6061 6063 6082 o t5 t6 t651 h112 marine aluminum sheet

High-strength, corrosion-resistant 6061, 6063, and 6082 marine aluminum sheet in tempers O, T5, T6, T651, and H112, ideal for boat hulls, decks, structures, and offshore applications. Excellent weldability, lightweight performance, and stable mechanical properties for long-term use in seawater environments.

Marine-grade aluminum sheets in the 6xxx series—6061, 6063, and 6082—offer a powerful balance of strength, corrosion resistance, and workability. Combined with multiple tempers such as O, T5, T6, T651, and H112, these alloys cover everything from highly formable parts to precision-machined structural components.

They are widely used in:

- Small and medium boat hulls

- Deck structures and superstructures

- Railing systems and walkways

- Offshore platforms and marine equipment frames

- Ramps, gangways, and lightweight bridges

These alloys rely on Al-Mg-Si chemistry, which delivers good mechanical strength while maintaining excellent weldability and marine durability.

Features at a Glance

| Feature | 6061 | 6063 | 6082 |

|---|---|---|---|

| Alloy family | Al-Mg-Si (6xxx series) | Al-Mg-Si (6xxx series) | Al-Mg-Si (6xxx series, higher strength) |

| Typical marine role | Structural & machined components | Profiles, trim, light-duty structures | High-strength structural & deck plating |

| Corrosion resistance in seawater | Very good | Very good | Very good |

| Weldability | Excellent | Excellent | Excellent (requires good procedure control) |

| Formability | Good | Very good | Good to moderate (depending on temper) |

| Strength potential (T6) | Medium-high | Medium | High |

| Surface finish | Good, can be anodized | Excellent, preferred for anodizing | Good |

Available Tempers and Their Typical Use

| Temper | Condition description | Typical use in marine field |

|---|---|---|

| O | Fully annealed, softest state | Deep forming, complex bending, cold spinning, flanging |

| T5 | Cooled from forming + artificially aged | Extrusions needing moderate strength and quicker processing |

| T6 | Solution heat-treated + artificially aged | General structural parts, decks, stiffeners, brackets |

| T651 | T6 + stress-relieved by stretching | Precision-machined plates, jigs, frames, machined panels |

| H112 | Slightly strain-hardened, not fully hard | Plates for marine hulls, decks, with good formability |

Chemical Composition

Typical chemical compositions of 6061, 6063, and 6082 marine aluminum sheet (wt% range; balance Al):

| Alloy | Si | Mg | Mn | Fe | Cu | Cr | Zn | Ti | Others (each/total) |

|---|---|---|---|---|---|---|---|---|---|

| 6061 | 0.40–0.80 | 0.80–1.20 | ≤0.15 | ≤0.70 | 0.15–0.40 | 0.04–0.35 | ≤0.25 | ≤0.15 | ≤0.05 / ≤0.15 |

| 6063 | 0.20–0.60 | 0.45–0.90 | ≤0.10 | ≤0.35 | ≤0.10 | ≤0.10 | ≤0.10 | ≤0.10 | ≤0.05 / ≤0.15 |

| 6082 | 0.70–1.30 | 0.60–1.20 | 0.40–1.00 | ≤0.50 | ≤0.10 | ≤0.25 | ≤0.20 | ≤0.10 | ≤0.05 / ≤0.15 |

- The higher Mg and Mn in 6082 deliver superior strength compared with 6061 and 6063.

- The balanced Si-Mg levels enable precipitation hardening (T tempers) while retaining good weldability.

Mechanical Properties by Alloy and Temper

Typical room-temperature mechanical properties for commonly used marine tempers:

| Alloy | Temper | Thickness range (mm) | Tensile strength Rm (MPa) | Yield strength Rp0.2 (MPa) | Elongation A50 (%) |

|---|---|---|---|---|---|

| 6061 | O | 1.0–20 | 110–145 | 55–85 | 18–25 |

| 6061 | T6 | 1.0–25 | 260–310 | 240–280 | 8–12 |

| 6061 | T651 | 6.0–200 | 260–310 | 240–280 | 8–10 |

| 6063 | O | 1.0–10 | 90–130 | 40–65 | 18–25 |

| 6063 | T5 | 1.0–10 | 160–215 | 110–160 | 8–14 |

| 6063 | T6 | 1.0–10 | 190–245 | 160–210 | 8–12 |

| 6082 | O | 2.0–20 | 110–150 | 50–80 | 16–22 |

| 6082 | T6 | 2.0–80 | 290–340 | 240–300 | 8–12 |

| 6082 | H112 | 4.0–80 | 190–260 | 110–200 | 10–16 |

Values are typical and may vary slightly with thickness and product standard. For classification or certification work, always check project-specific MTCs (mill test certificates).

