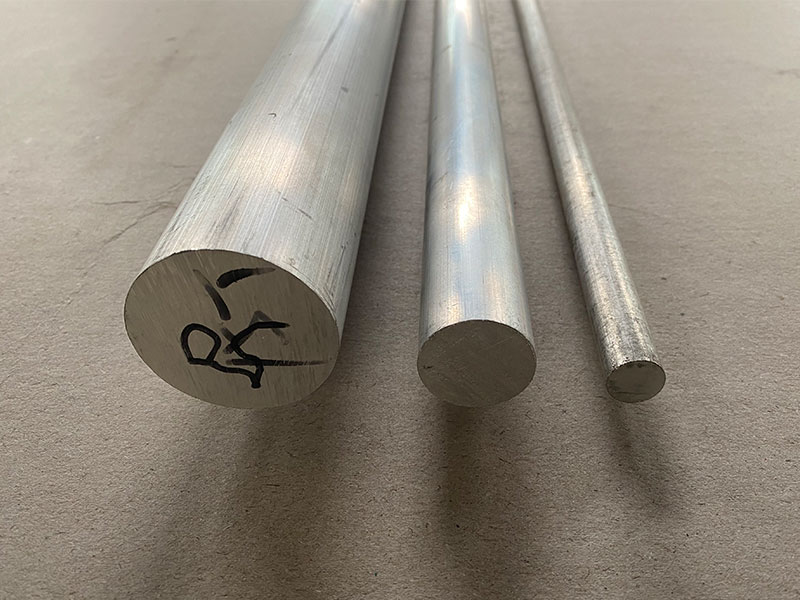

6082 Marine Aluminum Bar for Industrial Marine Design and Construction

The 6082 marine aluminum bar is a medium‑strength, heat‑treatable wrought alloy designed for demanding marine and offshore environments. Combining good corrosion resistance, excellent machining performance, and reliable weldability, it is widely used in shipbuilding, offshore structures, deck equipment, and high‑load marine components.

1. Features at a Glance

- Alloy type: 6xxx series (Al–Mg–Si)

- Strength: Medium to high (T6/T651 temper comparable to some 5xxx structural alloys)

- Corrosion resistance: Very good in marine and industrial atmospheres

- Weldability: Good, with acceptable strength loss in the heat‑affected zone

- Machinability: Good in T6/T651; suitable for precision machined parts

- Weight savings: ~1/3 the density of steel, enabling lightweight structures

- Form availability: Round, square, and flat bars in a wide range of diameters/thicknesses

2. Typical Chemical Composition of 6082 Alloy

Values are nominal ranges; exact composition may vary slightly by standard (EN, ISO, ASTM, GB) and supplier.

| Element | Symbol | Typical Content (wt%) |

|---|---|---|

| Aluminum | Al | Balance |

| Magnesium | Mg | 0.60 – 1.20 |

| Silicon | Si | 0.70 – 1.30 |

| Manganese | Mn | 0.40 – 1.00 |

| Iron | Fe | ≤ 0.50 |

| Chromium | Cr | ≤ 0.25 |

| Zinc | Zn | ≤ 0.20 |

| Titanium | Ti | ≤ 0.10 |

| Copper | Cu | ≤ 0.10 |

| Others (each) | — | ≤ 0.05 |

| Others (total) | — | ≤ 0.15 |

Design note:

- Mg + Si form Mg₂Si strengthening precipitates during heat treatment, giving 6082 its structural strength.

- Mn refines grain structure, improves toughness, and enhances resistance to impact and stress corrosion.

3. Mechanical Properties (Typical Values)

Typical mechanical properties for 6082 marine aluminum bar in common tempers:

| Property | Unit | 6082‑T6 / T651 | 6082‑T5 / T52 | 6082‑O (annealed) |

|---|---|---|---|---|

| Tensile Strength (Rm) | MPa | 295 – 340 | 250 – 290 | 125 – 170 |

| 0.2% Proof Strength (Rp0.2) | MPa | 240 – 280 | 200 – 240 | 55 – 80 |

| Elongation (A50) | % | 8 – 12 | 10 – 14 | 16 – 22 |

| Brinell Hardness (HBW) | — | 85 – 100 | 75 – 90 | 35 – 45 |

| Modulus of Elasticity | GPa | ~70 | ~70 | ~70 |

| Shear Strength (typical) | MPa | 190 – 210 | 170 – 190 | 80 – 100 |

| Fatigue Strength (rotating, ~5×10⁸ cycles) | MPa | ~95 – 110 | ~85 – 100 | — |

Values are indicative; refer to specific material test certificates for design‑critical calculations.

4. Physical and Corrosion Performance

4.1 Physical Properties

| Property | Unit | Typical Value |

|---|---|---|

| Density | g/cm³ | 2.70 |

| Melting Range | °C | 555 – 650 |

| Thermal Conductivity | W/m·K | 160 – 180 |

| Electrical Conductivity | % IACS | 30 – 40 |

| Coefficient of Thermal Expansion (20–100 °C) | µm/m·K | 23 – 24 |

| Specific Heat | J/kg·K | ~900 |

4.2 Corrosion Behavior in Marine Environments

- General corrosion: Very good resistance in seawater and salt‑laden atmospheres when properly designed and drained.

