6082 Marine Aluminum Hollow Bars for Custom Boat Frame Solutions

6082 Marine aluminum hollow bars for Custom Boat Frame Solutions

In modern boatbuilding, frame design has evolved from heavy, overbuilt structures to lightweight, precision-engineered systems. At the center of this shift are 6082 Marine aluminum hollow bars—an alloy and form factor that give naval architects and builders a new level of freedom for custom frames, towers, rails, and support structures.

Instead of looking at 6082 hollow bars as just another metal stock, it helps to see them as a structural “language” for boat frames: a way to transmit forces cleanly, reduce weight intelligently, and integrate equipment without compromising safety or durability.

Below is a practical and technical overview of 6082 Marine aluminum hollow bars, with a focus on what matters most when you are designing or specifying custom frame solutions.

Why 6082 for Marine Frames?

6082 is a medium-strength aluminum–magnesium–silicon alloy in the 6xxx series. In many marine framing applications, it is considered a strong alternative to 6061, especially where higher strength and better resistance to fatigue are desired.

For boat frames, towers, and superstructures, hollow bars in 6082 deliver a few critical advantages:

- High strength-to-weight ratio for deck structures, T-tops, radar arches, and rail systems

- Excellent corrosion resistance in marine atmospheres, especially when properly coated or anodized

- Good weldability and machinability, allowing precise custom designs and clean joints

- Dimensional stability for long sections and complex welded frames

The hollow bar form is particularly important. You get stiffness and bending resistance with a fraction of the weight of solid bars, which is ideal for overhead structures or extensive tubular framing where every kilogram counts.

Functional Role of Hollow Bars in Boat Frames

A 6082 marine aluminum hollow bar is not just a tube. In a well-thought-out frame design, it serves multiple structural and functional roles simultaneously.

Typical functions include:

- Main frame members for T-tops, hardtops, radar masts, and flybridge supports

- Perimeter rails and safety barriers with controlled flexibility and impact resistance

- Ladder and grab rail systems with consistent grip diameter and smooth transitions

- Mounting backbones for antennas, navigation lights, solar panels, and instruments

- Integration channels for concealed wiring or hoses inside the hollow section

By routing loads through hollow profiles—compression, tension, bending, and torsion—designers can tune the geometry to match real-world wave, wind, and vibration forces. The result is a frame that feels rigid where it should, but has enough controlled flexibility to avoid fatigue cracking.

Typical Applications in Custom Boat Solutions

6082 Marine aluminum hollow bars are widely used across:

- Offshore fishing boats for T-top structures, rocket launchers, and leaning posts

- RIBs and patrol craft for lightweight, rugged guard rails and equipment frames

- Sailing yachts for biminis, sprayhood frames, pushpits, pulpits, and arch structures

- Commercial workboats for crane support frames, davits, and protective cages

- Passenger and sightseeing vessels for canopy frames, stair rails, and safety systems

Their machinability allows boatbuilders to cut custom joints, tapered ends, and precise connection points for fittings. Complex assemblies—such as folding towers or height-adjustable frames—are much easier to realize using consistent, weldable hollow bar stock.

Alloy Tempers: Matching Strength to Application

6082 is available in several tempers, each representing a different combination of mechanical properties and formability. In marine frame applications, the most common tempers are:

- T6: Solution heat-treated and artificially aged. High strength, ideal for highly loaded structural members such as mast supports, large arches, and support columns.

- T5: Cooled from an elevated-temperature shaping process and then artificially aged. Moderate to high strength with good dimensional stability, suitable for standard frame bars and railings.

- T4 or O: For more complex bending or forming operations before final heat treatment; less common in finished marine frames but useful where tight radii or intricate curves are needed.

Choosing the temper is a balancing act between strength, weldability, and formability. For welded marine structures, designers often prefer 6082-T6 for its strength, but you must account for the softening in the heat-affected zone around welds. Correct weld design, gusseting, and load path planning are essential.

