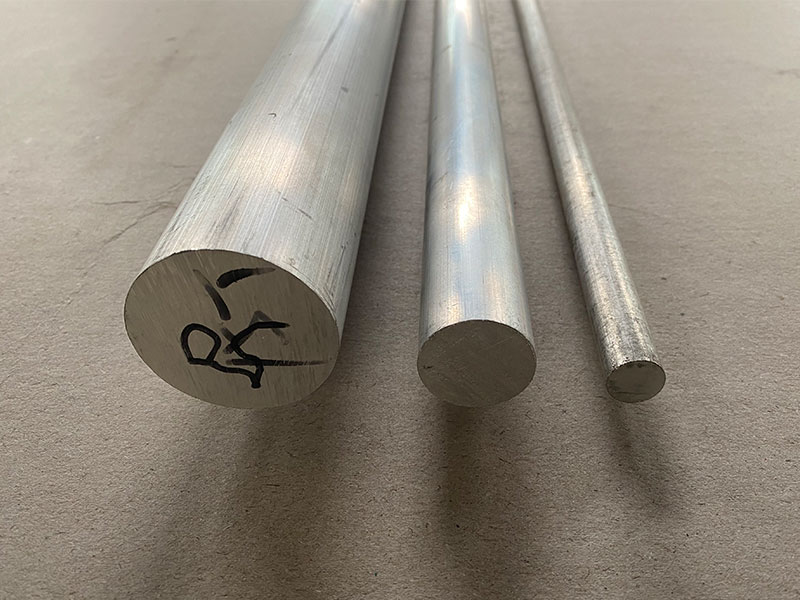

6082 Marine Grade Aluminum Solid Bar for Saltwater Resistant Marine Parts

The 6082 Marine grade aluminum solid bar is a high‑strength, corrosion‑resistant alloy widely used for structural components in harsh marine environments. It offers an excellent balance of strength, workability, and long‑term durability, making it a reliable choice for boat builders, offshore equipment manufacturers, and precision marine fabricators.

6082 is a medium‑strength aluminum–magnesium–silicon alloy in the 6xxx series. It is often considered a “structural” alloy and is one of the strongest commercially available 6xxx alloys, with good weldability and excellent resistance to seawater corrosion.

characteristics at a glance:

|----------------------------------|-------------------------------------------------------------------------------------|| Alloy designation | 6082 (Al-Mg-Si) || Product form | Solid round / square / rectangular bar || Temper options | T6, T651, T5 (others on request) || Primary strength | High (220–310 MPa yield, depending on temper and size) || Corrosion resistance | Excellent in saltwater and marine atmospheres || Weldability | Good, suitable for common marine fabrication methods || Machinability | Medium–good, improved in T6/T651 tempers || Weight | ~1/3 the density of steel, ideal for weight‑critical marine structures |

2. Chemical Composition

6082 is an Al–Mg–Si alloy, with controlled additions of manganese and other elements to optimize strength and corrosion performance.

Typical chemical composition of 6082 aluminum alloy (wt%):

| Element | Typical Range (%) | Function in Alloy |

|---|---|---|

| Si | 0.70 – 1.30 | Forms Mg₂Si for precipitation hardening; strength |

| Fe | ≤ 0.50 | Kept low to maintain toughness and corrosion resistance |

| Cu | ≤ 0.10 | Limited to protect corrosion resistance |

| Mn | 0.40 – 1.00 | Grain refinement, improves strength and toughness |

| Mg | 0.60 – 1.20 | strengthening element (Mg₂Si phase) |

| Cr | ≤ 0.25 | Stabilizes grain structure |

| Zn | ≤ 0.20 | Controlled to maintain corrosion resistance |

| Ti | ≤ 0.10 | Grain refiner, improves mechanical properties |

| Others (each) | ≤ 0.05 | Impurity control |

| Others (total) | ≤ 0.15 | Impurity control |

| Al | Balance | Matrix metal |

3. Mechanical Properties & Performance

Mechanical properties vary by temper and cross‑section. For marine structural use, T6 and T651 tempers are common, offering a good combination of strength and toughness.

Typical mechanical properties at room temperature (for reference only):

| Property | Unit | 6082-T6 / T651 (Bar) |

|---|---|---|

| Tensile Strength, Rm | MPa | 290 – 340 |

| 0.2% Proof Strength, Rp0.2 | MPa | 240 – 300 |

| Elongation (A50) | % | 8 – 14 |

| Brinell Hardness (HBW) | HB | 85 – 100 |

| Modulus of Elasticity | GPa | ~70 |

| Shear Strength (typical) | MPa | ~200 |

| Poisson’s Ratio | – | ~0.33 |

| Density | g/cm³ | ~2.70 |

performance notes:

- High specific strength: Delivers strong load‑bearing capacity at approximately one‑third the weight of steel, enabling lighter hulls and frames.

