6061 T6 marine aluminum flat bar

6061 T6 marine aluminum flat bar is a widely used structural and fabrication material within the marine industry. Combining excellent strength, good corrosion resistance, weldability, and formability, 6061-T6 flat bars offer reliable performance in saltwater and coastal environments where weight savings, durability, and ease of fabrication are important.

features

- Good strength-to-weight ratio: T6 temper (solution heat-treated and artificially aged) delivers robust mechanical properties suitable for structural components.

- Excellent corrosion resistance in marine atmospheres: naturally forms a protective alumina film and performs well in coastal and mildly aggressive saltwater exposures.

- Good weldability and brazability: common welding methods (TIG, MIG, resistance) produce sound joints when proper procedures are used.

- Good machinability and formability: suitable for routing, drilling, milling, bending and punching; however, some springback can occur and recommended bend radii should be observed.

- Non-magnetic and electrically conductive: useful for applications where magnetism must be avoided.

- Lightweight: substantially lower density than steel (≈ 2.70 g/cm³), enabling weight savings for marine and transport applications.

- Available in multiple surface finishes: mill finish, anodized, painted or bead-blasted for aesthetic and protective needs.

Chemical composition (typical limits) — 6061 alloy

| Element | Typical range (wt%) |

|---|---|

| Silicon (Si) | 0.4–0.8 |

| Iron (Fe) | ≤0.7 |

| Copper (Cu) | 0.15–0.40 |

| Manganese (Mn) | ≤0.15 |

| Magnesium (Mg) | 0.8–1.2 |

| Chromium (Cr) | 0.04–0.35 |

| Zinc (Zn) | ≤0.25 |

| Titanium (Ti) | ≤0.15 |

| Others (each) | ≤0.05 |

| Aluminum (Al) | Balance (≈97.9–99.0) |

Note: Composition limits follow common specifications (for example, ASTM B209/B221 and AMS/EN equivalents). Consult mill test certificates or applicable standards for precise tolerances per order.

Mechanical properties — 6061 T6 (typical)

| Property | Typical value |

|---|---|

| Tensile strength (ultimate) | 290–310 MPa (42–45 ksi) |

| Yield strength (0.2% offset) | 240–255 MPa (35–37 ksi) |

| Elongation (in 50 mm) | 8–12% |

| Brinell hardness (HB) | ~95–120 |

| Modulus of elasticity | ~69 GPa (10,000 ksi) |

| Density | 2.70 g/cm³ (0.0975 lb/in³) |

Values are indicative; exact values depend on product form, temper, thickness, and supplier processing.

Common sizes and tolerances

6061 T6 aluminum flat bars are produced in a wide range of widths and thicknesses. Typical stock sizes include:

- Thickness: 1.5 mm up to 50 mm (commonly 2–25 mm for many applications)

- Width: 10 mm up to 300 mm (commonly 12–200 mm)

- Length: standard mill lengths 1000–6100 mm (1–6.1 m) or cut-to-length per customer requirement

Tolerances typically follow standards such as ASTM B221 or EN 573/755 for extruded shapes. Tolerances vary by thickness and width; consult supplier catalogs for exact machining and extrusion tolerances.

Surface finishes

- Mill finish: as-extruded or as-rolled surface; economical and used for structural or concealed components.

- Brushed/bead-blasted: improves appearance and can slightly improve surface corrosion behavior.

- Anodized: decorative and protective. Enhances corrosion resistance and wear properties; available in clear or colored anodizing (typical anodic film thickness 5–25 µm).

- Painted or powder-coated: used when color matching or additional protection is required; priming recommended for marine exposures.

- Polished: for aesthetic components such as railings and trim.

Fabrication and joining

- Welding: 6061-T6 is weldable by MIG (GMAW), TIG (GTAW), and resistance methods. Note: the HAZ (heat-affected zone) softens; post-weld heat treatment or local reinforcement may be required if strength must be fully restored. Filler alloys such as 5356 or 4043 are commonly used depending on required properties and corrosion performance.

- Machining: good machinability; use sharp tooling and rigid setup. Take into account chip control and speeds; lubrication/coolant recommended.

- Bending/forming: possible in T6 but springback and cracking risk increase with tighter radii; consider annealing to O temper (forming) followed by re-aging if high strength is required.

- Fastening: compatible with standard mechanical fasteners; stainless steel fasteners (AISI 316) or aluminum fasteners are recommended for marine exposures to minimize galvanic corrosion. Use insulating washers or coatings where dissimilar metals contact.

- Surface treatments: anodizing, conversion coatings, and paints are commonly applied for enhanced corrosion protection.

Corrosion behavior in marine environments

- 6061 alloy forms a thin, adherent aluminum oxide layer that offers general corrosion resistance; in atmospheric marine environments this provides good service life for many structural parts.

- Pitting resistance is good in typical marine atmospheres, but in continuous immersion in aggressive seawater or in crevices, localized corrosion or galvanic corrosion can occur.

- To maximize life in marine use:

- Avoid trapping saltwater in crevices and joints.

- Use cathodic/anodic isolation when joining to more noble metals (e.g., stainless steel) using dielectric barriers.

- Prefer 5356 filler for welding in marine applications due to better corrosion resistance compared with 4043 in some cases.

- Apply protective coatings (anodize, paint) in highly aggressive or splash/immersion zones.

- Design for drainage and ventilation to minimize prolonged wetting.

Typical marine applications

- Structural components: stringers, frames, supports and brackets where lightweight strength is needed.

- Deck fittings and trim: cleats, chocks, non-structural trim pieces, and decorative rails.

- Rails and stanchions: sparing weight and resisting atmospheric corrosion.

- Boatbuilding: small craft hull stiffeners, internal framing, and superstructure elements.

