Seamless Marine Aluminum Elbow for Emergency Ventilation Systems

In the demanding realm of maritime safety and engineering, emergency ventilation systems serve as a cornerstone for onboard operational security and crew welfare. At the heart of these critical systems is a pivotal yet often overlooked component—the seamless marine aluminum elbow. Beyond its simple appearance, this component ensures optimal airflow redirection under high-stress conditions, showcasing a sophisticated blend of material science and maritime engineering perfection.

The Functionality Landscape: Why Seamless Marine Aluminum Elbows Matter

Emergency ventilation systems on vessels must function flawlessly during maritime emergencies such as fires, hazardous gas leaks, or sudden inability to ventilate naturally. The seamless marine aluminum elbow facilitates smooth air or smoke directional changes within HVAC ducts or extracted airways aboard ships, reducing turbulent flow resistance and maintaining structural integrity.

Unlike flanged or welded counterparts, a seamless elbow eliminates weak points caused by joints which can become rupture spots under sudden pressure surges. This seamless nature assures uninterrupted airflow, bolstering rapid pressure equalization servicing emergency exhausts, thereby safeguarding occupiable spaces and critical equipment from smoke infiltration or suffocation hazards.

Technical Composition: Magnetic Intersection of Strength, Corrosion Resistance, and Weight

Marine aluminum alloys used for these elbows, commonly conforming to the 5052-H32 temper, play a dual role by combining mechanical durability with exceptional saltwater corrosion resistance. This temper indicates aluminum alloy strain-hardened (designated by ‘H32’), ensuring heightened tensile strength exceeding 27,000 psi—achieved without detrimental brittleness or heavy reinforcement.

The comprehensive chemical composition tailored for marine grade seamless elbows generally adheres to:

| Element | Percentage (%) |

|---|---|

| Aluminum (Al) | Balance (~97.25) |

| Magnesium (Mg) | 2.2 – 2.8 |

| Chromium (Cr) | 0.15 – 0.35 |

| Manganese (Mn) | ≤ 0.1 |

| Iron (Fe) | ≤ 0.4 |

| Copper (Cu) | ≤ 0.1 |

| Silicon (Si) | ≤ 0.25 |

| Zinc (Zn) | ≤ 0.1 |

The precise combination ensures the ideal milieu for marine environments, embodying stress-corrosion resistance essential for prolonged immersion in saline atmospheres, following classification guidelines by ASTM B209/B221.

Implementation Standards and Norms: Maritime Safety and Manufacturing Codex

Seamless marine aluminum elbows must rigidly meet or exceed standards like ABS (American Bureau of Shipping) Rules for Building and Classing Steel Vessels – effectively applied by analogy for aluminum alloys and ISO 15590-1 for welding of metallic tubular components used in pipelines (given the need for flawless piercing and bending without joining strips).

The product geometry typically follows angular measurements commonly 45°, 90°, and 180° bends with standardized wall thickness ranging from 2 mm to 6 mm to harmonize airflow with vessel duct diameter spanning from 2 inches to 24 inches or beyond. Seamless manufacturing achieves testament to metal integrity validated by non-destructive ultrasonic testing (NDT) or radiographic inspection (RT).

Alloy Tempering and Manufacturing Conditions for Optimal Performance

Manufacturing embraces control of:

- Heat treatments to stabilize temper H32 characteristics that permit malleability during bending and cold working while restricting grain growth.

- Clean rooms and dust-free environments during shaping to preserve surface finish critical in curbing corrosion rates.

- Precision mandrels and rollers for bending, preventing wrinkles or wall thinning faced by welded elbows.

- Post-fabrication anodizing or protective coatings whenever usage includes highly aggressive fire-smoke chemical exposure users like vessel engine rooms.

Captured Benefits Through a Unique Lens

Examined from an emergency preparedness perspective, the seamless aluminum elbow acts as a 'smart conduit tuner'—intelligently rerouting air volumes without compromising ductwork endurance or contributing to airflow resistance loss characterized as pressure drops in computational fluid dynamics (CFD) simulations aboard vessels.

Moreover, selecting marine-grade seamless aluminum friendly drivers keeps elbows lightweight—to optimize vessel weight such that fuel consumption remains combat efficient while maintaining compliance with maritime classification societies. The weight loss mirrored per actual component can eclipse 30% reduction against equivalent stainless steel elbows, turning overall structural cargo or ballasting system advantages.

Related Products

Custom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View DetailsMarine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

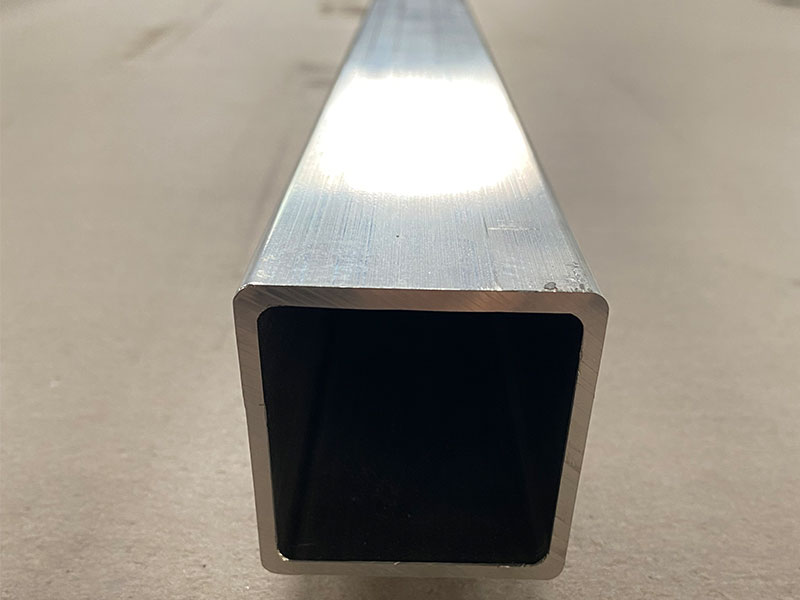

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsRelated Blog

Marine Aluminum Elbow for Combustion Air Supply Systems

In the demanding environment of marine vessels, reliable components contribute immensely to safety, efficiency, and longevity. Among such vital parts.

View DetailsAluminum Elbow for High Pressure Saltwater Pipelines on Ships

In modern shipbuilding and marine engineering, the integrity and durability of high pressure saltwater pipelines stand as a critical priority.

View DetailsMarine Aluminum Elbow for Dual Water/Fuel Transfer Pipelines

The Marine Aluminum Elbow designed for dual water/fuel transfer pipelines is a critical component in the maritime and offshore industries. Engineered specifically for vessels and offshore platforms.

View DetailsMarine Aluminum Elbow for Wastewater Filtration Systems

Durable, corrosion-resistant Marine Aluminum Elbow designed specifically for wastewater filtration systems. Engineered to meet rigorous marine standards, this elbow ensures optimal flow management and longevity in harsh saline and wastewater environments.

View Details5052 Marine Aluminum Round Tubes for Marine Applications

5052 Marine Aluminum Round Tubes are widely acclaimed within the marine industry for their excellent corrosion resistance, strength, and outstanding durability in harsh saltwater environments.

View DetailsMarine Aluminum Pipe Elbow for Shipbuilding

In the ever-evolving shipbuilding industry, the choice of materials plays a pivotal role in ensuring vessel performance, safety, and longevity.

View Details

Leave a Message