Mechanical and Dimensional Parameters

parameters when specifying 6082 Marine aluminum hollow bars include:

- Outside diameter (OD): Typically from about 10 mm to over 200 mm, depending on vessel size and application

- Wall thickness: Thin walls for light railings, thicker walls for high-load bearing frames; common ranges from 1.5 mm to 12 mm or more

- Length: Stock bars often come in 6 m or custom-cut lengths to minimize waste and joints

- Tolerances: Controlled OD, wall thickness, and straightness are crucial for clean alignment and accurate fitting of connectors and accessories

Typical mechanical properties for 6082-T6 (indicative values, actual may vary by standard and producer):

- Tensile strength: roughly 290–340 MPa

- Yield strength (0.2% proof): roughly 240–300 MPa

- Elongation at break: about 8–12% depending on size and standard

- Modulus of elasticity: approx. 70 GPa

These values give hollow bars enough stiffness for long spans while still maintaining some ductility to absorb impact and vibration.

Implementation Standards and Marine Compliance

For marine use, 6082 hollow bars are generally produced and certified against recognized international standards. Common references include:

- EN 755 series for extruded aluminum bars, tubes, and profiles

- EN 573 series for chemical composition

- ASTM B241 / B429 for seamless and structural aluminum pipe and tube (where applicable)

- ISO and EN standards relating to mechanical properties and dimensional tolerances

For vessels falling under classification societies or flag regulations (such as DNV, ABS, LR, or Bureau Veritas), frame materials and weld procedures may need to meet specific marine rules. That can include traceable mill certificates, mechanical test reports, and approved welding procedures for 6xxx-series aluminum.

Corrosion Resistance and Surface Protection

6082 already offers good resistance to atmospheric and marine environments thanks to its magnesium and silicon content. For boat frames, hollow bars are often further protected through:

- Marine-grade anodizing for improved surface hardness and corrosion resistance

- Powder coating for aesthetic finishes and extra environmental protection

- Carefully selected sealants and isolators when connecting to stainless steel or other metals, to minimize galvanic corrosion

The hollow geometry also makes internal corrosion control important. For high-end installations, drain holes or venting may be incorporated so that moisture does not become trapped inside closed sections.

Chemical Composition of 6082 Alloy

Typical chemical composition (mass percent) for 6082 aluminum alloy is:

| Element | Typical Range (%) |

|---|---|

| Silicon (Si) | 0.70 – 1.30 |

| Magnesium (Mg) | 0.60 – 1.20 |

| Manganese (Mn) | 0.40 – 1.00 |

| Iron (Fe) | ≤ 0.50 |

| Copper (Cu) | ≤ 0.10 |

| Chromium (Cr) | ≤ 0.25 |

| Zinc (Zn) | ≤ 0.20 |

| Titanium (Ti) | ≤ 0.10 |

| Others (each) | ≤ 0.05 |

| Others (total) | ≤ 0.15 |

| Aluminum (Al) | Balance |

The combined Mg and Si content forms magnesium silicide (Mg2Si), which is the basis for the heat-treatable strengthening in 6xxx-series alloys. Manganese enhances toughness and resistance to fatigue—valuable properties for frame members continuously stressed by wave motion.

When you view 6082 Marine aluminum hollow bars not as separate parts but as a connected system, a more efficient boat frame becomes possible. Consistent alloy, temper, and cross-section:

- Simplify welding and joining procedures

- Reduce inventory complexity for repairs and retrofits

- Allow modular upgrades such as new tops, additional rails, or integrated solar frames

Cable routing, lighting integration, instrument mounting, and passenger safety can all share the same structural “spine.” That is where the real value of 6082 hollow bars lies: they let you build strong, light, and versatile structures that are easy to customize and maintain over the life of the vessel.

For boatbuilders, refit yards, and designers seeking balance between strength, weight, and long-term durability, 6082 Marine aluminum hollow bars provide a reliable and highly adaptable foundation for custom frame solutions—from sleek yacht arches to rugged workboat superstructures.

