Aluminum sheet tai 6061 alloy metal rolls for boat

Aluminum has long been the favored material in maritime applications due to its unique combination of lightweight characteristics and exceptional resistance to corrosion. Among the various aluminum alloys available, the 6061 alloy crawls to the top, proving to be a superhero material specifically in demanding marine environments.

Aluminium 6061 Alloy

Composition and Properties

Aluminum 6061 is a versatile cadet within the broader family of aluminum alloys, primarily made up of Aluminum (90.7-94.7%), with additional elements including Silicon (0.4-0.8%) and Magnesium (0.8-1.2%). This formula yields enhanced features that render it particularly optimal for the requirements of the boating industry:

| Element | Content (%) |

|---|---|

| Aluminum | 90.7 - 94.7 |

| Silicon | 0.4 - 0.8 |

| Magnesium | 0.8 - 1.2 |

| Copper | Up to 0.4 |

| Iron | Up to 0.15 |

| Manganese | 0.15 - 0.4 |

| Zinc | Up to 0.25 |

| Titanium | Up to 0.15 |

Mechanical Properties

The aluminum alloy boasts notable mechanical properties, making it both strong and workable for structural applications:

| Property | Value |

|---|---|

| Yield Strength (MPa) | 230-300 |

| Tensile Strength (MPa) | 310-380 |

| Elongation at Break | 12% - 25% |

| Hardness (Brinell) | 60-110 (depending on temper) |

Exceptional Attributes for Marine Applications

Numerous performance aspects place 6061 aluminum ahead of other metals in boat manufacturing:

Corrosion Resistance: The presence of magnesium in the alloy facilitates the formation of a thin, protective oxide layer on its surface, significantly lessening risks of corrosion even in harsh marine environments.

Lightweight Structure: Weighing about one-third of steel, aluminum significantly reduces the overall weight—and consequently, the fuel consumed during travel—manifests clear advantages over heavier materials.

High Weldability and Workability: The versatility of 6061 accommodates complex marine constructs effortlessly. Its properties allow for intricate shapes that can be achieved via ease of machining and mMultiplemake capdging, lending to smart design without sacrificing strength.

Tempering Conditions and Heat Treatment

Aluminum 6061 can be modified in various tempering conditions, notably extruded shapes or items usually transformed through heat treatment to optimize performance. For instance:

- T4: Solution heat-treated and artificially aged to enhance better resistance; ideal for applications where medium strength is fine.

- T6: Artfully aged to higher pressure points renders remarkable tensile correction, contributing the higher strength appealed for thick-section panels or structural beam products and components highly favored in boats.

Applications of Aluminum 6061 Rolls in the Marine Domain

Given its enduring legacy and technical specifications, the 6061 Aluminum alloy shear and rolls often apply transnationally in various aluminum sheets utilized in boat manufacturing:

- Hulls and Skins: Crafted into robust paneling in boat manufacture providing a shield against marine forces.

- Exterior Architecture: Custom facias, railings, and mounts capitalize on the scratch and cut resistant properties of aluminum instead of rust-prone defaults.

- Upperworks and Fixed Installations: Used as integral backing elements delivering anchorage to a variety of attached gear both aesthetic and functional.

Implementation Standards

Aluminum 6061 sheet relies heavily on adherence to a series of definable standards to ensure safety and security encompass government-regulated construction principles while achieving consistent quality:

- ASTM B221: This standard outlines mechanical testing requirements, which offer specified resistance designed purposes.

- MIL-DTL-46027: Stipulates parameters for delivered structural, non-reinforced plates ordered from abroad for naval engineering.

Related Products

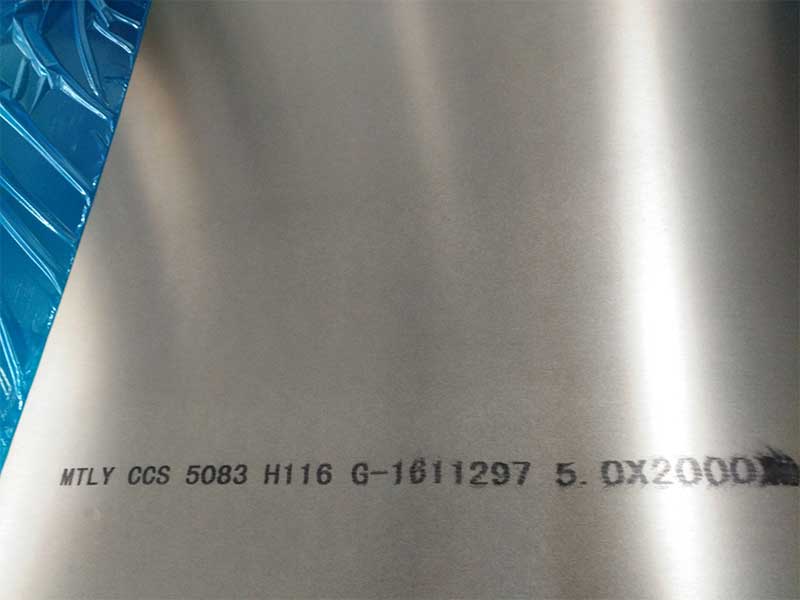

Marine 5083 aluminum sheet

Aluminum alloy 5083 is a non-heat-treatable alloy primarily composed of magnesium and trace elements that deliver outstanding protection against corrosion, particularly in seawater and saline atmospheres.

View DetailsMarine perforated aluminum sheets

Marine Perforated Aluminum Sheets feature a series of uniform holes or shapes punched through the aluminum surface. These perforations can vary in size, pattern, and open area to tailor the sheets for specific applications.

View DetailsMarine 5052 aluminum sheet

Aluminum alloy 5052 is a non-heat-treatable, strain-hardened alloy with magnesium as the primary alloying element. It is designed to offer superior corrosion resistance in marine and saline environments, making it a dependable choice for components exposed directly to seawater or coastal atmospheric conditions.

View DetailsMarine 5086 aluminum sheet

This product article provides an in-depth and comprehensive understanding of Marine 5086 Aluminum Sheets, including their chemical composition, mechanical properties, corrosion resistance, fabrication capabilities, and typical marine applications.

View DetailsMarine Aluminum Tread Sheets

Marine Aluminum Tread Sheets are aluminum alloy plates featuring a raised surface pattern, commonly referred to as a tread design or diamond plate.

View DetailsMarine anodized aluminum sheets

Marine Anodized Aluminum Sheets start with premium marine-grade aluminum alloys such as 5000 and 6000 series (typically 5083, 5052, and 6061).

View DetailsRelated Blog

Aluminum sheet tai 6061 alloy metal rolls for boat

Aluminum has long been the favored material in maritime applications due to its unique combination of lightweight characteristics and exceptional resistance to corrosion.

View Details

Leave a Message