3mm 5083 Marine Grade Aluminum Plate For Ship building

In the demanding world of shipbuilding, materials that combine strength, durability, and corrosion resistance are essential to construct vessels that can withstand harsh marine environments. Among these materials, the 3mm 5083 marine grade aluminum plate stands out as a premier choice, offering an exceptional balance of technical properties and practical functionality.

Why 3mm 5083 Marine Grade Aluminum Plate?

The 5083 aluminium alloy is renowned for its high magnesium content, contributing to outstanding corrosion resistance, particularly in saltwater environments. In shipbuilding, where a thin yet robust decking or hull plating is critical, the 3mm thickness option offers an optimal solution. It provides adequate mechanical strength while enabling manufacuturers to reduce vessel weight — a crucial factor that improves fuel efficiency, speed, and payload capacity.

Working with 3mm 5083 marine grade aluminum plate for shipbuilding highlights its excellent weldability and formability, crucial for complex hull sections and other intricate components. However, a common challenge is achieving consistent weld quality, especially in thicker sections. Preheating is essential to mitigate cracking and ensure proper fusion, and the selection of the appropriate welding parameters (current, voltage, speed) is critical depending on the joint design and desired mechanical properties. We've seen instances where improper welding techniques led to porosity or incomplete penetration, necessitating rework and impacting production schedules. Careful operator training and stringent quality control, including radiographic testing (RT) for critical welds, are paramount to prevent these issues and ensure the structural integrity of the final product.

Beyond welding, the inherent workability of 5083 aluminum allows for efficient fabrication, significantly reducing lead times compared to steel alternatives. However, its susceptibility to scratching and surface marring during handling and processing demands careful attention. Implementing protective measures, such as using appropriate tooling and handling procedures, is crucial to maintain the surface quality and prevent corrosion. Furthermore, the selection of appropriate coatings and surface treatments, tailored to the specific marine environment and intended application, plays a vital role in maximizing the longevity and corrosion resistance of the final shipbuilding component. We've found that combining proper surface preparation with high-quality coatings significantly extends the service life and reduces maintenance costs.

Applications of 3mm 5083 Marine Grade Aluminum Plate in Shipbuilding

- Hull and superstructure construction: Lightweight hull sections that resist corrosion in seawater extend service life and reduce maintenance needs.

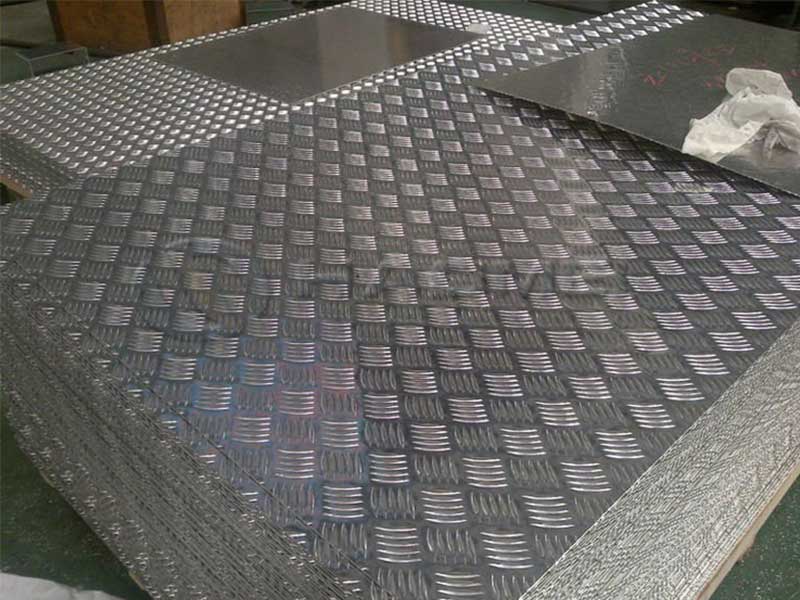

- Deck plates and flooring: Thinner plates allow easy fabrication of decks with good mechanical resistance, improving worker safety and vessel longevity.

- Interior bulkheads: Structural reinforcements within compartments benefit from this alloy’s strength-to-weight ratio.

- Marine equipment fabrication: Lifeboat frames, cranes, rails, and fewer components leverage the material for its weldability and toughness.

Technical Details and Mechanical Properties

| Property | Value |

|---|---|

| Thickness | 3mm |

| Alloy Grade | 5083 Maritime Grade |

| Temper | H111/H116 (Non-heat treatable versions) |

| Density | 2.66 g/cm³ |

| Tensile Strength (MPa) | 275-350 MPa (depending on temper) |

| Yield Strength (MPa) | 125-230 MPa |

| Elongation | 12-20% |

| Hardness | ~75 HB |

| Corrosion Resistance | Exceptional in seawater |

| Welding | Excellent weldability |

Alloy Temper and Its Importance

5083 alloy is a non-heat-treatable alloy, meaning that it derives its mechanical properties primarily from strain hardening or cold working with various tempers such as H111, H116, and H321 used for specific marine applications:

- H111: Slightly work-hardened, used where moderate strength is required.

