Aluminum Pipe Elbow for Marine Waste Water Systems

Aluminum Pipe Elbow for Marine Waste Water Systems: A Focused Technical Guide

In modern shipbuilding and offshore platforms, the humble aluminum pipe elbow is doing a lot more work than most people realize—especially in marine waste water systems. It is not just a bent piece of metal; it is a carefully engineered flow-control component that balances corrosion resistance, weight, weldability, hygiene, and lifecycle cost in one compact geometry.

Below is a concise, technically grounded look at aluminum pipe elbows from the perspective of how and why they work in marine gray and black water systems, what parameters matter, and how alloy and temper choices influence performance.

How the Elbow Shapes Waste Water Flow

In waste water lines on ships and offshore structures, elbows are the “traffic directors” of the pipeline. Their primary functions include:

- Guiding flow direction while limiting pressure loss

- Reducing turbulence that can cause erosion and noise

- Minimizing stagnation pockets where waste can settle or cause odor

- Connecting dissimilar section layouts while maintaining system integrity

Unlike industrial elbows for high-pressure steam or chemicals, marine waste water elbows are often optimized around:

- Moderate-pressure flow, typically under 10 bar

- Strong corrosion resistance to chloride-rich seawater atmosphere

- Resistance to intermittent internal exposure to organic acids, detergents, salts, and cleaning chemicals

- Low total system weight to improve vessel efficiency and stability

A well-designed aluminum elbow manages these demands by combining the right curvature (commonly long-radius), precise wall thickness, and a marine-grade aluminum alloy specifically suited for harsh, saline environments.

Why Aluminum for Marine Waste Water Systems

From a marine engineering standpoint, aluminum pipe elbows are chosen over traditional steel or cast iron alternatives for several reasons:

- Low weight: Drastic weight savings compared to steel, supporting better fuel efficiency and increased payload capacity.

- Corrosion resistance: Marine alloys form a stable, self-healing oxide layer that resists pitting and general corrosion.

- Fabrication flexibility: Excellent weldability allows elbows to be integrated into complex, custom piping layouts aboard ships and platforms.

- Lower maintenance: Reduced need for heavy protective coatings and extended service intervals in non-abrasive waste water lines.

In gray water, galley drains, shower and laundry lines, and certain black water sections away from highly abrasive or solids-heavy zones, aluminum elbows can provide a durable and cost-effective solution.

Standards and Implementation Requirements

Marine aluminum pipe elbows typically align with a blend of marine, piping, and material standards. Depending on the shipyard and classification society, you may see references to:

- Aluminum material standards such as ASTM B241/B241M and EN 573 / EN 485 for seamless and wrought aluminum alloy pipes and fittings.

- Marine and offshore rules from classification societies like DNV, ABS, LR, BV, CCS, etc., specifying acceptable alloys, wall thickness, and corrosion allowances.

- Welding procedure standards such as ISO 15607, ISO 15614, or ASME IX for weld qualification of aluminum piping systems.

- Dimensional and pressure classification guidelines similar to ASME B16.9 concepts but adapted to aluminum and the lower pressures typical of waste water service.

Implementation standards generally demand:

- Non-destructive testing (NDT) for welds and sometimes for the elbows themselves (visual inspection, dye penetrant, and, where needed, radiography or ultrasonic).

- Surface preparations suitable for marine coatings when elbows are installed in exposed or splash zones.

- Electrical bonding and, where necessary, isolation from copper-containing alloys to mitigate galvanic corrosion.

Alloy and Temper: The Heart of Performance

For marine waste water elbows, alloy selection is about balancing corrosion resistance, mechanical strength, and fabrication behavior. Common families include:

- 5xxx series (Al-Mg): Strong candidates for marine use thanks to good seawater corrosion resistance and weldability. Alloys like 5083 and 5052 are classics in marine structures.

- 6xxx series (Al-Mg-Si): Frequently used for piping and fittings due to good extrudability, sufficient strength, and acceptable marine performance, especially when not directly immersed in seawater.

