Marine aluminum 5083

Marine Aluminum 5083 is one of the most renowned aluminum alloys widely used in the marine industry. Its exceptional performance in harsh maritime environments, thanks to outstanding corrosion resistance, particularly from seawater and salt spray, has made it a top choice for shipbuilding, offshore platforms, and other marine structural applications.

Chemical Composition of Marine Aluminum 5083

The chemical make-up of 5083 alloy is carefully balanced to deliver superior corrosion resistance, strength, and weldability. Per the international standards such as ASTM B209 and EN 5083, the nominal chemical composition (% by weight) is as follows:

| Element | Min (%) | Max (%) |

|---|---|---|

| Aluminum (Al) | Balance | Balance |

| Magnesium (Mg) | 4.0 | 4.9 |

| Manganese (Mn) | 0.4 | 1.0 |

| Chromium (Cr) | 0.05 | 0.25 |

| Iron (Fe) | - | 0.4 |

| Silicon (Si) | - | 0.4 |

| Copper (Cu) | - | 0.1 |

| Zinc (Zn) | - | 0.25 |

| Titanium (Ti) | - | 0.15 |

| Others (Total) | - | 0.15 |

- Magnesium (4.0-4.9%): Major strengthening agent; enhances corrosion resistance, especially in seawater.

- Manganese (0.4-1.0%): Contributes to strength and grain structure refinement.

- Chromium (0.05-0.25%): Improves corrosion resistance by controlling grain boundary precipitation.

Mechanical Properties

Aluminum 5083 is recognized for its mechanical attributes, which ensure reliability and durability under marine operational stress.

| Property | Typical Value | Test Standard |

|---|---|---|

| Tensile Strength | 275 - 317 MPa | ASTM E8 |

| Yield Strength (0.2%) | 125 - 230 MPa | ASTM E8 |

| Elongation at Break | ≥12% | ASTM E8 |

| Hardness (Brinell) | 75 - 85 HBW | ASTM E10 |

| Density | 2.66 g/cm³ | - |

| Modulus of Elasticity | 70 GPa | ASTM E111 |

Values correlate to specific tempers such as O (annealed) or H116 (strain hardened and partially annealed).

Temper Conditions

The performance characteristics of 5083 vary based on temper. Common industrial tempers include:

| Temper | Description | Mechanical Characteristic Highlights |

|---|---|---|

| O | Fully annealed | Lower strength but highest ductility |

| H111 | Strain-hardened, minimal temp remit | Moderate strength, improved formability |

| H116 | Strain-hardened, cryogenically treated for maximum corrosion resistance | Common in marine vessels due to balanced strength and corrosion resistance |

| H321 | Strain-hardened and stabilized | High strength with excellent stress corrosion performance |

Implementation Standards & Certifications

To ensure quality and consistency, Marine Aluminum 5083 must meet several standards internationally recognized in marine and industrial structures:

- ASTM B209: Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate

- EN ISO 572-1: Aluminum and aluminum alloys — Chemical composition and form of wrought products — Part 1: Numerical Designation System

- ABS (American Bureau of Shipping): Approval for several thicknesses and product forms, ensuring marine safety

- DNV GL (Det Norske Veritas): Certifications for use in offshore engineering systems

Alloys certified under these siderules offer reliability for constructed hulls, decks, and hydrographic frames.

Corrosion Resistance Properties

One outstanding attribute of Marine Aluminum 5083 is its superior corrosion resistance:

- Excellent resistance to seawater, brine, and industrial chemicals found on ships.

- Superior oxidation protection enabling long service life in marine applications.

- Proven resistance against stress corrosion cracking and exfoliation, notably in tempers H116 and H321.

- Lower galvanic corrosion rates when in contact with stainless steel, zinc, or copper as compared to several other aluminum alloys.

Applications

Due to its extensive list of desirable features, Marine Aluminum 5083 is widely used in the following environments:

- Shipbuilding: Hulls, superstructures, decks, bulkheads

- Offshore Platforms: Structural frameworks and piping supports

- Military Vessels: Due to excellent ballistic resistance and weldability

- Yachts & Recreational Watercraft

- Cryogenic Tanks & Pressure Vessels except where higher fatigue resistance is critical

Welding & Fabrication Tips

- 5083 is highly weldable using TIG, MIG, and friction stir welding without compromising corrosion resistance.

- It is recommended to use filler alloys of matching compositions (commonly ER5356).

- Post-weld heat treatment is usually not required; nevertheless, controlled procedures minimize warping.

Related Products

Marine anodized aluminum sheets

Marine Anodized Aluminum Sheets start with premium marine-grade aluminum alloys such as 5000 and 6000 series (typically 5083, 5052, and 6061).