- Good fatigue resistance: Well‑suited to dynamic marine loads such as wave impact, vibration, and cyclic bending.

- Stable properties in marine climates: Maintains strength and stiffness across typical marine operating temperatures.

4. Corrosion Resistance in Saltwater Environments

6082 is designed to resist chloride‑rich environments, including seawater and marine atmospheres.

Corrosion Behavior

| Property / Behavior | Performance in Marine Use |

|---|---|

| General corrosion in seawater | Very good; low uniform corrosion rates |

| Pitting resistance | Good when proper design and surface protection are used |

| Stress‑corrosion cracking | Good resistance compared to higher‑strength 2xxx/7xxx |

| Galvanic corrosion (mixed metals) | Requires isolation from more noble metals (e.g., stainless) |

| Protective coatings | Compatible with anodizing, marine paints, and sealants |

For long‑term marine exposure:

- Use insulating washers, bushings, or sealants between 6082 and stainless or copper alloys to minimize galvanic couples.

- Consider anodizing or marine‑grade coatings for enhanced cosmetic and pitting protection, especially in splash zones and crevice areas.

5. Technical Specifications of 6082 Solid Bar

Solid bars are supplied in a wide range of diameters and tempers to match different marine applications.

Typical dimensional and technical specifications:

| Parameter | Typical Range / Options |

|---|---|

| Diameter (round bar) | 6 mm – 300+ mm |

| Square / flat bar sizes | On request, typically 10×10 mm up to 200×50 mm |

| Lengths | 3 m, 6 m standard; custom cut lengths available |

| Tempers | T6, T651 (stress‑relieved), T5, O (on request) |

| Straightness tolerance | As per EN 755 / ASTM B221 (or equivalent) |

| Dimensional tolerance | h11 / h12 or as specified by customer |

| Surface condition | Mill finish, brushed, or pre‑anodized (optional) |

| Standards | EN AW‑6082, ASTM B221, ISO / GB equivalents |

T6 vs. T651 for marine bars:

| Temper | Main Treatment | Typical Use in Marine Projects |

|---|---|---|

| T6 | Solution heat treated and artificially aged | General structural members, where minimal machining needed |

| T651 | T6 + stress‑relief stretching | Precision machined parts requiring high dimensional stability |

6. Workability: Welding, Machining, and Forming

6.1 Welding

6082 is well‑suited to common aluminum welding processes:

| Aspect | Performance / Recommendation |

|---|---|

| Weldability | Good |

| Recommended process | TIG (GTAW), MIG (GMAW) |

| Typical filler wire | 5356 or 4043, depending on design and corrosion priorities |

| Post‑weld strength | Reduced in HAZ vs. base T6/T651 material |

For critical structures, designs should account for reduced strength in the heat‑affected zone (HAZ), or the weld area can be re‑qualified by testing.

6.2 Machining

- Medium‑good machinability, especially in T6/T651.

- Produces clean chips with proper tooling and coolant.

- Suitable for threading, boring, slotting, and precision milling.

6.3 Forming and Bending

- Cold forming is possible but more limited in higher tempers (T6/T651).

- For tight radii, temper O or T4 is preferred before forming, followed by appropriate heat treatment if required.

7. Typical Marine Applications

6082 marine grade solid bars are widely used in both coastal and offshore projects where structural integrity and corrosion resistance are critical.

Common marine use cases:

| Application Area | Example Parts & Components |

|---|---|

| Boat & shipbuilding | Keel and deck fittings, cleats, bollards, handrails, supports |

| Offshore platforms | Brackets, walk‑way supports, guardrails, ladder rungs |

| Underwater / sub‑sea hardware | Light load‑bearing pins, spacers, structural rods (with coatings) |

| Marina & port infrastructure | Fender brackets, mooring accessories, gangway supports |

| Marine equipment & machinery | Winch components, sheaves, housings, instrument frames |

| Recreational marine products | Masts for small craft, frame bars, trolling hardware, racks |

In many of these roles, 6082 replaces steel to reduce weight, cut maintenance costs, and improve corrosion performance.

8. Benefits for Marine Designers and Fabricators

8.1 Weight Reduction

- Density ~2.70 g/cm³ vs. ~7.85 g/cm³ for carbon steel.

- Enables lighter hulls, superstructures, and decks, which:

- Improve fuel efficiency.

- Increase payload capacity.

- Enhance handling and speed for small vessels.

8.2 Long‑Term Durability

- High resistance to saltwater corrosion and marine atmospheres.

- Reduced risk of rust, scaling, and material loss.