Typical alloys for aluminum pipe elbows in marine waste water systems might include:

- 5083-O / 5083-H111: Excellent corrosion resistance, good toughness, low to medium strength but highly reliable in marine atmospheres.

- 6061-T6 / 6082-T6: Higher strength, good machinability and shape stability, commonly used when elbows are part of more structurally loaded systems or require precise geometry. Shielding from direct seawater immersion and managing galvanic couples is crucial.

Tempering defines mechanical behavior:

- O (annealed): Highest ductility, easiest to form and bend, lower strength; good for elbows that may need tight bending or cold-forming.

- H111: Slightly strain-hardened, subtle increase in strength while maintaining good formability.

- T6: Solution heat-treated and artificially aged; significantly higher strength and hardness, best for precision fittings but somewhat less forgiving in severe cold-forming operations.

Selecting an alloy-temper combination should be based on:

- System pressure and mechanical loads

- Expected temperature range onboard

- Corrosive severity (internal media + external environment)

- Required fabrication processes (bending, welding, machining)

Typical Parameters for Marine Aluminum Pipe Elbows

Common technical parameters to define during specification of aluminum pipe elbows for marine waste water use include:

- Nominal diameter: Often DN 25–DN 300 for gray and black water lines, with larger sizes on passenger or offshore units.

- Wall thickness: Sized according to internal pressure, mechanical loads, and corrosion allowance; often in the range of 2–10 mm for low to moderate pressure systems.

- Bend radius: Long-radius elbows (standard centerline radius about 1.5D) preferred to minimize pressure loss, reduce risk of clogging, and ease cleaning.

- Angle: Typical angles are 45° and 90°, with custom angles for confined machinery spaces and complex hull geometries.

- End connections: Butt-weld ends are most common; flanged or grooved ends may be used in modular systems or where frequent disassembly is expected.

Each of these parameters ties back to classification rules and yard-specific standards, ensuring compatibility with valves, tees, reducers, and pumps in the same line.

Chemical Composition and Corrosion Behavior

chemical composition helps predict in-service behavior. Below is an indicative composition table for two common marine-grade aluminum alloys used in elbows:

Typical Chemical Composition (wt%)

| Element | 5083 (Al-Mg) | 6061 (Al-Mg-Si) |

|---|---|---|

| Aluminum (Al) | Balance | Balance |

| Magnesium (Mg) | 4.0–4.9 | 0.8–1.2 |

| Silicon (Si) | ≤ 0.40 | 0.40–0.80 |

| Manganese (Mn) | 0.40–1.0 | ≤ 0.15 |

| Iron (Fe) | ≤ 0.40 | ≤ 0.70 |

| Copper (Cu) | ≤ 0.10 | 0.15–0.40 |

| Chromium (Cr) | 0.05–0.25 | 0.04–0.35 |

| Zinc (Zn) | ≤ 0.25 | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 | ≤ 0.15 |

| Others (each) | ≤ 0.05 | ≤ 0.05 |

| Others (total) | ≤ 0.15 | ≤ 0.15 |

corrosion-related insights:

- Magnesium in 5xxx alloys promotes good general and pitting corrosion resistance in chloride environments, making 5083 suited to marine atmospheres and occasional seawater contact.

- Controlled levels of copper in 6061 improve strength and machinability but require careful avoidance of direct immersion in seawater without proper protection, due to higher galvanic potential.

- Chromium and manganese refine grain structure and enhance corrosion resistance and toughness, especially important in welded elbows.

Practical Application in Marine Waste Water Lines

In a typical vessel waste water system, aluminum pipe elbows are used in:

- Gravity-driven gray water drains from cabins, laundries, and galleys, where internal pressure is modest but space is tight.

- Pumped transfer lines between collection tanks, treatment units, and discharge points.

- Vent and overflow lines where low weight and corrosion resistance matter more than high mechanical strength.

