Marine Aluminum Pipe Elbow for High Flow Desalination Units

In the rapidly advancing realm of seawater desalination, marine aluminum pipe elbows play a pivotal role in ensuring the smooth and efficient operation of high flow desalination units. These specialized components, designed specifically for marine environments, address critical challenges such as corrosion resistance, fluid dynamics optimization, and structural integrity under demanding conditions.

Marine Aluminum Pipe Elbows

At its core, a pipe elbow is a fitting used to change the direction of fluid flow in piping systems. However, marine aluminum pipe elbows for desalination units are far from ordinary fittings. They are engineered from advanced marine-grade aluminum alloys, offering an excellent balance between strength, lightweight characteristics, and corrosion resistance—attributes essential for handling seawater's aggressive saline environment.

These elbows facilitate directional changes—typically 45°, 90°, and sometimes 180°—within piping infrastructure, allowing for optimized design of desalination units where space is a constraint and fluid pathway flexibility is needed.

Functional Significance in High Flow Desalination Units

- Enhanced Fluid Dynamics

Desalination systems, especially those using reverse osmosis or multi-stage flash (MSF) methods, demand precise fluid management to maximize throughput and minimize energy consumption. Marine aluminum elbows provide smooth flow transitions with minimal pressure drop. Their internal surface finish reduces turbulence and hydraulic losses, directly contributing to improved system efficiency.

- Corrosion and Wear Resistance

Seawater is a harsh medium, laden with salts and microorganisms that can expedite material degradation. The marine aluminum alloy’s natural anodic protection forms a protective oxide layer, coupled with specialized treatments to further enhance corrosion resistance. This prolongs service life and reduces downtime.

- Mechanical Strength under Variable Loads

Pipes in desalination units face fluctuating pressures and thermal stresses. The alloy tempering process—commonly T6 temper (solution heat-treated, quenched, and artificially aged)—imparts lasting mechanical strength and fatigue resistance while maintaining the material’s lightweight profile.

Technical Specifications and Parameters

Marine aluminum pipe elbows intended for desalination applications are manufactured according to stringent international standards, ensuring consistency and reliability:

- Material: Aluminium Alloy 6061-T6 or marine-grade 5083-H116

- Dimensions: Available in nominal pipe sizes ranging from 1 inch to 24 inches and beyond, with custom sizes for specialized units.

- Wall Thickness: PSG (Pipe Schedule Standard) or custom-thickness as required by operating pressure, typically Schedule 40 or heavier.

- Angle Variants: 45º, 90º (most common), 180º elbows.

- Surface Treatment: Anodization, fluoropolymer coating, or epoxy linings to enhance corrosion resistance and wear durability.

- Standards Compliance: ASTM B241 for seamless aluminum pipe extrusion, and ASME B16.9 for factory-made wrought steel butt-welded fittings adapted to aluminum.

Alloy Tempering and Chemical Composition

Heat treatment or tempering enhances the mechanical properties of aluminum alloys. For example, the commonly used 6061 aluminum alloy pipe elbows are typically supplied in the T6 temper condition:

| Alloy | Silicon (Si) % | Iron (Fe) % | Copper (Cu) % | Manganese (Mn) % | Magnesium (Mg) % | Chromium (Cr) % | Zinc (Zn) % | Titanium (Ti) % | Aluminum (Al) Balance |

|---|---|---|---|---|---|---|---|---|---|

| 6061 | 0.4 - 0.8 | 0.7 max | 0.15 - 0.4 | 0.15 max | 0.8 - 1.2 | 0.04 - 0.35 | 0.25 max | 0.15 max | Remainder |

Temper T6: Solution heat-treated at approximately 530°C (985°F), quenched rapidly, then artificially aged at 160-180°C. This produces superior tensile strength (~290 MPa yield) and appreciable hardness—a critical requirement to support the structural demands of complex desalination pipeline systems.

Some applications use marine aluminum alloy 5083-H116 known for exceptional corrosion resistance in seawater, dominated by magnesium (~4-4.9%) and minimal copper to limit susceptibility to intergranular attack.

Implementation Conditions

When integrating marine aluminum pipe elbows into high flow desalination units, several stages demand careful consideration:

- Fabrication: Welding follows precise procedures compatible with aluminum alloys to prevent defects, typically using TIG (Tungsten Inert Gas) welding. Weld zones undergo post-weld corrosion protection.

- Installation Environments: Optimized for both open seawater pumps intake systems and brine return pipelines, where elbows must preserve hydraulic efficiency under continuous operation.

- Maintenance: Installs are monitored for potential erosion from particulate matter; surface inspections aid early detection. Suitable protective coatings can be reapplied during periodic servicing cycles.

