Aluminum Elbow for Ship Hot Water and Heating Systems

In marine applications, especially in shipboard hot water and heating systems, the reliability and efficiency of piping components are paramount. Aluminum elbows serve as crucial connectors to change the direction of piping flows, maintaining system integrity while enduring the rigors of marine environments. Our Aluminum Elbow for Ship Hot Water and Heating Systems is specially engineered utilizing marine aluminum alloys that meet stringent performance and corrosion resistance requirements, ensuring long service life and optimal operational reliability.

The aluminum elbow mechanical fitting is used predominantly to alter piping directions, typically at 45°, 90°, or custom angles for process versatility. Designed specifically for use within hot water circulation and central heating lines on ships, these elbows exhibit strong resistance to corrosion caused by seawater and marine atmospheric conditions, while also offering excellent thermal conductivity for effective heat transfer.

Benefits:

- Marine-grade corrosion resistance

- Lightweight compared to steel alternatives

- Excellent thermal conductivity

- Precise dimensional consistency for leak-free pipelining

- Compliance with marine industry standards

- Reduced maintenance for long-term use

Material and Alloy Composition

Our aluminum elbows are manufactured from high-purity marine aluminum alloys renowned for their strength-to-weight ratio, resistance to seawater corrosion, and weldability. The following alloy and temper capture the primary specifications incorporated into the elbow fittings:

Working with marine-grade aluminum, specifically in the context of elbows for shipboard hot water and heating systems, highlights the crucial interplay between material properties and demanding operational conditions. We're not just dealing with standard aluminum; the alloys we use here must resist seawater corrosion, withstand significant thermal cycling (think arctic to tropic deployments), and endure vibrations that would shake a lesser metal apart. The design of the elbow itself is critical; a poorly designed bend radius can introduce stress concentrations leading to premature failure, a costly and potentially dangerous outcome at sea. My experience shows that even minor variations in manufacturing processes, such as the heat treatment or welding techniques, can significantly impact the longevity and reliability of these components.

Beyond the technical specifications, I’ve seen firsthand the impact of a well-made elbow versus a poorly made one. A failed elbow on a long voyage, especially in harsh weather, is a serious problem – potentially leading to system failure, repair delays, and even crew discomfort. Therefore, quality control is paramount. We meticulously inspect every elbow for defects, testing for dimensional accuracy, metallurgical soundness, and corrosion resistance. It’s a point of pride for our team to know that our elbows are contributing to safe and efficient operation on ships across the globe, and that the reliability of our product directly translates to the comfort and safety of those working and travelling on board.

| Alloy | Temper | Primary Elements (wt%) | Typical Mechanical Properties | Standards Compliance |

|---|---|---|---|---|

| 5083 | H321 | Al Balance | Tensile strength: 290-350 MPa | ASTM B209, ISO 6361, and DNV GL Marine |

| Mg 4.0-4.9 | Yield strength: 125-300 MPa | ABS and Lloyd’s Register Marine Standards | ||

| Mn 0.4-1.0 | Elongation: minimum 12% | MIL-DTL-46027F | ||

| Cr 0.05-0.25 | Density: 2.66 g/cm³ |

Typical Corrosion Resistance: Excellent, suitable for direct seawater and hot water circulation.

Temper Conditions and Mechanical Characteristics

- Temper H321 signifies strain-hardened and stabilized condition, increasing dimensional stability under marine thermal cycles.

- Offers enhanced resistance to stress corrosion cracking — critical in hot water or mild steam environments.

- Aluminum elbows also resist scaling/internal buildup and provide freedom from degradation in temperatures range of 0–160°C (typical system operating limits).

Dimensional and Pressure Ratings

Sizes typically range from 1/2 inch to 8 inch nominal pipe size (NPS) to align with common ship piping diameters. Custom fabrication is available upon request.

| Nominal Size (NPS) | Radius (R) | Thickness (mm) | Pressure Clause |

|---|---|---|---|

| ½" to 2" | 1D (one diameter) | 3 - 5A (mild thinning) | Pressure up to 20 bar (standard seawater) |

| 2½" to 8" | 1.5D | 4 - 7 | Pressure up to 16 bar, depending on size |

Note: Pressure ratings depend on the full piping system design, aluminum grade and wall section used. The elbows comply with ASME B16.9 dimensional standard modified for aluminum fittings.