Dimensional Range and Tolerances

| Parameter | Typical range / capability |

|---|---|

| Thickness | About 1.0–200 mm (depending on alloy and temper) |

| Width | About 1000–2500 mm |

| Length | About 2000–12000 mm, custom cut-to-length available |

| Flatness | Marine plate flatness typically meets or exceeds EN/ASTM |

| Edge type | Mill edge or sawn edge, deburred as requested |

Marine Performance and Corrosion Behavior

| Property | Description / Benefit |

|---|---|

| Seawater corrosion resistance | Very good, especially with proper surface preparation |

| Galvanic compatibility | Good with most marine alloys; avoid direct contact with Cu-rich metals unless insulated |

| Stress-corrosion cracking | Generally low tendency in tempers suited for marine use |

| Fatigue resistance | Good for cyclic loads with proper design and weld quality |

| Anodizing response | 6063 best for architectural finish; 6061 and 6082 also suitable |

For harsh marine or splash-zone use, coating systems such as anodizing + sealing, epoxy primers, or polyurethane topcoats are recommended, especially on welded areas and cut edges.

Applications in the Marine and Offshore Industry

| Application field | Typical alloy / temper combination | reasons for use |

|---|---|---|

| Boat hull plating | 6082 H112, 6082 O, 6061 H112 | Good formability, high strength, strong weld joints |

| Decks and superstructures | 6061 T6/T651, 6082 T6 | Weight reduction, rigidity, good corrosion resistance |

| Ramps and gangways | 6082 T6, 6061 T6 | High strength, stiffness, easy fabrication |

| Railings, ladders, walkways | 6063 T5/T6, 6061 T6 | Attractive finish, anodizing, moderate strength |

| Offshore platform components | 6082 T6/T651, 6061 T651 | Stable dimensions, machinability, structural integrity |

| Cabins and interior structures | 6063 T5/T6, 6061 O/T6 | Formability, lightweight panels, good surface quality |

| Brackets & fittings | 6061 T6/T651, 6082 T6 | Machinability, strength, repeatable tolerances |

Processing, Fabrication, and Joining

| Aspect | Notes for marine fabricators |

|---|---|

| Cutting | Suitable for sawing, plasma, laser, and waterjet; minimal burrs with correct tooling |

| Forming | O and H112 tempers recommended for tight bending and deep forming |

| Welding | MIG/TIG with 5356 or 4043 filler commonly used; pre-cleaning is essential |

| Machining | Best in T6/T651; chips break well, good dimensional accuracy possible |

| Heat treatment | 6061/6082 can be solution heat-treated and aged; 6063 mainly used in T5/T6 from extrusion |

| Surface finish | Brushing, polishing, and anodizing all possible for marine aesthetic and protection |

To minimize distortion during welding, using balanced weld sequences, proper fixturing, and, for critical parts, T651 stress-relieved plates is recommended.

Comparison with Other Marine Alloys

While 5xxx series alloys (such as 5083, 5086) are classic choices for hulls, the 6xxx series offers unique advantages in many marine applications:

| Criterion | 5xxx marine alloys (e.g., 5083) | 6xxx marine alloys (6061/6063/6082) |

|---|---|---|

| Primary strengthening | Strain hardening (H tempers) | Precipitation hardening (T tempers) |

| Strength-to-weight | High in mid-hard H tempers | Wide range; 6082 T6 very competitive |

| Weld strength retention | Excellent | Very good with correct procedure, slightly lower than 5xxx in some cases |

| Machinability | Moderate | Generally better, especially in T6/T651 |

| Surface finish aesthetic | Good | Excellent, particularly 6063 |

| Dimensional stability | Good | Very good in stress-relieved temper (T651) |

For many structural, machined, or aesthetic components above the waterline, 6xxx alloys are often the most economical and technically balanced option.

