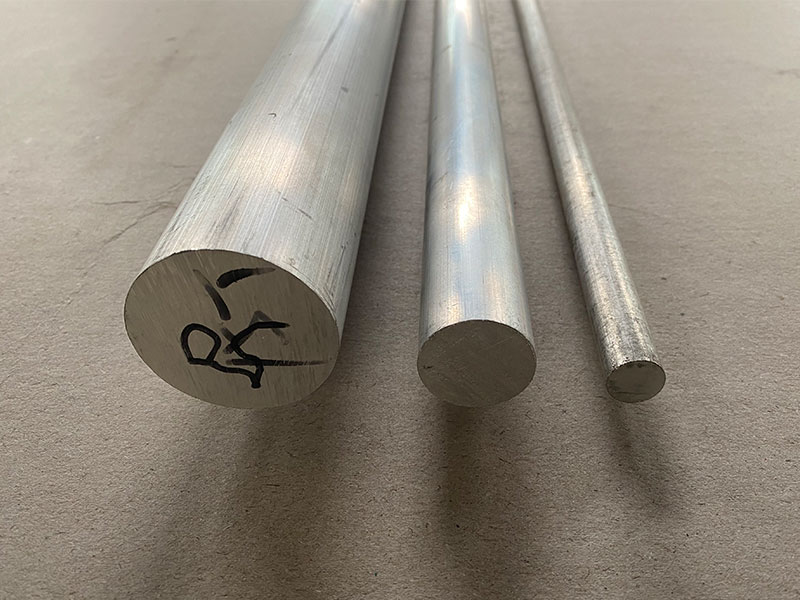

6082 Marine Grade Aluminum Solid Bar for Boat Deck Reinforcements

When it comes to marine vessel construction and refurbishment, selecting the right materials is vital for ensuring durability, performance, and safety. Among various options, 6082 marine grade aluminum solid bar stands out as a superior material for boat deck reinforcements due to its exceptional strength, corrosion resistance, and excellent machinability.

In t

6082 Aluminum Alloy: Composition and Properties

6082 aluminum belongs to the 6xxx series of aluminum alloys, characterized by silicon (Si) and magnesium (Mg) as main alloying elements. This combination gives the alloy a unique blend of moderate-to-high strength and good corrosion resistance, specifically suited for marine environments.

Chemical Composition of 6082 Alloy (Typical % Weight):

| Element | Composition (%) |

|---|---|

| Aluminum (Al) | Balance (~ 95.2 to 97.8) |

| Silicon (Si) | 0.7–1.3 |

| Magnesium (Mg) | 0.6–1.2 |

| Iron (Fe) | ≤ 0.5 |

| Manganese (Mn) | 0.4–1.0 |

| Chromium (Cr) | 0.25 |

| Copper (Cu) | ≤ 0.10 |

| Zinc (Zn) | ≤ 0.20 |

| Titanium (Ti) | ≤ 0.10 |

Alloy Tempering and Mechanical Parameters

6082 marine grade aluminum solid bars are typically supplied in T6 temper, which means the alloy has been solution heat-treated and artificially aged. This temper enhances mechanical strength and ensures dimensional stability, critical for reinforcing boat decks exposed to operational stresses.

| Parameter | Value |

|---|---|

| Ultimate Tensile Strength (Rm) | 290 – 310 MPa |

| Yield Strength (Rp0.2) | 240 – 260 MPa |

| Elongation at Break (%) | 10 – 14 |

| Density | 2.70 g/cm³ |

| Modulus of Elasticity | 69 GPa |

Superior Corrosion Resistance for Marine Use

In marine applications, structural materials must withstand constant exposure to saltwater, humidity, and UV. 6082 aluminum bars naturally form a protective oxide layer that blocks corrosion penetration. This attribute reduces maintenance costs and protects boat deck structures from long-term material degradation.