- Pitting corrosion: Low tendency, improved by correct alloying and surface finishing (anodizing or marine‑grade coatings).

- Stress corrosion cracking: Better performance than high‑strength 2xxx and 7xxx alloys, especially beneficial for welded and restrained structures.

- Galvanic corrosion: Must be managed when connected to copper alloys, carbon steel, or stainless steel in seawater; proper isolation and sacrificial anodes are recommended.

5. Technical Specifications for Marine Bars

Typical supply ranges and tolerances (values may vary by mill and standard such as EN 755, ASTM B221, or equivalent):

5.1 Dimensional Range

| Parameter | Typical Range |

|---|---|

| Round bar diameter | 8 – 400 mm |

| Square / rectangular bar side | 10 – 300 mm |

| Length | 3 – 6 m standard; custom lengths on request |

| Length tolerance | ±3 – 5 mm (depending on length and spec) |

5.2 Dimensional Tolerances (Indicative)

| Diameter / Side (mm) | Typical Dimensional Tolerance |

|---|---|

| ≤ 30 | ±0.15 – 0.25 mm |

| 30 – 80 | ±0.25 – 0.50 mm |

| 80 – 150 | ±0.50 – 1.00 mm |

| > 150 | Per agreement / mill standard |

5.3 Standard Tempers for Marine Use

| Temper | Description | Marine Relevance |

|---|---|---|

| O | Fully annealed, lowest strength, max formability | Bending, flanging, deep forming prior to re‑heat‑treat |

| T5 | Cooled from extrusion and artificially aged | Structural sections where moderate strength is adequate |

| T6 | Solution heat treated and artificially aged | High‑strength marine components and machined parts |

| T651 | T6 + stress‑relieved by stretching | Precision machining; reduced distortion after machining |

| T52 | Stress‑relieved by stretching from T5 | Better dimensional stability than T5 |

6. Processing Performance

6.1 Machinability

- 6082‑T6/T651 offers good chip formation, stable cutting forces, and suitable surface finish for:

- Shafts, hubs, couplings

- Winch and hoist components

- Precision brackets and mounting plates

Machining considerations:

| Parameter | Recommendation (typical) |

|---|---|

| Cutting speed (carbide tools) | 200 – 500 m/min |

| Feed rate | Medium; optimize to avoid built‑up edge |

| Coolant | Water‑soluble cutting fluids recommended |

| Tooling | Sharp carbide tools with positive rake angles |

6.2 Weldability

6082 is readily welded by MIG and TIG methods.

| Aspect | Comment |

|---|---|

| Weldability | Good; widely used in welded marine structures |

| Common filler wires | 5356, 5183, 5556 (for marine) |

| Heat‑affected zone (HAZ) | Local strength reduction vs. parent T6/T651 material |

| Post‑weld treatment | If feasible, artificial aging or overdesign in HAZ region |

For critical structures such as hull girders or crane booms, design should account for reduced yield strength in the HAZ (often similar to a T4‑like condition).

6.3 Forming and Bending

- Cold bending is possible, particularly in O or T4 temper.

- T6/T651 can be bent with larger radii; risk of cracking increases with tight radii and low temperatures.

- Pre‑heating to ~100–150 °C can improve formability for demanding bends.

7. Main Marine and Offshore Applications

6082 marine aluminum bars are used where structural integrity, corrosion resistance, and weight savings are critical.

7.1 Shipbuilding and Workboats

| Component Type | Typical Use Cases |

|---|---|

| Structural members | Frames, girders, stiffeners, deck beams |

| Deck equipment | Bollards, fairleads, chocks, cleats, pad‑eyes |

| Mechanical parts | Shafts (non‑critical), pulleys, guide rollers |

| Superstructure details | Handrails, ladders, platforms, brackets |

Benefit: Reduces vessel weight, increasing payload capacity and fuel efficiency while maintaining mechanical strength.

7.2 Offshore Platforms and Marine Infrastructure

| Area | Application Examples |

|---|---|

| Offshore platforms | Walkways, access platforms, support brackets, guards |

| Port and harbor equipment | Fender backing plates, gangway structures, mooring systems |

| Offshore wind | Nacelle access structures, platforms, ladder systems |

| Floating structures | Floating pontoons, ramps, and connection hardware |

Benefit: Long service life in harsh saltwater exposure with minimal maintenance compared to carbon steel.

7.3 Marine Handling & Deck Machinery

- Winch frames and drums (non‑wear surfaces)

- Lifting beams and spreader bars

- Davit arms, crane booms (light/medium duty)

- Guide rails, bearing housings, and brackets

Benefit: Strong yet lightweight equipment, reduced inertial loads, easier manual handling, and lower power consumption for driven systems.

