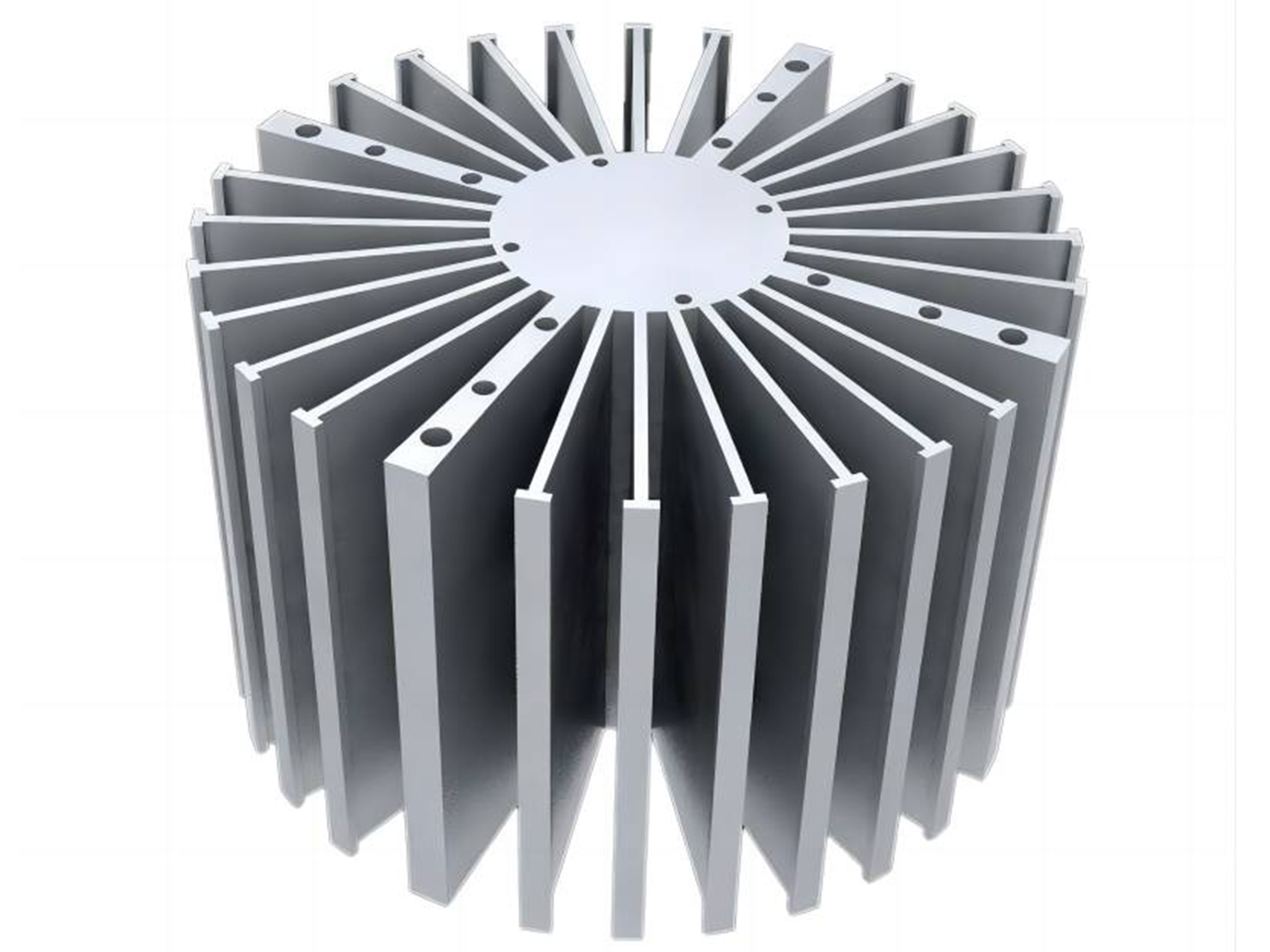

View DetailsMarine aluminum heat sink profile

Marine Grade Aluminum Heat Sink Profiles utilize alloys such as 6061 and 6063 that not only exhibit high thermal conductivity but also possess excellent corrosion resistance required for saltwater exposure.

View DetailsMarine aluminum customized shapes

Marine Grade Aluminum Customized Shapes encompass a broad range of aluminum extrusions and fabrications engineered beyond standard profiles—such as channels, angles, tubes, and beams—into complex, project-specific geometries.

View DetailsRelated Blog

5083 Marine Aluminum Customized Shapes for Custom Ship Hull Construction

In the realm of marine engineering, the construction of ship hulls strikes at the foundation of naval architecture and ship integrity. Among the variety of materials available, instead, one alloy has repeatedly distinguished itself as the go-to choice.

View Details5083 Marine Aluminum Customized Shapes for Offshore Vessel Deck Reinforcements

In the demanding environments of offshore vessels, materials used for deck reinforcements must exhibit exceptional mechanical strength, corrosion resistance, and structural reliability.

View Details5083 Marine Aluminum Customized Shapes for Coastal Infrastructure Design and Build

When it comes to the demanding environments of coastal infrastructure design and build, 5083 Marine Aluminum continues to solidify its leadership with exceptional strength and corrosion resistance.

View Details5083 Marine Aluminum Customized Shapes for Offshore Vessel Deck Frame Reinforcements

When it comes to offshore vessel deck frame reinforcements, the choice of materials is critical for durability, strength, and corrosion resistance. Among the myriad of options.

View DetailsMarine Aluminum Fencing and Railings for Durable Boat Deck Guardrails

OverviewMarine aluminum fencing and railings are purpose-designed alloy systems used for guardrails, handrails, stanchions, and safety barriers on boats, docks, marinas, and waterfront properties.

View Details5083 Marine Aluminum Customized Shapes for Saltwater Resistant Boat Deck Frames

When it comes to boat deck frames that endure the relentless challenge of saltwater environments, the choice of materials is paramount. Among all options.

View Details

Leave a Message