- Lower maintenance frequency and longer service intervals.

8.3 Fabrication Efficiency

- Easy to cut, weld, machine, and drill with standard aluminum equipment.

- Available in a wide range of diameters and lengths.

- Good dimensional stability in T651 temper reduces distortion in machined parts.

8.4 Design Flexibility

- Suitable for both primary structures (frames, supports) and secondary hardware (fittings, brackets).

- Compatible with standard joining methods:

- Welding

- Mechanical fastening (bolts, rivets)

- Adhesive bonding (with surface preparation)

9. Comparison with Other Marine Aluminum Alloys

Choosing the right alloy is critical. 6082 sits between the easily formed 5xxx series and the very high‑strength 7xxx series.

| Alloy | Features | Marine Use Notes |

|---|---|---|

| 5052 | Good corrosion, very good formability | Thin plate, tanks, non‑structural components |

| 5083 | Very high corrosion, high strength | Hulls, ship structures, especially in welded form |

| 6082 | High strength, good corrosion, machinable | Structural bars, machined marine fittings, supports |

| 6061 | General‑purpose, moderate strength | Light structures; 6082 often preferred for strength |

| 7075 | Very high strength, poorer corrosion | Limited marine use, requires strict protection |

6082 is an excellent choice when you need:

- Better machinability and bar availability than 5xxx plate alloys.

- Higher strength than 6061 in bar form.

- Reliable corrosion resistance without the complexity of 7xxx protection systems.

6082 Marine grade aluminum solid bar combines:

- High specific strength for load‑bearing marine structures.

- Excellent resistance to saltwater corrosion.

- Good weldability and machinability for efficient fabrication.

- Wide dimensional range to support anything from small fittings to large frames.

For designers and builders of boats, offshore structures, marinas, and marine equipment, 6082 solid bar provides a robust, long‑life solution that reduces weight and maintenance while maintaining safety and performance in demanding saltwater environments.

Related Products

Marine aluminum hollow bars

Marine Grade Aluminum Hollow Bars are fabricated from high-quality alloys such as 5083, 5052, 6061, and 6082, all known for their exceptional resistance to seawater corrosion, salt spray, and marine atmospheres.

View DetailsMarine aluminum hexagonal bars

Marine Grade Aluminum Hexagonal Bars are produced from premium corrosion-resistant aluminum alloys such as 5083, 5052, 6061, and 6082.

View Details6082 marine aluminum rod & bar

6082 Aluminum Rods & Bars are extruded or rolled products manufactured from 6082 aluminum alloy — a thermally treated (typically T6 temper) aluminum-magnesium-silicon alloy that balances high tensile strength, good weldability, and excellent corrosion resistance.

View DetailsMarine grade aluminum solid bar

Marine Grade Aluminum Solid Bars are produced from premium aluminum alloys optimized for saltwater exposure, such as 5083, 5052, 6061, and 6082. These alloys offer unparalleled resistance to corrosion caused by seawater, salt spray, and marine atmospheres, while maintaining excellent mechanical strength and toughness.

View DetailsRelated Blog

6082 Marine Grade Aluminum Solid Bar for Boat Deck Reinforcements

When it comes to marine vessel construction and refurbishment, selecting the right materials is vital for ensuring durability, performance, and safety. Among various options.

View Details6082 Marine Aluminum Bar for Custom Boat Fabrication and Reinforcement

When it comes to custom boat fabrication and structural reinforcement in marine environments, material choice is paramount. The 6082 Marine Aluminum Bar stands out as a superior solution that combines strength, corrosion resistance.

View Details6082 Marine Grade Aluminum Solid Bar for Marine Hull Strengthening

The 6082 marine grade aluminum solid bar is widely used for reinforcing hull structures, decks, and load‑bearing components in ships and offshore vessels. It combines high strength, excellent corrosion resistance, and good weldability, .

View Details6082 Marine Aluminum Hollow Bars for Custom Boat Frame Solutions

6082 Marine Aluminum Hollow Bars for Custom Boat Frame Solutions In modern boatbuilding, frame design has evolved from heavy, overbuilt structures to lightweight, precision-engineered systems.

View Details6082 Marine Aluminum Bar for Industrial Marine Design and Construction

The 6082 marine aluminum bar is a medium‑strength, heat‑treatable wrought alloy designed for demanding marine and offshore environments. Combining good corrosion resistance, excellent machining performance, and reliable weldability, it.

View Details6082 Marine Grade Aluminum Solid Bar for Saltwater Resistant Marine Parts

The 6082 marine grade aluminum solid bar is a high‑strength, corrosion‑resistant alloy widely used for structural components in harsh marine environments. It offers an excellent balance of strength, workability, and long‑term durability, maki.

View Details

Leave a Message