- H116/H321: Specially processed for maximum corrosion resistance in unsheltered (seawater) environments and has optimized weldability and strength results. This temper is typically preferred in marine industries to combat stress corrosion cracking.

Chemical Properties Table of 5083 Aluminum Alloy

| Element | Percentage (%) |

|---|---|

| Aluminum (Al) | Balance (Aluminum Small Trace Impurities) |

| Magnesium (Mg) | 4.0 - 4.9 |

| Manganese (Mn) | 0.4 - 1.0 |

| Iron (Fe) | ≤ 0.4 |

| Copper (Cu) | ≤ 0.1 |

| Silicon (Si) | ≤ 0.4 |

| Chromium (Cr) | 0.05 - 0.25 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 |

Implementation Standards and Compliance

The marine grade 5083 aluminum plates conform to multiple international standards, which ensures their broad acceptance and reliability in shipbuilding applications.

- ASTM B928 / B928M: Specification covering high magnesium aluminum alloy plate and sheet primarily intended for marine use.

- EN 485-2 / EN 573-3: Relevant European standards relating to the mechanical testing and chemical composition of aluminum alloys.

- ABS (American Bureau of Shipping) and ISO 9001: Commonly included in manufacturing sites’ certifications indicating consistent quality and suitability for safety standards in maritime equipment.

The unique material properties of 5083 aluminum plates at 3mm thickness perfectly complement the rigorous requirements of shipbuilding. This marine-grade plate combines the excellent corrosion resistance brought by magnesium-rich alloying with enough thickness to maintain structural integrity without adding excessive weight. Enhanced by standard tempers like H116, this aluminium alloy facilitates reliable welding, excellent formability, and notable mechanical strength in salty seas.

Whether constructing the outer hull of fast ferries, welding internal bulkheads, or fabricating deck components, selecting this marine aluminum grade guarantees extended vessel longevity, less corrosion-related downtime, and efficient operational performance. IND-aluminium providers who understand specific ship classification requirements consistently use and recommend 5083 marine aluminum plates in this size benchmark, earning their trust in demanding maritime engineering projects.

For engineers and stakeholders in the shipping and offshore industry, opting for the 3mm 5083 marine grade aluminum plate keeps modern ship materials technology at the forefront — reassuring quality, performance, and sustainability are met with every nautical application.

Related Products

Marine 5086 aluminum plate

5086 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys. Its hallmark is a high magnesium content—generally between 4.0% and 4.9%—which delivers enhanced corrosion resistance, particularly against saltwater and marine atmospheric conditions.

View DetailsMarine 5383 aluminum plate

The 5383 aluminum alloy belongs to the 5xxx series of aluminum-magnesium alloys known for remarkable resistance to marine corrosion and high strength.

View DetailsMarine 5083 aluminum plate

Marine 5083 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys and is classified as a non-heat-treatable alloy. Its high magnesium content (typically 4.0–4.9%) enhances its corrosion resistance, especially against seawater-related degradation such as pitting and stress corrosion cracking.

View DetailsMarine 5059 aluminum plate

Marine 5059 Aluminum Plate is distinguished by its high magnesium content and carefully balanced alloying elements, designed to maximize strength without compromising corrosion resistance.

View DetailsMarine heavy duty aluminum plate

Marine Heavy Duty Aluminum Plates Sheets generally refer to thick aluminum alloy plates and heavy gauge sheets produced from marine-grade alloys such as 5083, 5086, 5059, and 5383.

View DetailsMarine 5052 aluminum plate

Marine 5052 Aluminum Plate is noted for its exceptional resistance to corrosion caused by seawater, salt spray, and marine atmospheres.

View DetailsRelated Blog

Marine Grade 5083, 5082 Aluminum Alloy Sheet Plate

When it comes to materials that perform exceptionally under the harsh conditions of marine environments, Marine Grade aluminum alloys like 5083 and 5082 hold a revered place in the industry’s toolkit.

View Details7.5 mm marine grade 5083 h16 h22 aluminium sheet plate

Marine environments are notoriously harsh, subjecting materials to saltwater corrosion, mechanical stress, and temperature fluctuations. Among the materials engineered to withstand these conditions, 7.

View DetailsMarine Grade Aluminum Plate 5083

When it comes to building robust, durable, and corrosion-resistant marine vessels and offshore structures, Marine Grade Aluminum Plate 5083 stands as a premier choice in the industry.

View DetailsMarine Aluminum Alloy Plate 5052 5083 6061

Marine environments pose extreme challenges—constant exposure to saltwater corrosion, mechanical stresses, and environmental fluctuations demand materials that combine strength, durability, and corrosion resistance.

View Details5083 H111 H112 Aluminium Alloy plate untuk Boat

Temukan keunggulan pelat aluminium 5083 H111 dan H112 untuk aplikasi kapal. Pelajari spesifikasi teknis, sifat kimia, tempering, standar implementasi, serta alasan utama pemilihannya di industri laut.

View DetailsMarine Grade Plate Aluminum Sheet 5083 O H116

When it comes to marine construction and offshore applications, selecting the right material is crucial. Marine Grade Aluminum Plate 5083 O H116 stands out as a top-tier solution, blending excellent mechanical properties, corrosion resistance.

View Details

Leave a Message