6061 and 6063 are also used aluminum marine grades, but compared to them, 6082 alloys offer enhanced strength—making it particularly suitable for critical reinforcements that face fluctuating mechanical loads.

Functions of 6082 Aluminum Solid Bars in Deck Reinforcement

- Load Distribution: The 6082 solid bar acts as a reinforcement beam or stiffener improving global deck stiffness and ability to spread applied loads efficiently.

- Structural Integrity: Reinforced deck areas provide better impact resistance against operational stresses—whether due to heavy cargo, mechanical antenna mounts, or collision.

- Weight Efficiency: With high strength-to-weight ratio, these bars support providing strength without excessive weight penalties, critical for performance and fuel efficiency.

- Ease of Fabrication: Machinability is excellent with this alloy, meaning dock engineers and workers can cut, drill, and join component parts on-site or during prefabrication quickly.

Implementation Standards and Quality Control

Dock refitting and new boat constructions using 6082 aluminum bars comply with:

- ISO 11984: Specifies aluminum alloys for marine applications.

- ASTM B221: Standard Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes.

- CCS / DNV / ABS Level Certifications for marine structural materials.

Manufacturers strictly adhere to standardized chemical and mechanical testing—such as spectrometry for composition and tensile testing per ASTM E8/E8M.

Practical Integration Examples

- Reinforcing flat deck panels preventing flex or bowing under traffic and weather.

- Frames and cross beams embedded beneath the deck joint structures adding overall longitudinal strength.

- Custom extrusions cut into task-specific sizes for rail mounts or attachments necessitating high structural load capacity.

Crafting with 6082 aluminum marine bars, vessel engineers proactively extend the service life and operational safety of the boat deck, which is frequently subjected to punishing marine conditions.

Related Products

Marine aluminum hexagonal bars

Marine Grade Aluminum Hexagonal Bars are produced from premium corrosion-resistant aluminum alloys such as 5083, 5052, 6061, and 6082.

View Details6082 marine aluminum rod & bar

6082 Aluminum Rods & Bars are extruded or rolled products manufactured from 6082 aluminum alloy — a thermally treated (typically T6 temper) aluminum-magnesium-silicon alloy that balances high tensile strength, good weldability, and excellent corrosion resistance.

View DetailsMarine aluminum hollow bars

Marine Grade Aluminum Hollow Bars are fabricated from high-quality alloys such as 5083, 5052, 6061, and 6082, all known for their exceptional resistance to seawater corrosion, salt spray, and marine atmospheres.

View DetailsMarine grade aluminum solid bar

Marine Grade Aluminum Solid Bars are produced from premium aluminum alloys optimized for saltwater exposure, such as 5083, 5052, 6061, and 6082. These alloys offer unparalleled resistance to corrosion caused by seawater, salt spray, and marine atmospheres, while maintaining excellent mechanical strength and toughness.

View DetailsRelated Blog

6082 Marine Grade Aluminum Solid Bar for Boat Deck Reinforcements

When it comes to marine vessel construction and refurbishment, selecting the right materials is vital for ensuring durability, performance, and safety. Among various options.

View Details6082 Marine Aluminum Bar for Custom Boat Fabrication and Reinforcement

When it comes to custom boat fabrication and structural reinforcement in marine environments, material choice is paramount. The 6082 Marine Aluminum Bar stands out as a superior solution that combines strength, corrosion resistance.

View Details6082 Marine Aluminum Hexagonal Bars for Offshore Marine Construction Parts

6082 Marine Aluminum Hexagonal Bars for Offshore Marine Construction Parts: Unveiling Their Functional Excellence and Unique ApplicationsWhen it comes to the demanding realm of offshore marine construction, material selection is to ensuring longevity, saf

View Details6082 Marine Aluminum Bar for High Strength Marine Components

In the demanding world of marine engineering, the choice of materials defines not only the longevity but also the safety and performance of vessels. Among the plethora of metal options.

View Details

Leave a Message