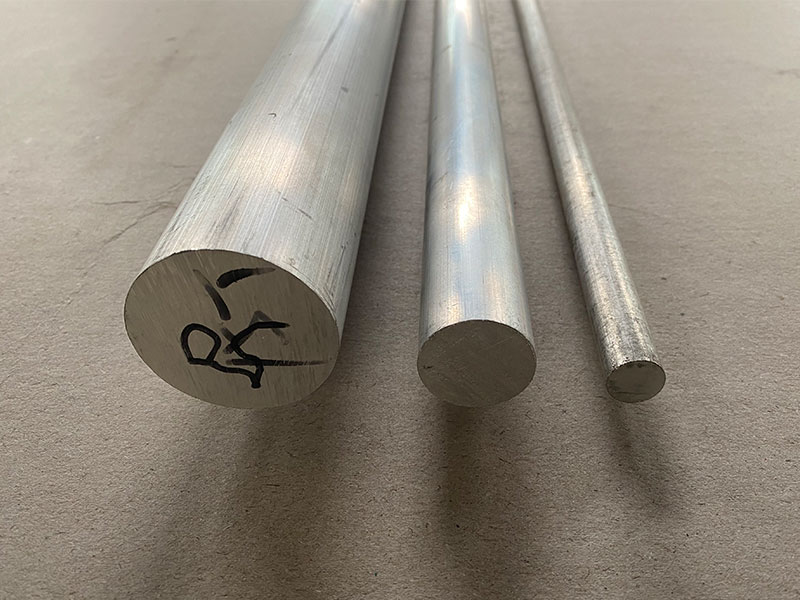

6082 Marine Aluminum Bar for Custom Boat Fabrication and Reinforcement

When it comes to custom boat fabrication and structural reinforcement in marine environments, material choice is paramount. The 6082 Marine Aluminum Bar stands out as a superior solution that combines strength, corrosion resistance, and workability — ideal for maritime applications demanding both durability and precision.

What is 6082 Marine Aluminum?

6082 aluminum is a medium-strength alloy rich in magnesium and silicon, belonging to the 6XXX series. Its balanced mechanical properties and excellent corrosion resistance make it a highly sought-after material across marine, structural, and general engineering fields. The "Marine" grade signifies additional processing or surface finishing that augments its corrosion resistance traits specifically for harsh saltwater environments.

Detailed Chemical Composition of 6082 Aluminum Alloy

| Element | Percentage (%) |

|---|---|

| Magnesium (Mg) | 0.6 – 1.2 |

| Silicon (Si) | 0.7 – 1.3 |

| Manganese (Mn) | 0.4 – 1.0 |

| Iron (Fe) | ≤ 0.5 |

| Copper (Cu) | ≤ 0.1 |

| Chromium (Cr) | ≤ 0.25 |

| Zinc (Zn) | ≤ 0.2 |

| Titanium (Ti) | ≤ 0.1 |

| Residuals | ≤ 0.15 |

| Aluminum (Al) | Balance (~95.5 – 98.4) |

Mechanical Properties

| Property | Value | Test Standard |

|---|---|---|

| Ultimate Tensile Strength | 280 – 310 MPa | ASTM B209 |

| Yield Strength (0.2% offset) | 240 – 260 MPa | ASTM B209 |

| Elongation at Break | 8 – 12% | ASTM E8 |

| Hardness (Brinell) | 95 HB | ASTM E10 |

| Density | 2.70 g/cm³ | |

| Thermal Conductivity | 180 W/(m·K) | |

| Melting Point | 582 – 652 °C |

Features of 6082 Marine Aluminum Bar

Excellent Corrosion Resistance: With the presence of magnesium and silicon alloys, 6082 shows outstanding resistance to seawater corrosion, eliminating the risk of pitting and stress corrosion cracking, common challenges in the marine environment.

High Strength-to-Weight Ratio: Ideal for custom boat fabrication, this aluminum alloy provides structural integrity and durability with significantly less weight than steel, contributing to damper fuel consumption and enhanced vessel agility.

Good Weldability: 6082 maintains structural strength after welding without extensive post-weld heat treatments, facilitating custom joints, reinforcements, and fabrications on marine vessels.

Machinability: Aside from fabrication, 6082 is easily machinable making post-processing for components like brackets, frames, and rails efficient and precise.

Surface Finish: Smooth and aesthetically pleasing surface ready for anodization or other protective coatings suitable for marine environments.

