Marine Aluminum Elbow for Fuel System Installations

When it comes to designing and installing fuel systems in marine environments, using the right materials is paramount. Among these materials, Marine Aluminum Elbows is know due to their remarkable properties and advantages.

What is Marine Aluminum?

Marine Aluminum is a specific category of aluminum alloy engineered to withstand the harsh conditions typical in marine environments. With its lightweight and non-corrosive properties, marine aluminum is ideal for critical installations like fuel systems below deck or in intrusive areas exposed to saltwater and humidity.

Exceptional Advantages of Marine Aluminum Elbow

Corrosion Resistance: Marine aluminum has a natural oxide coating that forms on its surface, providing superior resistance to corrosion, particularly from seawater and other environmental elements.

Lightweight yet Sturdy: Unlike materials like steel, marine aluminum allows for easier handling during installation while affording ample strength for durability.

Versatility in Applications: Thanks to various alloys and temperatures available in the marine aluminum range, elbows can easily accommodate diverse design constraints in fueling systems.

Standard Compliance: Designed with rigorous standards, marine aluminum elbows ensure integrity and reliability when used in pressured systems—all vital for safety in hostile conditions.

Technical Specifications of Marine Aluminum Elbows

To effectively work within any marine setup, the specifics of marine aluminum elbows is crucial. Various parameters affect their performance while contrasting various alloys can provide optimization when implementing a solution specific to your needs.

Parameters

| Parameter | Value |

|---|---|

| Alloy Grades | 5083, 6061, 3003 |

| Tempering | H32, H34 acquire superiority in strength |

| Diameter | Choice between 2" to 10", made for different needs |

| Wall Thickness | Typically ranged from 2mm to 5mm based on impedance effects |

| Thermal Conductivity | Approx. 120-180 W/m²K, superior to many metals |

| Chemical Stability | Non-reactive to hydrocarbons and common fuels |

Alloy Tempering

Alloy tempering code followed is essential for applications like fuel systems that may experience high fluctuations in pressure. Here’s how specific tempering conditions enhance their mechanical properties:

- H32 Tempered Elements: Tough adequate for general strength without compromising flexibility.

- H34 Tempering: Delivers strength strength under a fatigued environment, a common challenge faced in marine fuel systems. Suitable when high stress may culminate such as during fuel transport.

Chemical Properties

Selling points and deployment ease can be maximized by the elemental compositions within Marine Aluminum Elbows. Here’s a concise table of chemical composition affecting marine usage:

| Element | Percentage (%) |

|---|---|

| Aluminum | 90.7 - 94.7 |

| Silicon | 0.7 - 1.3 |

| Magnesium | 4.0 - 4.9 |

| Manganese | 0.4 - 1.0 |

| Zinc | 0.25 - 0.5 |

| Copper | Trace |

| Iron | 0.5 Max |

| Others | Balance to allowable |

Implementation Standards

When installing marine aluminum elbows within fuel systems, guidelines, and regulations must be strictly followed to ensure longevity and safety:

ISO Standards: Adherence to ISO 8020 defines the specifications for parts in marine and logistic services, ensuring compliance through rigorous tolerance checks.

NACE Recommended Practices: Protection against pressures developments without introducing weaknesses associated typically due to corrosion.

HACCP.P( Hazard Analysis Critical Control Point) considerations in deploying fuel systems to assess residual biodegradability of any resultant materials if lead to emergencies.

