5083 aluminium marine grade 3.2 mm thick aluminium sheet

5083 Aluminium Marine Grade 3.2 mm Thick Aluminium Sheet: Unveiling Its Functional Excellence and Versatile Applications

In the realm of marine engineering, material selection determines durability, safety, and performance. Among the many options, the 5083 aluminium marine grade 3.2 mm thick aluminium sheet emerges as a standout performer. Beyond just being a sheet of metal, it embodies unmatched strength, corrosion resistance, and workability specifically tailored for the rigorous marine environment.

5083 Marine Grade Aluminium: A Unique Alloy Composition

5083 aluminium is part of the 5xxx series aluminium alloys which are renowned for their excellent corrosion resistance—especially crucial in saline environments like oceans and seas. The alloy is predominantly magnesium-based (roughly 4-4.9%), which is a factor in bolstering the overall resistance against seawater corrosion. This makes 5083 particularly well-suited for maritime constructions. Additionally, it includes minor elements such as manganese and chromium to add strength and toughness without compromising ductility.

Working with 5083 aluminum sheet, specifically the 3.2mm thick marine grade, is a daily reality for me. We see a lot of it used in boat hulls and superstructures, and I’ve come to appreciate its unique properties. Its higher magnesium content compared to other aluminum alloys translates directly to superior corrosion resistance in saltwater environments – crucial for its intended application. However, this also means it's slightly less formable than some of the softer alloys we handle, requiring more precise tooling and techniques during fabrication. A common issue we encounter is ensuring consistent weld quality, as improper techniques can lead to porosity and compromise the structural integrity. Proper pre-cleaning and post-weld inspection are paramount for achieving reliable, long-lasting welds on this material.

Beyond the technical specs, I've noticed a trend. While its superior corrosion resistance is a huge selling point, customers are increasingly concerned about the total lifecycle cost. This means factors like the initial cost of the material, ease of fabrication, and long-term maintenance needs are all weighing heavily in their decisions. We're finding that providing detailed technical support and highlighting the long-term cost savings associated with 5083's durability is to convincing customers that the initial investment is worthwhile. It's not just about selling aluminum; it's about selling a solution that minimizes corrosion-related downtime and replacements over the lifespan of their marine vessel.

Chemical Composition of 5083 Aluminium Marine Grade (% Weight)

| Element | Typical Range |

|---|---|

| Magnesium (Mg) | 4.0 - 4.9 |

| Manganese (Mn) | 0.4 - 1.0 |

| Chromium (Cr) | 0.05 - 0.25 |

| Iron (Fe) | ≤ 0.4 |

| Silicon (Si) | ≤ 0.4 |

| Copper (Cu) | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.25 |

| Others | ≤ 0.15 |

| Aluminium (Al) | Balance |

This finely-tuned chemical matrix equips the 5083 sheet to withstand aggressive environmental conditions, mechanical stresses, and prolonged exposure to saltwater—functionalities demanded by marine applications.

3.2 mm Thickness: Balancing Strength and Flexibility

The specified thickness of 3.2 mm presents an optimal dimension for various marine usages. This thickness provides a sturdy structural profile for resistance against deformation while still maintaining a degree of flexibility necessary for forming complex shipparts or marine components without cracking or reducing integrity.

From plating small coastal boats to hull reinforcements for ferries, 3.2 mm thickness strikes a fine balance: resilient yet manageable, hefty enough for mechanical load and thin enough for adaptability. The size is versatile for customized applications, such as fabrication of bulkheads, decks, and superstructures.

Alloy Temper and Mechanical Properties

5083 aluminium comes primarily in the temper conditions H111 and H116 for marine standards, which refer to strength and strain-hardening mechanisms. The H116 temper, in particular, is internationally approved for ship building because it represents enhanced resistance to environmental cracking (stress corrosion cracking) alongside sustained mechanical strength:

| Property | Unit | Value (H116 Temper) |

|---|---|---|

| Ultimate Tensile Strength | MPa | 317 |

| Yield Strength | MPa | 228 |

| Elongation at Break | % | 12 |

| Hardness (Brinell) | HB | ~75 |

| Density | g/cm³ | 2.66 |

Parameters like high yield strength and notable elongation ensure this aluminium can bear substantial load without failure, making it suitable for dynamic marine environments.

Implementation Standards and Quality Assurance

Manufacture and testing of 5083 marine grade aluminium sheets generally comply with international standards such as:

- ISO 6361: Specification for wrought aluminium sheets and plates.

- ASTM B209: Specification for Aluminium and Aluminium-Alloy Sheet and Plate.

- AA (Aluminium Association) Grades: Specifications ensure chemical, mechanical, and thermal properties align perfectly with precise marine-item requirements.

- Class Displays: Aluminium often follows Lloyd’s Register or DNV GL standards detailing shipbuilding behaviors.

The 3.2 mm aluminium sheet typically undergoes fabrication, finishing, and quality assurance sequences including ultrasonic testing and corrosion resistance evaluations to certify seamless functioning in shipyards.

Functional Applications: Where Theory Meets Reality

The demand for 5083 3.2 mm aluminium sheets transcends general marine usage. applications include:

- Hull and Deck Construction: Giving ships a lightweight framework that combats rust fiercely compared to steel.

- Watertight Bulkheads and Internal Dividers: Reducing overall weight alongside enhanced compartmentalization safety.