Applications in Custom Boat Fabrication and Reinforcement

1. Structural Elements

Frames and Ribs:The 6082 bar is predominantly used for boat frames and ribs enabling robust skeleton construction that supports hull integrity and load distribution.

Stringers and Longitudinal Beams:Acts as reinforcement in stringers enhancing hull rigidity without adding undue weight.

2. Deck and Superstructure Components

Custom deck fittings, handrails, mounts, and reinforcements exploit 6082’s corrosion resistance and light weight to offer durability — while facilitating easy machining into complex profiles as required by bespoke designs.

3. Custom Marine Hardware

Brackets, mounting plates, cleats, and other mechanical hardware fabricated from 6082 bars ensure longevity and operate reliably in continuous exposure to seawater and mechanical stress.

4. Repairs and Retrofit Reinforcement

The versatility of 6082 Marine Aluminum Bars allows them to be substituted in retrofit applications or hull damage repairs, restoring vessel strength and preventing further corrosion or fatigue issues.

Why Choose 6082 Aluminum Bars Over Other Materials?

| Factor | 6082 Aluminum Bar | Alternatives (Steel & Other Alloys) |

|---|---|---|

| Weight | Lightweight – density 2.70 g/cm³ | Heavier – steel ~ 7.85 g/cm³ |

| Corrosion Resistance | Excellent for marine environments | Steel prone to rust and requires coating; other alloys may corrode more |

| Strength | High strength suitable for structural demands | High for steel but heavier |

| Fabrication | Excellent weldability and machinability | Some alloys require heat treatment and welding complexities |

| Maintenance | Low maintenance due to natural oxide surface protection | Requires constant maintenance/coatings |

| Cost | Competitive price for performance offered | Variable, often higher lifecycle cost |

Standard Sizes and Finishes Available

| Dimension (mm) | Tolerance | Typical Condition | Surface Finish |

|---|---|---|---|

| Diameter: 8 – 200 | ±0.05 – 0.5 mm | T6, T651, or Annealed | Mill Finish / Anodized |

| Rectangular Bar | Custom cut lengths up to 6 meters | Same as above | Mill Finish / Polished |

Related Products

Marine aluminum hexagonal bars

Marine Grade Aluminum Hexagonal Bars are produced from premium corrosion-resistant aluminum alloys such as 5083, 5052, 6061, and 6082.

View Details6082 marine aluminum rod & bar

6082 Aluminum Rods & Bars are extruded or rolled products manufactured from 6082 aluminum alloy — a thermally treated (typically T6 temper) aluminum-magnesium-silicon alloy that balances high tensile strength, good weldability, and excellent corrosion resistance.

View DetailsMarine grade aluminum solid bar

Marine Grade Aluminum Solid Bars are produced from premium aluminum alloys optimized for saltwater exposure, such as 5083, 5052, 6061, and 6082. These alloys offer unparalleled resistance to corrosion caused by seawater, salt spray, and marine atmospheres, while maintaining excellent mechanical strength and toughness.

View DetailsMarine aluminum hollow bars

Marine Grade Aluminum Hollow Bars are fabricated from high-quality alloys such as 5083, 5052, 6061, and 6082, all known for their exceptional resistance to seawater corrosion, salt spray, and marine atmospheres.

View DetailsRelated Blog

6082 Marine Aluminum Bar for High Strength Marine Components

In the demanding world of marine engineering, the choice of materials defines not only the longevity but also the safety and performance of vessels. Among the plethora of metal options.

View Details6082 Marine Grade Aluminum Solid Bar for Boat Deck Reinforcements

When it comes to marine vessel construction and refurbishment, selecting the right materials is vital for ensuring durability, performance, and safety. Among various options.

View Details6082 Marine Aluminum Hexagonal Bars for Offshore Marine Construction Parts

6082 Marine Aluminum Hexagonal Bars for Offshore Marine Construction Parts: Unveiling Their Functional Excellence and Unique ApplicationsWhen it comes to the demanding realm of offshore marine construction, material selection is to ensuring longevity, saf

View Details6082 Marine Aluminum Bar for Custom Boat Fabrication and Reinforcement

When it comes to custom boat fabrication and structural reinforcement in marine environments, material choice is paramount. The 6082 Marine Aluminum Bar stands out as a superior solution that combines strength, corrosion resistance.

View Details

Leave a Message