Marine Aluminum Flat Bar for Offshore Platform Fabrication

Marine Aluminum Flat Bar for Offshore Platform Fabrication: A Comprehensive Guide to Functions, Applications, and Technical Insights

In the demanding environment of offshore platform fabrication, material selection is paramount to ensure durability, corrosion resistance, and structural integrity. Marine aluminum flat bars have emerged as a critical component in these applications, offering a unique blend of lightweight properties, excellent corrosion resistance, and robust mechanical performance.

Marine aluminum flat bars are flat-shaped aluminum products fabricated specifically from marine-grade aluminum alloys. These bars are extensively utilized in offshore platform construction, serving as structural components, reinforcement elements, connectors, and fabrication aids. The unique challenges in offshore environments, including constant exposure to seawater, strong winds, and variable loads, demand materials that resist corrosion, fatigue, and mechanical wear ― capabilities that marine aluminum simultaneously excels in.

Functions and Applications

1. Structural Framework and Reinforcement

Flat bars form integral parts of the offshore platform’s framework. They provide stiffening, support mounting points for equipment, and contribute to overall rigidity. Due to their flat shape, these bars enable easy integration into truss configurations, shear panels, and bracing arrangements while ensuring uniform load distribution.

2. Corrosion and Weather Resistance

Operating in saline environments necessitates materials with intrinsic corrosion resistance. Marine aluminum alloys offer a naturally forming oxide layer that shields against pitting and crevice corrosion caused by seawater. This resistance ensures longevity and reduces maintenance overhead on offshore facilities, where repair costs can be substantially high.

3. Welding and Fabrication Compatibility

Marine aluminum flat bars provide excellent weldability, allowing them to be seamlessly joined with other structural components. This welding compatibility allows engineers and fabricators to produce intricate assemblies with precision, optimized for the complex geometries of offshore platforms.

4. Lightweight Strength Advantage

Weight reduction is a critical consideration in offshore platform design, impacting foundational loads and installation logistics. Aluminum’s high strength-to-weight ratio directly benefits fabrication and transportation, facilitating quicker deployment while maintaining structural reliability.

Technical Details and Specifications

Alloy Selection & Temper Designations

Marine aluminum flat bars are frequently produced using high-grade 5xxx-series aluminum alloys, typically the 5083 and 5086 variants, owing to their excellent corrosion resistance and mechanical strength.

- 5083 Alloy: Offers ultimate tensile strength up to 345 MPa and superior corrosion resistance in marine atmospheres.

- 5086 Alloy: Known for slightly improved strength and performance in welded structures, with tensile strength about 310 MPa.

Standard temper designations include:

- H111: Non-heat-treated, exhibiting fair ductility and strength; often used when fabrication flexibility is prioritized.

- H112: Non-heat-treated but strain hardened, suitable for moderate strength requirements.

- H116: Heat-treated for enhanced corrosion resistance, especially in welded structures.

- H321: Strain hardened and stabilized solution-annealed, conducive for high-strength requirements in marine service.

These temper conditions allow customization of mechanical and corrosion properties depending on specific load-bearing specifications in offshore designs.

Common Dimensional Parameters

Typical thickness ranges from 3 mm to 50 mm and varying widths between 20 mm to 200 mm, though custom dimensions can be produced as per design needs. Flat bars are supplied with a consistent flat profile, minimizing tolerances instrumental for load simulations in structural design software.

Chemical Composition Parameters

To comply with international standards (e.g., ASTM B209 and BS EN 573-3), marine aluminum flat bars conform to tightly controlled chemical specifications to assure consistent performance on offshore installations.

| Element | 5083 Alloy (%) | 5086 Alloy (%) |

|---|---|---|

| Aluminum (Al) | Balance | Balance |

| Magnesium (Mg) | 4.0 – 4.9 | 4.0 – 4.9 |

| Manganese (Mn) | 0.4 – 1.0 | 0.4 – 1.0 |

| Iron (Fe) | ≤0.4 | ≤0.5 |

| Silicon (Si) | ≤0.4 | ≤0.25 |

| Copper (Cu) | ≤0.1 | ≤0.1 |

| Zinc (Zn) | ≤0.25 | ≤0.25 |

| Chromium (Cr) | 0.05 – 0.25 | 0.05 – 0.25 |

these chemical properties is crucial in selecting a marine aluminum flat bar that does not just resist corrosion but also ensures mechanical properties align with offshore structural integrity criteria.