- Platforms and gangways: lightweight platforms and access gratings where corrosion resistance and weight savings are beneficial.

- Marine fabrication projects: custom brackets, mounting plates, and assemblies where weldability and machineability are valuable.

Design considerations and best practices

- Specify the correct temper: T6 offers higher strength but reduced ductility vs. O temper. If heavy forming is needed, consider forming in O temper then precipitation harden to T6 where possible.

- Thickness and corrosion allowance: account for potential material loss in aggressive environments; use protective finish when necessary.

- Fastener selection and isolation: avoid direct contact with copper alloys or carbon steel without isolation; stainless fasteners with insulating washers are common.

- Welding procedures: use qualified welding procedures and appropriate filler metals; understand that welded T6 parts will have softened HAZ and may need design compensation.

- Inspection and maintenance: periodic visual inspections, especially of welds, joints, and coated surfaces, will extend service life in marine exposures.

Standards and specifications

Common standards covering 6061 and aluminum flat products include:

- ASTM B221 — Standard Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes

- ASTM B209 — Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate

- AMS and EN equivalents for chemical composition and mechanical properties

- ISO and marine-specific standards for coatings and fasteners

Always confirm specific standard references and mill test certificates at time of purchase.

Ordering information and customization

When ordering 6061 T6 marine aluminum flat bar, provide:

- Alloy and temper (6061-T6)

- Exact dimensions (thickness × width × length)

- Surface finish (mill, anodized, painted)

- Quantity and length tolerances (cut-to-length vs. full mill length)

- Certification requirements (MTC, chemical and mechanical test reports)

- Any special fabrication (pre-drilled holes, cutouts, pre-anodized, formed parts)

Suppliers may offer custom extrusions, pre-machining, or fabrication services such as welding and anodizing.

6061 T6 marine aluminum flat bar is a versatile, high-performance material well suited for many marine applications requiring strength, corrosion resistance, and lightweight construction. Proper selection of temper, protective finishes, welding and fastening practices, and sound design to avoid crevices and dissimilar metal contact will ensure long-term, reliable service in marine and coastal environments.

For specific project requirements or to request quotes for custom sizes, finishes, or certification, contact your aluminum supplier with the alloy/temper, dimensions, quantities, and any applicable standards you require.

Related Products

6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

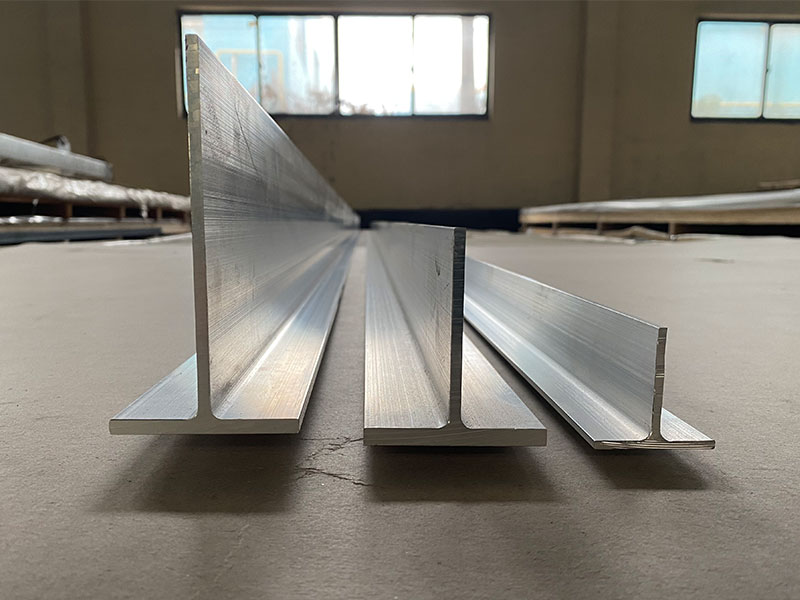

View DetailsMarine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View DetailsMarine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View DetailsMarine aluminum I-beams

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction.

View Details5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View DetailsMarine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View DetailsRelated Blog

6061 Marine Aluminum Z Shaped Sections for Marine Frame Customization

In the marine industry's relentless quest for durability, corrosion resistance, and structural integrity, 6061 Marine Aluminum stands out as a premier choice—especially when customized in Z shaped sections for marine frameworks.

View Details6061 Marine Aluminum Channels for High Strength Coastal Engineering

Marine aluminum has revolutionized coastal engineering, and at the fulcrum of this evolution lies 6061 marine aluminum channels. These channels bring unparalleled strength, corrosion resistance.

View Details6061 Marine Aluminum Round Bar for Heavy Duty Marine Frame Reinforcements

6061 Marine Aluminum Round Bar is a premium-grade aluminum product specifically engineered for heavy-duty marine frame reinforcements. Renowned for its superior strength, corrosion resistance, and excellent machinability.

View Details6061 T6 Marine Aluminum Flat Bar for Heavy Duty Boat Frame Parts

Strength, corrosion resistance, and durability of 6061 T6 Marine Aluminum Flat Bar – the ideal choice for heavy duty boat frame components ensuring longevity and performance in harsh marine environments.

View Details6061 Marine Aluminum Round Bar for Lightweight Coastal Shipbuilding

Superior strength, corrosion resistance, and versatility of 6061 marine aluminum round bars, expertly crafted for lightweight coastal shipbuilding applications. Explore detailed specifications, tempering options, and chemical properties tailored for marit

View Details6061 T6 marine aluminum flat bar

6061 T6 marine aluminum flat bar is a widely used structural and fabrication material within the marine industry. Combining excellent strength, good corrosion resistance, weldability, and formability.

View Details

Leave a Message