View DetailsMarine 5383 aluminum sheet

5383 aluminum is a strain-hardened, non-heat-treatable alloy from the 5xxx series primarily alloyed with magnesium. It exhibits a unique balance of corrosion resistance and mechanical properties particularly suited for marine applications.

View DetailsMarine 5052 aluminum sheet

Aluminum alloy 5052 is a non-heat-treatable, strain-hardened alloy with magnesium as the primary alloying element. It is designed to offer superior corrosion resistance in marine and saline environments, making it a dependable choice for components exposed directly to seawater or coastal atmospheric conditions.

View DetailsMarine Aluminum Tread Sheets

Marine Aluminum Tread Sheets are aluminum alloy plates featuring a raised surface pattern, commonly referred to as a tread design or diamond plate.

View DetailsMarine 5059 aluminum sheet

5059 aluminum alloy is a strain-hardened material with a unique addition of magnesium and chromium, which provides outstanding resistance to localized corrosion like pitting and stress corrosion cracking.

View DetailsMarine 5086 aluminum sheet

This product article provides an in-depth and comprehensive understanding of Marine 5086 Aluminum Sheets, including their chemical composition, mechanical properties, corrosion resistance, fabrication capabilities, and typical marine applications.

View DetailsRelated Blog

5052 5083 marine grade aluminium sheet for boat

Marine grade aluminium alloys 5052 and 5083 are among the most widely used non-heat-treatable alloys for shipbuilding, small vessels, and marine components. They combine good corrosion resistance in seawater, excellent weldability and formability.

View DetailsAntiCorrosion 5083 Aluminum Sheet for Marine

Superior corrosion resistance and high strength of AntiCorrosion 5083 Aluminum Sheets, specifically designed for marine applications. Learn detailed specifications, alloy tempering, mechanical properties, and implementation standards in this comprehensive

View DetailsAluminum Sheet for Boat 5083 H111 H112 H116 H32

The Aluminum Sheet 5083 series is notably recognized in marine and industrial applications, particularly aluminum sheets used for boat construction. Among the temper designations, H111, H112, H116.

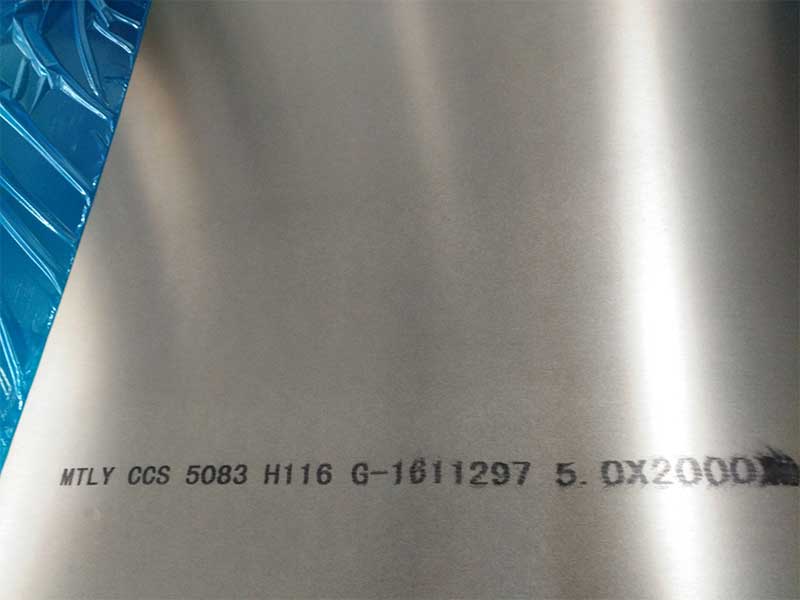

View DetailsAluminum sheet 5083 h116 with certificate of CCS for marine

High-performance Aluminum Sheet 5083 H116, certified by CCS for marine use. Explore its chemical properties, mechanical parameters, tempering conditions, and compliance standards making it ideal for marine environments.

View Details5083 aluminium marine grade 3.2 mm thick aluminium sheet

5083 Aluminium Marine Grade 3.2 mm Thick Aluminium Sheet: Unveiling Its Functional Excellence and Versatile ApplicationsIn the realm of marine engineering, material selection determines durability, safety, and performance.

View Details5052 5083 alloy 16 gauge aluminum sheet for boat building

5052 Aluminum Alloy5052 aluminum alloy is a non-heat treatable alloy known for its exceptional corrosion resistance, especially against saltwater, making it a popular choice for marine environments.

View Details

Leave a Message