Compliance with Offshore Fabrication Standards

Offshore platform fabrication involving marine aluminum flat bars typically uses industry standards such as:

- ASTM B928: Standard specification for aluminum alloy rolling flat products for marine environments.

- AAD Table (Aluminium Association Design Tables): Regulatory guidelines for acceptable stress, allowable thickness, and welding procedures.

- NACE MR0175 / ISO 15156: Ensuring material resistance to sulfide stress cracking in corrosive environments commonly found during hydrocarbon production offshore.

Additionally, certifications related to welding compatibility and structural performance tests confirm that marine aluminum flat bars meet stringent quality assurance protocols.

Marine aluminum flat bars uniquely combine strength, corrosion resistance, and lightweight properties, shaping the future of offshore platform fabrication. Their specific alloys, temper conditions, and adherence to exacting chemical and dimensional parameters allow engineers to confidently employ these components under tirelessly harsh marine environments.

Selecting the appropriate alloy, temper, and dimensions aligned with performance standards guarantees efficient fabrication, long-term reliability, and adaptability on offshore projects. As the offshore technology sector advances with ever-stringent engineering demands, marine aluminum flat bars remain an indispensably functional choice, bridging innovative design with durable material performance.

For premium marine aluminum flat bars suitable for your offshore platform fabrication needs, contact our expert team to customize specifications aligned precisely to your engineering requirements.

Related Products

5083 marine aluminum flat bar

5083 aluminum flat bars belong to the 5xxx series of aluminum-magnesium alloys, known primarily for their superior resistance to seawater corrosion and salt spray.

View Details6061 marine aluminum round bar

6061 aluminum belongs to the 6xxx series alloys, alloyed primarily with magnesium and silicon. In the T6 temper, it undergoes solution heat treatment and artificial aging, resulting in enhanced mechanical properties while maintaining excellent corrosion resistance.

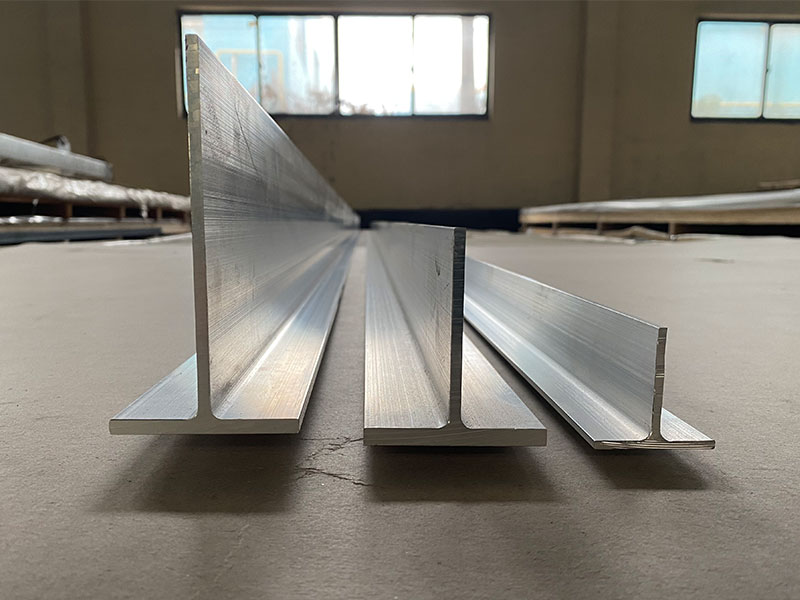

View DetailsMarine aluminum channels

Marine Aluminum Channels are U-shaped aluminum profiles produced from alloys such as 5083, 5052, and 6061, known for their excellent marine corrosion resistance and superior mechanical strength.

