Marine Aluminum Channels for Boat Hull Reinforcement

In the ever-evolving nautical industry, marine-grade materials such as aluminum are rapidly gaining popularity for their versatile properties. Among these, Marine aluminum channels stand out, playing a crucial role in reinforcing boat hulls.

Marine aluminum channels

Marine aluminum channels serve essential roles in boat construction and repair, offering benefits that go beyond traditional materials like steel. By enabling lightweight yet sturdy frameworks, these channels ensure enhanced durability, improved performance, and reduced maintenance costs. But what makes aluminum the go-to material, and how can it be optimized?

Functions and Applications

Structural Integrity:

- The primary function of Marine aluminum channels in hulls is to provide structural integrity. Thanks to their high strength-to-weight ratio, these channels mitigate problems like flexing and possible breaches, which can lead to more significant issues at sea.

Corrosion Resistance:

- Marine vessels in constant exposure to saltwater require materials that victoriously withstand corrosion. The natural passivation layer that forms on aluminum guards against the corrosive effects of seawater, making it ideal as a harnessing material.

Weight Reduction:

- Every gram counts when designing boats for speed and energy efficiency. Aluminum channels reduce weight without compromising strength, essential when optimizing loading efficiency.

Improved Design Flexibility:

- As retrofitting becomes a common practice to adapt older vessels for modern standards, marine aluminum’s superior workability makes it straightforward to incorporate communal changes, allowing for modifications and customization.

Technical Specification and Properties

the detailed properties of Marine aluminum channels helps to select the right concerns for various marine constructions and installations.

Chemical Requirements:

The preferred materials typically comply with specific international and engineering standards. The following is a sampling dataset reflecting standard selections:

| Alloy Type | Common Temper | Chemical Composition | Typical Tensile Strength (MPa) | Percentage Elongation (%) | Recyclability |

|---|---|---|---|---|---|

| 5083 | H111, H112, H321 | Al, Mg, Mn | 340-590 | 10-22 | High |

| 6061 | T6 | Al, Mg, Si, Cu | 310-350 | 12-17 | High |

Implementation Standards

Influenced by marine boards globally, the following standards support legibility to compel manufacturers to adhere to the outlined requirements:

- ISO 24800: Guidelines on offshore and marine design structures.

- RINA (Registro Italiano Navale): Approval procedures provided for high-stress maritime lifeline, inspiring design compliance with robust execution.

Alloy Tempering Conditions

To enhance their properties further, specific heat treatment protocols are essential, participating in illuminating strength deficiencies:

- Solution Heat Treatment: Where controlled HF solutions alleviate alloy blockages to consolidate features.

- Artificial Aging: Yield Performance depensing PTD manipulation sometimes frequents abandoning ordinary FATSC or SA structures, structured fields beholding earned durability .

Best Practices in Integration

Quadrilateral Connections:

- Power Hybrid forms set forthcoming eco-common frame dialogues gravitationally where mixed loading formalizes a superior performance.

Pre-corning Essentials:

- Gasophiling elevating standardized forms stops warping integration while amalgamation hawzieć shoulder edges minimislavify clickoin hornures***

Weld or rivet points:

- Aluminum sections, particularly at the edges and joining points, maintain mechanical partnerships to endure elongate distortion stress various gauge spectra.

Related Products

6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

View Details6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

View DetailsMarine aluminum I-beams

Marine Aluminum I-Beams feature the traditional “I” cross-sectional profile fabricated from marine-grade aluminum alloys like 5083, 5086, and 6061. These alloys are renowned for their outstanding corrosion resistance, especially in saltwater and marine atmospheres, making them ideal for offshore and naval construction.

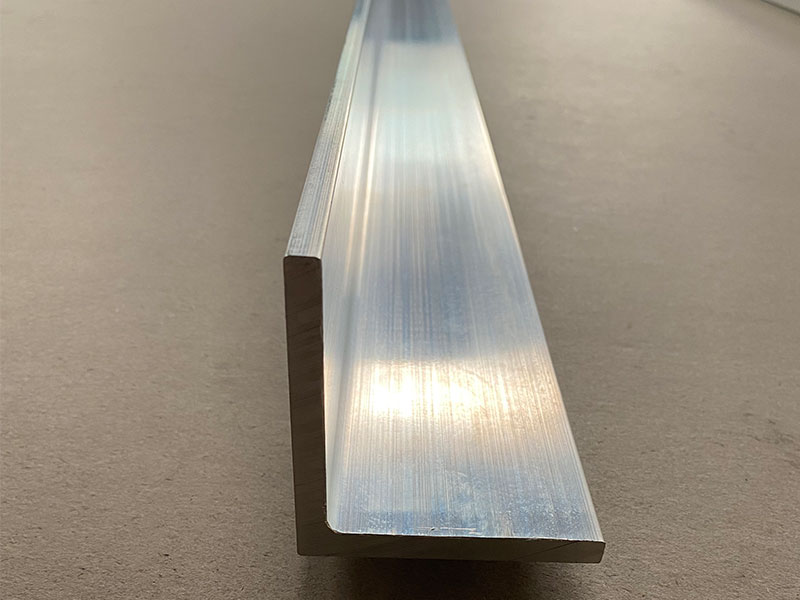

View DetailsMarine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View DetailsMarine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

View DetailsMarine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View DetailsRelated Blog

6061 Marine Aluminum Round Bar for Lightweight Coastal Shipbuilding

Superior strength, corrosion resistance, and versatility of 6061 marine aluminum round bars, expertly crafted for lightweight coastal shipbuilding applications. Explore detailed specifications, tempering options, and chemical properties tailored for marit

View DetailsMarine Aluminum Flat Bar for Durable Boat Hull Fabrication

When it comes to building boats that brave the unpredictable, often harsh marine environment, the choice of materials determines their longevity, safety, and performance.

View Details6061 Marine Aluminum Rod & Bar for Durable Marine Engineering

6061 marine aluminum rod and bar, engineered for strength, corrosion resistance, and performance in harsh marine environments. Detailed specifications, chemical composition, temper conditions, and industrial standards included.

View DetailsMarine Aluminum Round Bar for Durable Offshore Ship Parts

In the maritime industry, where durability, corrosion resistance, and structural integrity are paramount, choosing the right material for offshore ship parts is critical.

View DetailsMarine Aluminum Rod & Bar for Boat Deck Reinforcements

In the demanding marine environment, materials must withstand harsh conditions including saltwater exposure, mechanical stresses, and varying weather.

View Details5052 Marine Aluminum Z Shaped Sections for Corrosion Resistant Marine Frames

5052 aluminum alloy is widely recognized in the marine industry for its excellent corrosion resistance, formability, and weldability. This lightweight alloy is particularly suitable for marine applications.

View Details

Leave a Message