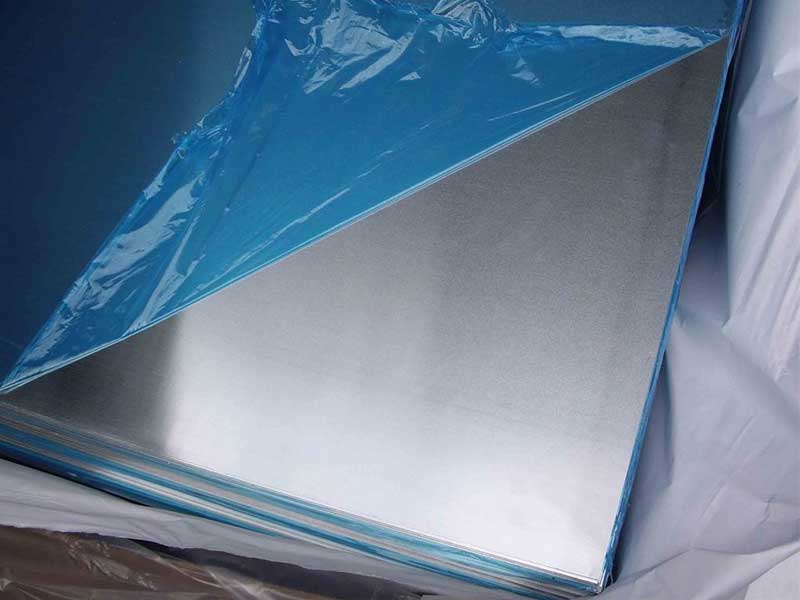

Marine Grade Aluminum Plate 5083

When it comes to building robust, durable, and corrosion-resistant marine vessels and offshore structures, Marine Grade Aluminum Plate 5083 stands as a premier choice in the industry. Far beyond just a metal sheet, this aluminum alloy offers a unique combination of strength, formability, and unmatched resistance to harsh sea environments.

What Makes 5083 a True Marine Grade Aluminum?

Marine environments demand materials that can withstand continuous exposure to seawater, salt sprays, and mechanical stresses. Aluminum alloy 5083 is a highly regarded aluminum-magnesium alloy specifically engineered to deliver superior corrosion resistance and mechanical performance in such conditions.

Attributes:

Exceptional Corrosion Resistance:The relatively high magnesium content (4.0–4.9%) combined with trace amounts of manganese and chromium yields excellent resistance against seawater, including oxide and stress corrosion cracking resistance.

Superior Strength:Its tensile strength typically ranges from 275 to 350 MPa, depending on temper, enabling structural reliability even in demanding mechanical applications.

Enhanced Weldability and Formability:Through specific tempering processes, 5083 provides excellent weldability without loss of strength, crucial for complex marine assemblies and repairs.

Implementation Standards and Alloy Tempering

Manufacturing and quality control of 5083 aluminum comply with authoritative standards ensuring consistent properties:

| Standard | Scope |

|---|---|

| ASTM B928 | Specification for Aluminum-Alloy 5083 Sheet and Plate |

| EN 485-2 | Aluminium and Aluminium Alloys – Sheet, Strip, and Plate — Mechanical Properties |

| BS EN 14142 | Shipbuilding Aluminum Alloy List |

To optimize mechanical characteristics and marine suitability, 5083 plates typically undergo specific temper conditions such as:

- H116 – Strain-hardened, then strain hardened and partially annealed, preserving good corrosion resistance, especially for welded structures exposed to marine conditions.

- H321 – Strain hardened and stabilized: enhanced with stabilization annealing for increased ductility and corrosion performance.

- O – Annealed: maximum formability but with slightly reduced strength.

Choice of temper conditions balances hardenability with the need for corrosion resistance and weld-ability based on application-specific demands.

Chemical Composition of Marine Grade Aluminum 5083

its chemical makeup is essential to appreciate its performance in corrosive environments. Typical chemical composition percentages are as follows:

| Element | Percentage (%) |

|---|---|

| Magnesium (Mg) | 4.0 – 4.9 |

| Manganese (Mn) | 0.4 – 1.0 |

| Chromium (Cr) | 0.05 – 0.25 |

| Iron (Fe) | ≤ 0.4 |

| Silicon (Si) | ≤ 0.4 |

| Copper (Cu) | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 |

| Aluminum (Al) | Remainder |

The elevated magnesium content bolsters the alloy’s marine suitability by enhancing its electrochemical stability in saltwater environments. Trace chromium helps improve resistance to pitting and intergranular corrosion.