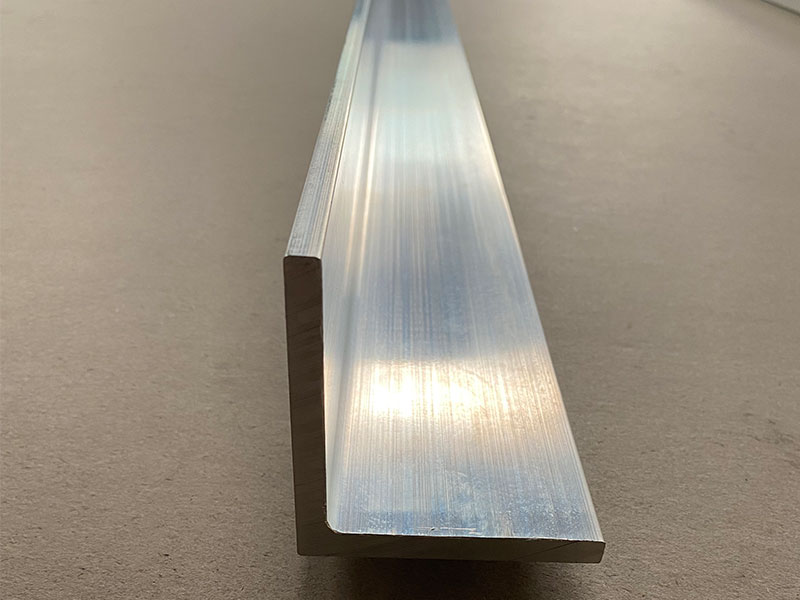

View DetailsMarine aluminum angles

Marine Aluminum Angles are L-shaped cross-sectional aluminum profiles produced from marine-grade aluminum alloys such as 5083, 5052, and 6061.

View Details6061 T6 marine aluminum flat bar

6061 aluminum is classified as a heat-treatable 6xxx series alloy, alloyed primarily with magnesium and silicon. The T6 temper designation indicates that the flat bar has been solution heat-treated and artificially aged to achieve optimum strength and hardness.

View DetailsMarine aluminum Z-shaped sections

Marine Aluminum Z-shaped Sections are fabricated from premium marine-grade aluminum alloys such as 5083, 5052, and 6061. These alloys are well-regarded for their superior corrosion resistance in seawater and marine atmospheres, along with good mechanical strength and excellent weldability.

View DetailsRelated Blog

6061 T6 marine aluminum flat bar

6061 T6 marine aluminum flat bar is a widely used structural and fabrication material within the marine industry. Combining excellent strength, good corrosion resistance, weldability, and formability.

View Details6061 Marine Aluminum Angles for Boat Deck Support and Reinforcement

6061 Marine Aluminum Angles are specially designed aluminum alloy structural components, widely used in marine environments for boat deck support, reinforcement, and framework.

View DetailsMarine Aluminum Flat Bar for Boat Frame Reinforcement and Repair

Superior durability and corrosion resistance of Marine Aluminum Flat Bars, specifically engineered for boat frame reinforcement and repair. Learn about alloy compositions, mechanical properties, tempering conditions, and industry-compliant standards that

View Details6061 Marine Aluminum Channels for High Strength Coastal Engineering

Marine aluminum has revolutionized coastal engineering, and at the fulcrum of this evolution lies 6061 marine aluminum channels. These channels bring unparalleled strength, corrosion resistance.

View DetailsMarine Aluminum Round Bar for Durable Offshore Ship Parts

In the maritime industry, where durability, corrosion resistance, and structural integrity are paramount, choosing the right material for offshore ship parts is critical.

View Details5083 Marine Aluminum Round Bar for High Strength Offshore Reinforcements

In the demanding world of offshore engineering, materials must withstand severe environmental conditions without compromising structural integrity. One such pivotal material is the 5083 Marine Aluminum Round Bar.

View Details

Leave a Message