Implementation Standards and Certification

- ASTM B241/B241M - Standard Specification for Aluminum Alloy Seamless Pipe and Seamless Extruded Tube, used as the raw material form.

- DNV GL / ABS / Lloyd's Register certification for materials suitable in marine heating and water distribution systems.

- ISO 9001:2015 Quality Management Systems compliance for manufacturing processes.

- RoHS and REACH accredited for environmental safety considerations.

Applications

Primarily utilized in:

- Shipboard captive hot water systems

- Heating circulation loops (steam return elbows included with special internal coatings)

- Potable hot water feeding lines on ships and offshore platforms

- Hull insulation piping to prevent local condensation

- Industrial marine HVAC assemblies

Installation & Handling Guidelines

- Proper jointing preparation: Cleaning pipe ends and elbow interiors to ensure no soft contaminants or stains are buffered.

- Welding and joining: Maintain optimized vapor-tightolulu welding as per ABMA code; manual or orbital TIG welding preferred if seams exist.

- Thermal considerations: Account for tendon metals’ thermal expansion in steady pressurized hot systems—design axial allowance in piping runs.

- Testing protocols: Pressure and leak testing in situ post-installation to validate construction integrity.

Related Products

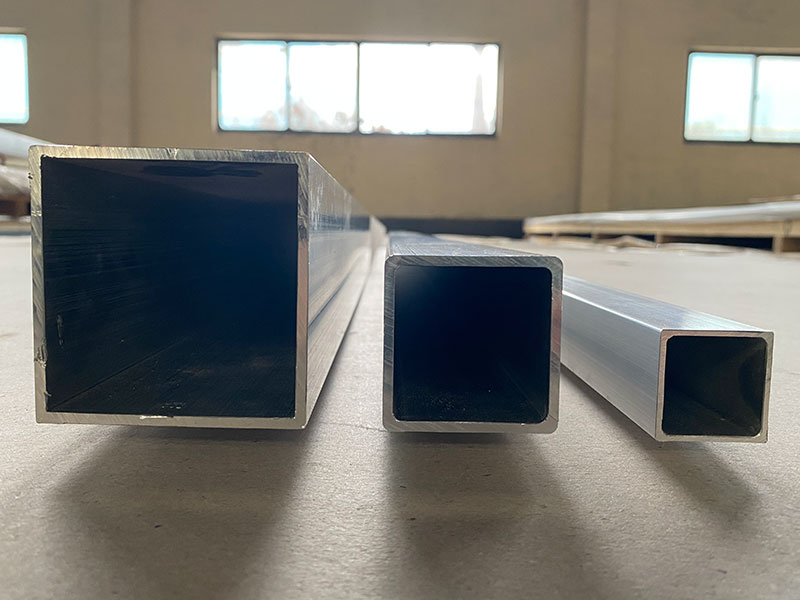

Marine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View DetailsMarine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View DetailsRelated Blog

5083 Marine Aluminum Tubes for Commercial Marine Parts

When it comes to commercial marine parts, durability, corrosion resistance, and strength are non-negotiable. Among various materials used in the marine industry, 5083 marine aluminum tubes is know as a premium choice.

View Details6082 Marine Aluminum Square Tubes for Corrosion Resistant Projects

When it comes to constructing structures that demand impeccable resistance to corrosion in harsh marine environments, 6082 marine aluminum square tubes is know as an industry favorite.

View DetailsAluminum Elbow for Saltwater Inlet and Outlet Systems

Aluminum elbows play a critical role in saltwater inlet and outlet systems used in marine, industrial, and desalination applications. Manufactured from high-quality aluminum alloys, these fittings are engineered to provide robust, corrosion-resistant.

View Details6061 Marine Aluminum Tubes for Marine Engineering Projects

Marine engineering demands materials that combine exceptional strength, corrosion resistance, and versatility for reliable performance in harsh seawater environments.

View DetailsMarine Aluminum Elbow for Seawater Drainage Systems

Our high-performance Marine Aluminum Elbow designed specifically for seawater drainage systems, offering exceptional corrosion resistance, superior strength, and compatibility with marine-grade piping systems. Learn about its alloy composition, tempering,

View Details5052 Marine Aluminum Tubes for Heavy Duty Marine Applications

When durability, corrosion resistance, and strength are paramount in marine environments, 5052 aluminum alloy tubes is know as the premium choice. Specifically engineered to meet the demanding specifications of heavy-duty marine applications.

View Details

Leave a Message