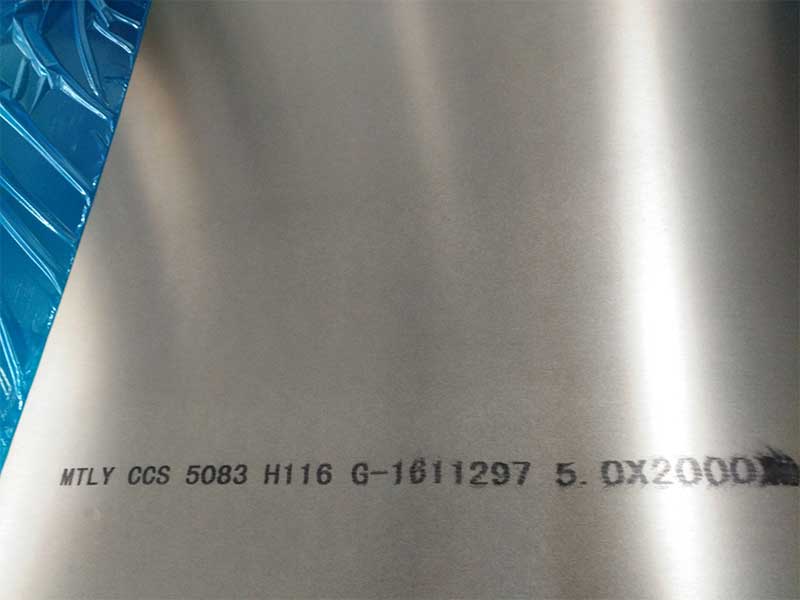

Quality Standards and Certification

| Item | Typical standards / options |

|---|---|

| Product standards | ASTM B209, EN 485, EN 573, GB/T etc. |

| Marine classification | Supply possible under DNV, ABS, LR, BV, CCS requirements |

| Inspection & testing | Mechanical testing, chemical analysis, ultrasonic testing (UT) for thick plates |

| Documentation | Mill test certificate (EN 10204 3.1 / 3.2 on request) |

Why Choose 6061, 6063, 6082 Marine Aluminum Sheet

- Wide strength range from fully annealed O to high-strength T6 and T651

- Excellent weldability and formability for complex marine structures

- Good seawater corrosion resistance, especially with appropriate coatings

- Stable dimensions and good machinability for precision components

- Flexible supply range in thickness, width, length, and temper for custom projects

For boat builders, shipyards, and offshore fabricators looking for a lightweight, strong, and versatile sheet material, 6061, 6063, and 6082 in O, T5, T6, T651, and H112 tempers deliver a reliable, proven solution across a wide spectrum of marine environments.

Related Products

Marine 5383 aluminum sheet

5383 aluminum is a strain-hardened, non-heat-treatable alloy from the 5xxx series primarily alloyed with magnesium. It exhibits a unique balance of corrosion resistance and mechanical properties particularly suited for marine applications.

View DetailsMarine 5052 aluminum sheet

Aluminum alloy 5052 is a non-heat-treatable, strain-hardened alloy with magnesium as the primary alloying element. It is designed to offer superior corrosion resistance in marine and saline environments, making it a dependable choice for components exposed directly to seawater or coastal atmospheric conditions.

View DetailsMarine 5086 aluminum sheet

This product article provides an in-depth and comprehensive understanding of Marine 5086 Aluminum Sheets, including their chemical composition, mechanical properties, corrosion resistance, fabrication capabilities, and typical marine applications.

View DetailsMarine anodized aluminum sheets

Marine Anodized Aluminum Sheets start with premium marine-grade aluminum alloys such as 5000 and 6000 series (typically 5083, 5052, and 6061).

View DetailsMarine perforated aluminum sheets

Marine Perforated Aluminum Sheets feature a series of uniform holes or shapes punched through the aluminum surface. These perforations can vary in size, pattern, and open area to tailor the sheets for specific applications.

View DetailsMarine Aluminum Tread Sheets

Marine Aluminum Tread Sheets are aluminum alloy plates featuring a raised surface pattern, commonly referred to as a tread design or diamond plate.

View DetailsRelated Blog

1060 2024 3003 6061 7075 aluminum sheet for boat

When selecting aluminum sheets for marine applications, one must consider not only the alloy's strength and weight but also its resistance to corrosion, formability, and other properties that can influence a vessel's performance and longevity.

View Details6061 6063 6082 o t5 t6 t651 h112 marine aluminum sheet

High-strength, corrosion-resistant 6061, 6063, and 6082 marine aluminum sheet in tempers O, T5, T6, T651, and H112, ideal for boat hulls, decks, structures, and offshore applications.

View DetailsAluminum sheet tai 6061 alloy metal rolls for boat

Aluminum has long been the favored material in maritime applications due to its unique combination of lightweight characteristics and exceptional resistance to corrosion.

View Details6061 5mm thick 4x8 aluminum sheet for boat

When it comes to maritime applications, selecting the right materials is crucial. Among the varied options available in the world of marine engineering, the 6061 aluminum alloy stands out especially for its versatility, durability, and performance.

View Details

Leave a Message