Marine Aluminum Elbow for Pressurized Water Systems on Ships

Marine aluminum elbows are critical components in the piping systems aboard ships, particularly within pressurized water supply lines. These fittings are designed to allow a smooth change of direction in piping layout, typically at 45° or 90°, without compromising mechanical integrity or further increasing system stress. Our Marine Aluminum Elbow series meets the stringent requirements of naval architecture and maritime engineering, promising longevity, light weight, and exceptional performance in harsh sea environments.

Material Specifications & Chemical Composition

Our marine aluminum elbows are manufactured from high-quality alloys categorized under the widely accepted marine aluminum grades such as 5083-H116 and 6061-T6. These alloys provide balanced strength and corrosion resistance, essential for saltwater exposure.

| Alloy | Major Alloying Elements (wt%) | Standards Compliance |

|---|---|---|

| 5083-H116 | Al, Mg (4.0-4.9), Mn (0.4-1.0), Fe (0.4 max) | IMO RESOLUTION MSC.215(82), ASTM B928 |

| 6061-T6 | Al, Mg (0.8-1.2), Si (0.4-0.8), Fe (0.7 max) | ASTM B241, ISO 6362 |

Engineering Parameters

| Parameter | Value / Range |

|---|---|

| Elbow Angles | 45°, 90° standard options |

| Pressure Rating | Up to 50 bar (725 psi) |

| Temperature Operating Range | -40°C to 120°C |

| Wall Thickness | 3mm to 10mm depending on size |

| Standard Pipe Sizes Available | DN15 to DN100 (1/2" to 4") |

| Surface Treatment | Marine-grade anodized or painted |

| Joining Methods | TIG/MIG welding or Mechanical Flanged |

| Weight Reduction | Up to 40% less than steel carcass |

Implementation Standards & Certification

To guarantee end-product reliability and safety onboard sea vessels, our Marine Aluminum Elbow undergoes rigorous testing and quality assurance processes, complying with the following industry standards:

- IMO MSC.215(82): International Maritime Organization criterion for materials and fabrication.

- ABS (American Bureau of Shipping): Certification ensures mechanical characteristics satisfy maritime vessel class requirements.

- ASTM B928 / B241: Aluminium alloy pipes and fittings standards pertinent to marine chemical composition and structural integrity.

- ISO 6362: Standards for aluminum tubes and fittings used in ships.

Alloy Tempering and Mechanical Properties

Different tunings (tempers) of aluminum alloys impact mechanical strength and flexibility. Typical temper states used in marine aluminum elbows include:

| Alloy | Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Corrosion Resistance |

|---|---|---|---|---|---|

| 5083 | H116 | 275-310 | 125-215 | ~12 | Excellent resistance to seawater corrosion |

| 6061 | T6 | 290-310 | 240-270 | 8-10 | Good corrosion resistance; anodized finish recommended |

Advantages of Marine Aluminum Elbow in Ship Systems

- Corrosion Resistance: Alloy chemistry provides excellent stiffness and prevents saltwater-induced aging.

- Lightweight: Less dense than steel, aluminum elbows contribute to considerable weight savings in ship superstructures.

- Reduced Maintenance: High durability minimizing failure and maintenance turnout.

- Ease of Installation: Superior weldability and machinability with standard stainless fastener compatibility.

- Thermal Conductivity: Enables reduced thermal build-up in pressurized systems, beneficial for fluid handling efficiency.

Typical Applications

- Freshwater and sea water cooling systems on ships and offshore platforms.

- Fire fighting water piping circuits where corrosion resistance and system integrity are critical.

- HVAC chilled water systems on marine vessels subject to cyclic temperature fluctuations.

- Evaporator feed lines in desalination plants onboard ships.

Related Products

6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsMarine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

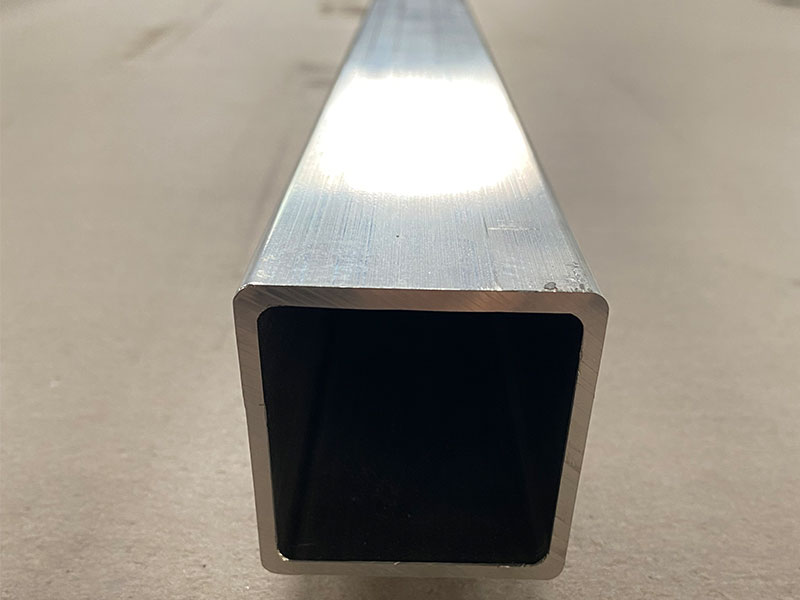

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsRelated Blog

Marine Aluminum Pipe Elbow for Seawater Reverse Osmosis Units

In the realm of modern water treatment, Seawater Reverse Osmosis (SWRO) units stand as a vital technology for converting seawater into potable water. components within these systems must withstand harsh marine environments, high pressure.

View DetailsMarine Aluminum Elbow for Wastewater Filtration Systems

Durable, corrosion-resistant Marine Aluminum Elbow designed specifically for wastewater filtration systems. Engineered to meet rigorous marine standards, this elbow ensures optimal flow management and longevity in harsh saline and wastewater environments.

View Details5052 Marine Aluminum Round Tubes for Marine Applications

5052 Marine Aluminum Round Tubes are widely acclaimed within the marine industry for their excellent corrosion resistance, strength, and outstanding durability in harsh saltwater environments.

View DetailsCorrosion Resistant Marine Aluminum Elbow Fittings

When we think of marine infrastructure—ships, offshore rigs, and dockside installations—durability under harsh, corrosive environments is paramount. Among the various components, elbow fittings play a critical role in fluid transport systems, en.

View DetailsCorrosion Resistant Aluminum Pipe Elbow for Offshore Platforms

In the challenging conditions of offshore platforms, where exposure to harsh saline water, high pressure, and fluctuating temperatures is constant, choosing the right piping components can make or break operational efficiency.

View Details5083 Marine Aluminum Tubes for Boat Building and Fabrication

In the demanding environment of marine vessel construction and fabrication, the selection of high-quality materials is crucial for ensuring durability, safety, and superior performance.

View Details

Leave a Message