7.4 Special Marine & Industrial Uses

- Heat‑dissipating bars and manifolds where corrosion resistance is needed

- Structural rails and frames in desalination plants

- Corrosion‑resistant supports in chemical and fertilizer terminals

- Structural parts in high‑speed patrol boats, passenger ferries, and crew transfer vessels

8. Advantages of 6082 Marine Aluminum Bars in Design

8.1 Weight Reduction and Efficiency

- Density of ~2.70 g/cm³ vs. ~7.85 g/cm³ for steel.

- Allows larger structures to stay within weight limits and reduces draft and fuel consumption.

8.2 Balanced Strength and Ductility

- Provides a robust compromise between:

- Strength levels adequate for most marine structural uses

- Sufficient ductility for forming, bending, and absorbing impact loads.

8.3 Lifecycle Cost Savings

- Reduced maintenance due to inherent corrosion resistance.

- Lower painting/coating frequency vs. carbon steels.

- Good recyclability with retained material properties, supporting sustainable design.

8.4 Design Flexibility

- Available in multiple bar geometries and tempers.

- Suitable for:

- Machined precision parts

- Welded, bolted, and hybrid structures

- Integration with extrusions, plates, and forgings in the same alloy family

9. Selection and Design Guidelines

When specifying 6082 marine aluminum bar, consider:

| Design Factor | Guideline |

|---|---|

| Environment | For continuous seawater immersion, use proper isolation between dissimilar metals and consider protective coatings. |

| Strength level | Choose T6/T651 for maximum strength; consider T52/T5 where forming or stress relief is needed. |

| Welding extent | For heavily welded structures, design around reduced HAZ strength or use thicker sections locally. |

| Certification | For classed vessels, ensure material complies with relevant standards (e.g., DNV, ABS, LR) and marine aluminum specifications. |

| Surface finish | Consider anodizing or marine‑grade coatings for aesthetics, extra pitting resistance, and easy cleaning. |

6082 marine aluminum bar is a versatile, robust material for industrial marine design and construction. Its combination of:

- Good marine corrosion resistance

- Medium‑high structural strength

- Reliable weldability and machinability

- Significant weight savings versus steel

makes it a preferred choice for shipyards, offshore fabricators, marine equipment manufacturers, and port infrastructure projects.

By carefully selecting temper, dimensions, and protection systems, designers can achieve long‑lasting, lightweight, and cost‑effective marine structures with 6082 aluminum bars at the core of their solutions.

Related Products

Marine grade aluminum solid bar

Marine Grade Aluminum Solid Bars are produced from premium aluminum alloys optimized for saltwater exposure, such as 5083, 5052, 6061, and 6082. These alloys offer unparalleled resistance to corrosion caused by seawater, salt spray, and marine atmospheres, while maintaining excellent mechanical strength and toughness.

View Details6082 marine aluminum rod & bar

6082 Aluminum Rods & Bars are extruded or rolled products manufactured from 6082 aluminum alloy — a thermally treated (typically T6 temper) aluminum-magnesium-silicon alloy that balances high tensile strength, good weldability, and excellent corrosion resistance.

View DetailsMarine aluminum hexagonal bars

Marine Grade Aluminum Hexagonal Bars are produced from premium corrosion-resistant aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsMarine aluminum hollow bars

Marine Grade Aluminum Hollow Bars are fabricated from high-quality alloys such as 5083, 5052, 6061, and 6082, all known for their exceptional resistance to seawater corrosion, salt spray, and marine atmospheres.

View DetailsRelated Blog

6082 Marine Aluminum Hexagonal Bars for Offshore Marine Construction Parts

6082 Marine Aluminum Hexagonal Bars for Offshore Marine Construction Parts: Unveiling Their Functional Excellence and Unique ApplicationsWhen it comes to the demanding realm of offshore marine construction, material selection is to ensuring longevity, saf

View Details6082 Marine Aluminum Hollow Bars for Custom Boat Frame Solutions

6082 Marine Aluminum Hollow Bars for Custom Boat Frame Solutions In modern boatbuilding, frame design has evolved from heavy, overbuilt structures to lightweight, precision-engineered systems.

View Details6082 Marine Grade Aluminum Solid Bar for Saltwater Resistant Marine Parts

The 6082 marine grade aluminum solid bar is a high‑strength, corrosion‑resistant alloy widely used for structural components in harsh marine environments. It offers an excellent balance of strength, workability, and long‑term durability, maki.

View Details6082 Marine Grade Aluminum Solid Bar for Boat Deck Reinforcements

When it comes to marine vessel construction and refurbishment, selecting the right materials is vital for ensuring durability, performance, and safety. Among various options.

View Details6082 Marine Aluminum Bar for Custom Boat Fabrication and Reinforcement

When it comes to custom boat fabrication and structural reinforcement in marine environments, material choice is paramount. The 6082 Marine Aluminum Bar stands out as a superior solution that combines strength, corrosion resistance.

View Details6082 Marine Aluminum Bar for High Strength Marine Components

In the demanding world of marine engineering, the choice of materials defines not only the longevity but also the safety and performance of vessels. Among the plethora of metal options.

View Details

Leave a Message