Functions and Applications of Aluminum 5083 Marine Plates

Marine-grade 5083 aluminum serves a broad scope of essential functions in maritime industries:

1. Shipbuilding:Used extensively for hull plates, superstructures, and bulkheads. Lightweight 5083 strips reduce displacement and fuel consumption while withstanding wave impacts and corrosion.

2. Offshore Platforms:Structurally significant in oil rigs and offshore wind turbines, its excellent fatigue resistance ensures longevity against cyclic stresses under marine exposure.

3. Naval Craft:Preferred for patrol boats and military vessels requiring high strength combined with stealth and speed, as well as resistance to harsh operational seawater hazards.

4. Marine Containers and Tanks:Non-corrosive storage and transport tanks for saltwater appliances and chemicals leverage the minimal permeation and durable surface characteristics of 5083.

5. Underwater Piping and Pressure Vessels:For exposure to saline fluids and mechanical load, its integrity and weld-ability provide benefits that extend asset lifespans.

These applications confidently exploit the alloy’s characteristic durability and environmental resistance offering designers robust material selection.

Mechanical Properties (Typical Values)

| Property | Value |

|---|---|

| Tensile Strength | 290 – 350 MPa |

| Yield Strength | 125 – 215 MPa |

| Elongation at Break | ≥12% |

| Density | 2.66 g/cm³ |

| Hardness (Brinell) | 75 – 95 HB |

| Modulus of Elasticity | 70 GPa |

Related Products

Marine 5052 aluminum plate

Marine 5052 Aluminum Plate is noted for its exceptional resistance to corrosion caused by seawater, salt spray, and marine atmospheres.

View DetailsMarine 5059 aluminum plate

Marine 5059 Aluminum Plate is distinguished by its high magnesium content and carefully balanced alloying elements, designed to maximize strength without compromising corrosion resistance.

View DetailsMarine aluminum steel clad plate

Aluminum / Steel Clad Plates consist of a sandwich construction in which a layer of marine-grade aluminum alloy is metallurgically bonded to a steel substrate.

View DetailsMarine 5086 aluminum plate

5086 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys. Its hallmark is a high magnesium content—generally between 4.0% and 4.9%—which delivers enhanced corrosion resistance, particularly against saltwater and marine atmospheric conditions.

View DetailsMarine 5383 aluminum plate

The 5383 aluminum alloy belongs to the 5xxx series of aluminum-magnesium alloys known for remarkable resistance to marine corrosion and high strength.

View DetailsMarine 5083 aluminum plate

Marine 5083 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys and is classified as a non-heat-treatable alloy. Its high magnesium content (typically 4.0–4.9%) enhances its corrosion resistance, especially against seawater-related degradation such as pitting and stress corrosion cracking.

View DetailsRelated Blog

Marine 5083 5086 H116 Checkered Aluminum Plate for Deck Board

Premium Marine 5083/5086 H116 Checkered Aluminum Plate designed for deck boards. Boasting exceptional corrosion resistance, high strength, and durability, it meets marine industry standards for optimal performance in harsh sea environments.

View DetailsAluminum Alloy Plate 5083 H24 for Marine

OverviewAluminum Alloy Plate 5083 H24 is a high-performance material widely favored in marine engineering due to its excellent combination of high strength, exceptional corrosion resistance, and good weldability.

View Details3mm 5083 Marine Grade Aluminum Plate For Ship building

In the demanding world of shipbuilding, materials that combine strength, durability, and corrosion resistance are essential to construct vessels that can withstand harsh marine environments.

View DetailsMarine Grade Aluminum Plate 5083

When it comes to building robust, durable, and corrosion-resistant marine vessels and offshore structures, Marine Grade Aluminum Plate 5083 stands as a premier choice in the industry.

View DetailsMarine Grade Aluminum Alloy Plate 5083 H111 H112

When we think of maritime applications, the materials we choose are of utmost importance, and few fulfill the criteria for durability, resistance, and lightweight characteristics better than Marine Grade Aluminum Alloy 5083 H111 and H112.

View DetailsMarine Grade Plate Aluminum Sheet 5083 O H116

When it comes to marine construction and offshore applications, selecting the right material is crucial. Marine Grade Aluminum Plate 5083 O H116 stands out as a top-tier solution, blending excellent mechanical properties, corrosion resistance.

View Details

Leave a Message