Related Products

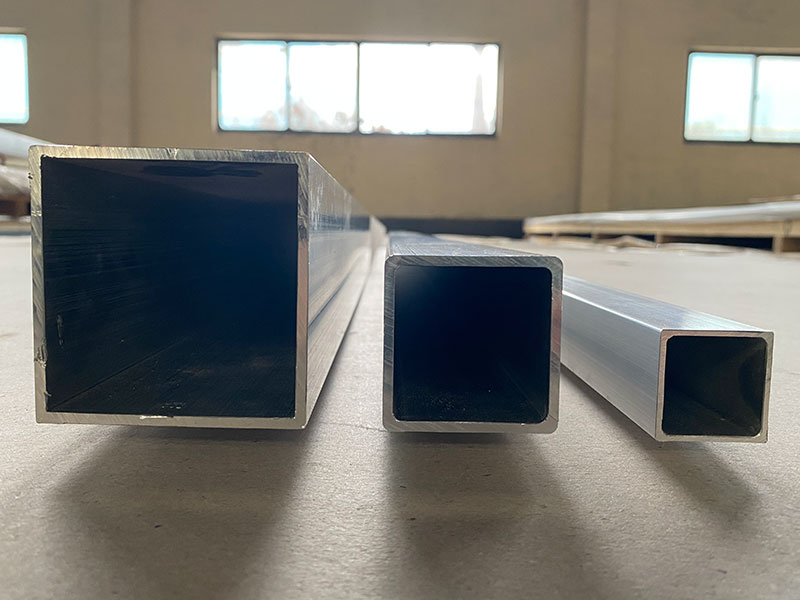

Custom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

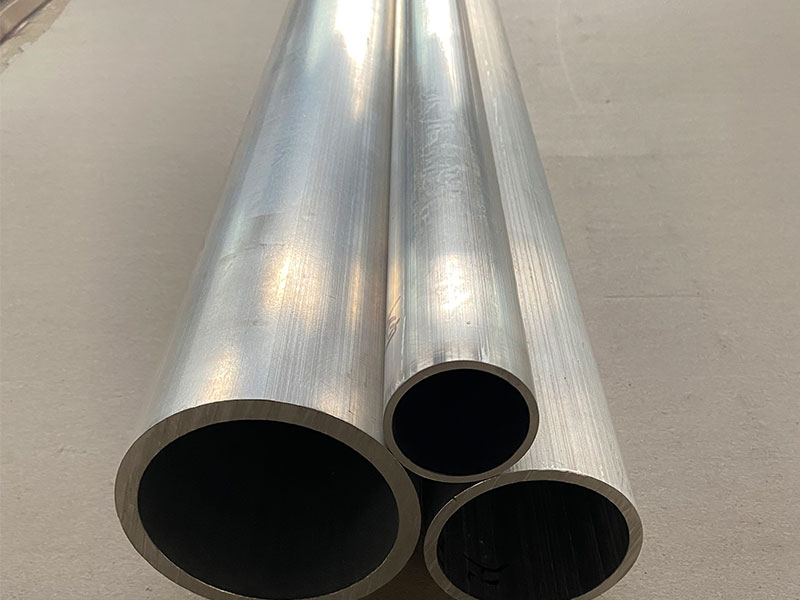

View DetailsMarine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View DetailsRelated Blog

5083 Marine Aluminum Tubes for Commercial Marine Parts

When it comes to commercial marine parts, durability, corrosion resistance, and strength are non-negotiable. Among various materials used in the marine industry, 5083 marine aluminum tubes is know as a premium choice.

View DetailsAluminum Pipe Elbow for Shipboard Refrigeration Lines

In the world of marine refrigeration systems, maintaining integrity, durability, and corrosion resistance is critical to ensure onboard equipment functions on long sea voyages.

View DetailsMarine Aluminum Elbow for Pressurized Water Systems on Ships

Explore our high-grade Marine Aluminum Elbow designed specifically for pressurized water systems onboard ships. Engineered for superior corrosion resistance, durability, and compliance with maritime standards, this product ensures reliable fluid dynamics

View Details5052 Marine Aluminum Tubes for Marine Vessel Hull Construction

When it comes to building resilient marine vessels, selecting the right materials is crucial. One outstanding option is 5052 Marine Aluminum, widely recognized for its excellent corrosion resistance and structural integrity.

View Details5083 Marine Aluminum Tubes for Coastal Boat Engineering Solutions

In coastal boat engineering, selecting materials that offer superior performance, durability, and resistance to harsh marine environments is critical. 5083 marine aluminum tubes present an exceptional solution.

View Details6082 Marine Aluminum Tubes for Saltwater Exposure Resistant Boats

Advantages of 6082 marine aluminum tubes, specifically engineered for saltwater exposure resistant boats. Learn about their chemical composition, mechanical properties, tempering conditions, implementation standards, and why they are the optimal choice in

View Details

Leave a Message