- Boat Superstructures: Offering flexibility with weldability that’s critical for joined sections exposed to forces like waves and mechanical impact.

- Oil & Gas Marine Structures: Offshore platforms exposed to specialized high-stress conditions.

- Specialized Transportation Vessels: Eg., high-speed craft, hovercraft, and aluminum room modules on marine research vessels

Unique Technical Advantage: Heat Treatment Non-Requirement

Most marine aluminum grades require at least some heat treatment. However, 5083's remarkable capability is that in H116 or H111 temper, it achieves its mechanical and corrosion resistance properties mostly through strain hardening without extensive solution heat treatments. Consequently, manufacturers reduce fabrication costs and simplify production timelines while adhering to strict quality standards, ensuring quicker deployment in projects.

Related Products

Marine 5383 aluminum sheet

5383 aluminum is a strain-hardened, non-heat-treatable alloy from the 5xxx series primarily alloyed with magnesium. It exhibits a unique balance of corrosion resistance and mechanical properties particularly suited for marine applications.

View DetailsMarine Aluminum Tread Sheets

Marine Aluminum Tread Sheets are aluminum alloy plates featuring a raised surface pattern, commonly referred to as a tread design or diamond plate.

View DetailsMarine 5086 aluminum sheet

This product article provides an in-depth and comprehensive understanding of Marine 5086 Aluminum Sheets, including their chemical composition, mechanical properties, corrosion resistance, fabrication capabilities, and typical marine applications.

View DetailsMarine 5052 aluminum sheet

Aluminum alloy 5052 is a non-heat-treatable, strain-hardened alloy with magnesium as the primary alloying element. It is designed to offer superior corrosion resistance in marine and saline environments, making it a dependable choice for components exposed directly to seawater or coastal atmospheric conditions.

View DetailsMarine 5083 aluminum sheet

Aluminum alloy 5083 is a non-heat-treatable alloy primarily composed of magnesium and trace elements that deliver outstanding protection against corrosion, particularly in seawater and saline atmospheres.

View DetailsMarine 5059 aluminum sheet

5059 aluminum alloy is a strain-hardened material with a unique addition of magnesium and chromium, which provides outstanding resistance to localized corrosion like pitting and stress corrosion cracking.

View DetailsRelated Blog

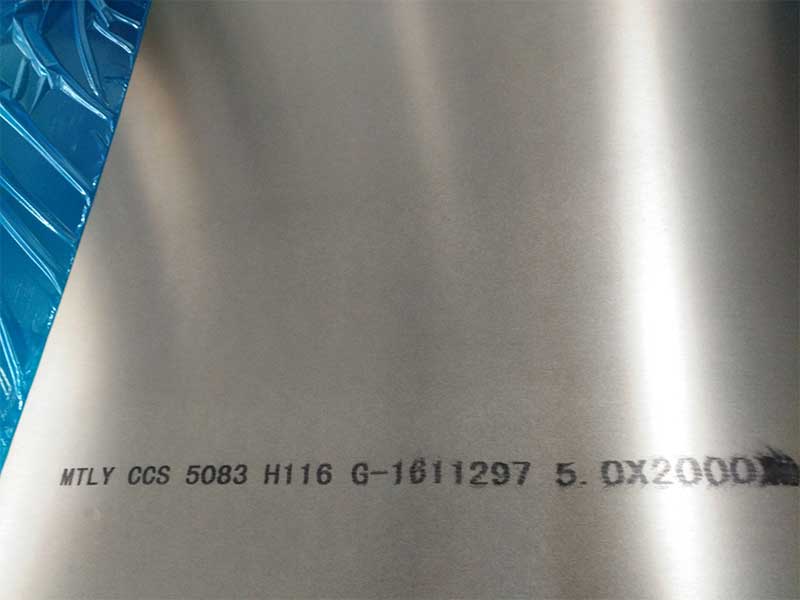

Aluminum sheet 5083 h116 with certificate of CCS for marine

High-performance Aluminum Sheet 5083 H116, certified by CCS for marine use. Explore its chemical properties, mechanical parameters, tempering conditions, and compliance standards making it ideal for marine environments.

View DetailsAluminum Sheet A5083 H116 H321 for Marine Ship

Aluminum Sheet A5083 in tempers H116 and H321 is a primary material choice for manufacturing marine vessels and shipbuilding components. It combines exceptional mechanical properties with strong corrosion resistance.

View Details5052 5083 alloy 16 gauge aluminum sheet for boat building

5052 Aluminum Alloy5052 aluminum alloy is a non-heat treatable alloy known for its exceptional corrosion resistance, especially against saltwater, making it a popular choice for marine environments.

View Details5083 aluminium marine grade 3.2 mm thick aluminium sheet

5083 Aluminium Marine Grade 3.2 mm Thick Aluminium Sheet: Unveiling Its Functional Excellence and Versatile ApplicationsIn the realm of marine engineering, material selection determines durability, safety, and performance.

View DetailsAluminum Sheet for Boat 5083 H111 H112 H116 H32

The Aluminum Sheet 5083 series is notably recognized in marine and industrial applications, particularly aluminum sheets used for boat construction. Among the temper designations, H111, H112, H116.

View DetailsMarine aluminum 5083

In-depth insights into Marine Aluminum 5083, its chemical composition, mechanical properties, temper conditions, and why it stands as the premier alloy for marine and offshore structural applications.

View Details

Leave a Message