Related Products

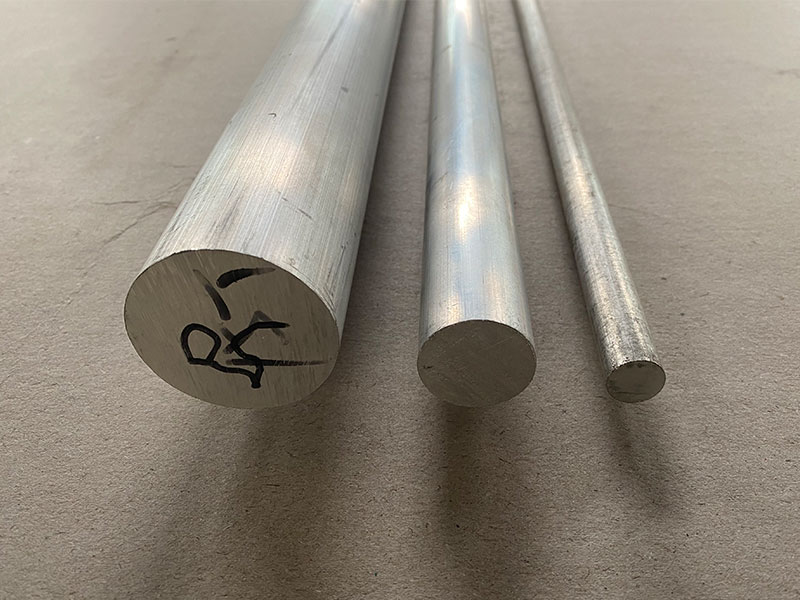

6082 marine aluminum rod & bar

6082 Aluminum Rods & Bars are extruded or rolled products manufactured from 6082 aluminum alloy — a thermally treated (typically T6 temper) aluminum-magnesium-silicon alloy that balances high tensile strength, good weldability, and excellent corrosion resistance.

View DetailsMarine grade aluminum solid bar

Marine Grade Aluminum Solid Bars are produced from premium aluminum alloys optimized for saltwater exposure, such as 5083, 5052, 6061, and 6082. These alloys offer unparalleled resistance to corrosion caused by seawater, salt spray, and marine atmospheres, while maintaining excellent mechanical strength and toughness.

View DetailsMarine aluminum hexagonal bars

Marine Grade Aluminum Hexagonal Bars are produced from premium corrosion-resistant aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsMarine aluminum hollow bars

Marine Grade Aluminum Hollow Bars are fabricated from high-quality alloys such as 5083, 5052, 6061, and 6082, all known for their exceptional resistance to seawater corrosion, salt spray, and marine atmospheres.

View DetailsRelated Blog

6082 Marine Grade Aluminum Solid Bar for Boat Deck Reinforcements

When it comes to marine vessel construction and refurbishment, selecting the right materials is vital for ensuring durability, performance, and safety. Among various options.

View Details6082 Marine Grade Aluminum Solid Bar for Saltwater Resistant Marine Parts

The 6082 marine grade aluminum solid bar is a high‑strength, corrosion‑resistant alloy widely used for structural components in harsh marine environments. It offers an excellent balance of strength, workability, and long‑term durability, maki.

View Details6082 Marine Aluminum Bar for Industrial Marine Design and Construction

The 6082 marine aluminum bar is a medium‑strength, heat‑treatable wrought alloy designed for demanding marine and offshore environments. Combining good corrosion resistance, excellent machining performance, and reliable weldability, it.

View Details6082 Marine Aluminum Hexagonal Bars for Offshore Marine Construction Parts

6082 Marine Aluminum Hexagonal Bars for Offshore Marine Construction Parts: Unveiling Their Functional Excellence and Unique ApplicationsWhen it comes to the demanding realm of offshore marine construction, material selection is to ensuring longevity, saf

View Details6082 Marine Grade Aluminum Solid Bar for Marine Hull Strengthening

The 6082 marine grade aluminum solid bar is widely used for reinforcing hull structures, decks, and load‑bearing components in ships and offshore vessels. It combines high strength, excellent corrosion resistance, and good weldability, .

View Details6082 Marine Aluminum Hollow Bars for Custom Boat Frame Solutions

6082 Marine Aluminum Hollow Bars for Custom Boat Frame Solutions In modern boatbuilding, frame design has evolved from heavy, overbuilt structures to lightweight, precision-engineered systems.

View Details

Leave a Message