Designers position aluminum elbows to maintain self-cleaning velocities in inclined runs, reduce the risk of blockages at changes of direction, and keep vibration and noise from pumps and machinery to a minimum. When combined with compatible aluminum or lined valves and flanges, the entire run becomes lighter and easier to support on brackets and hangers.

Coatings and insulation may be applied to elbows where they pass through living spaces or near heat sources, and dielectric spacers are used when transitioning to stainless or other metals to control galvanic effects.

Bringing It Together: A System-Level View

Looking at aluminum pipe elbows solely as fittings misses the bigger picture: they are nodes in a marine waste water network, where hydrodynamics, corrosion science, structural engineering, and onboard logistics converge.

The right alloy and temper provide corrosion resistance and mechanical reliability. Proper curvature and wall thickness keep the system efficient and quiet. Compliance with marine and material standards ensures longevity and safety.

For shipbuilders, owners, and system designers aiming to reduce weight and lifetime maintenance in gray and black water systems, specifying marine-grade aluminum elbows with well-defined parameters and alloy-temper combinations is a practical, technically robust path forward.

Related Products

6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

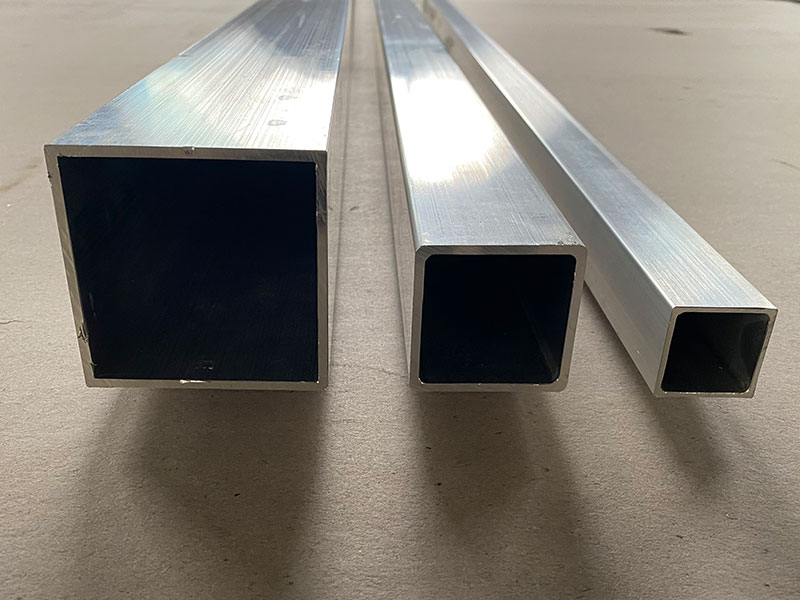

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsMarine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View DetailsRelated Blog

5083 Marine Aluminum Tubes for Offshore Oil and Gas Platforms

5083 marine aluminum tubes are widely used in offshore oil and gas platform structures where a combination of high strength, exceptional corrosion resistance and good weldability is required.

View Details5052 Marine Aluminum Tubes for Boat and Ship Building

Marine aluminum has proven to be an ideal material for boat and ship building due to its property of being lightweight, corrosion-resistant, and high strength. Among the various alloys available.

View DetailsMarine Aluminum Pipe Elbow for Desalination Plant Connections

In modern desalination plants, the choice of piping components is critical to ensuring efficiency, longevity, and resistance to harsh marine environments.

View DetailsCustom Made Marine Aluminum Elbow for Offshore Installations

Custom made marine aluminum elbows are corrosion‑resistant, lightweight, and high‑strength fittings engineered for offshore installations, topside piping, and subsea support systems.

View Details6082 Marine Aluminum Square Tubes for Corrosion Resistant Projects

When it comes to constructing structures that demand impeccable resistance to corrosion in harsh marine environments, 6082 marine aluminum square tubes is know as an industry favorite.

View DetailsMarine Aluminum Tubes for Nautical Equipment Manufacturing

Marine aluminum tubes stand at the forefront of nautical equipment manufacturing due to their exceptional range of properties, which make them indispensable in the marine industry.

View Details

Leave a Message