Related Products

6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

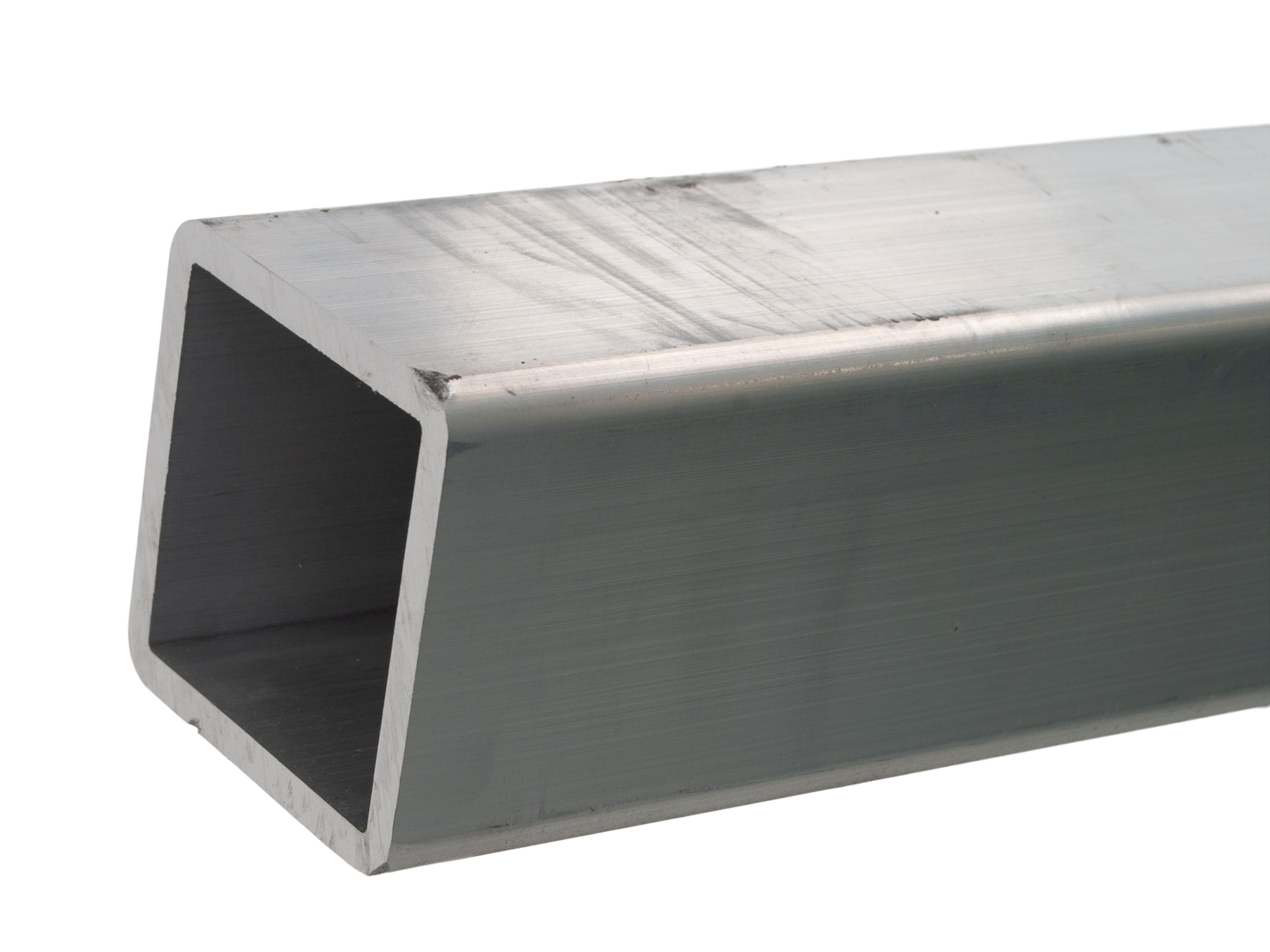

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View DetailsMarine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View DetailsRelated Blog

Custom Marine Aluminum Elbow for Ship to Ship Fuel Transfer

In the intricate and highly demanding marine environment, efficient and reliable fuel transfer is paramount — especially during ship-to-ship (STS) operations. Central to this process is the often unsung hero: the custom marine aluminum elbow.

View DetailsMarine Aluminum Elbow for Fuel System Installations

When it comes to designing and installing fuel systems in marine environments, using the right materials is paramount. Among these materials, Marine Aluminum Elbows is know due to their remarkable properties and advantages.

View Details6061 Marine Aluminum Tubes for Custom Marine Construction

When it comes to building robust, lightweight, and corrosion-resistant structures for marine applications, 6061 Marine Aluminum Tubes unquestionably lead the pack.

View Details6061 Marine Aluminum Tubes for Marine Machinery Support Systems

6061 Marine Aluminum Tubes: Essential for Marine Machinery Support SystemsIn the complex machinery and construction of the marine industry, the materials crafted for durability and management play a pivotal role.

View Details5083 Marine Aluminum Tubes for Boat Building and Fabrication

In the demanding environment of marine vessel construction and fabrication, the selection of high-quality materials is crucial for ensuring durability, safety, and superior performance.

View DetailsHigh Temperature Marine Aluminum Elbow for Power Plant Piping

In the demanding environments of power plant piping systems, particularly those situated in marine locations, the need for corrosion-resistant, heat-tolerant, and mechanically robust pipe fittings is critical.

View Details

Leave a Message