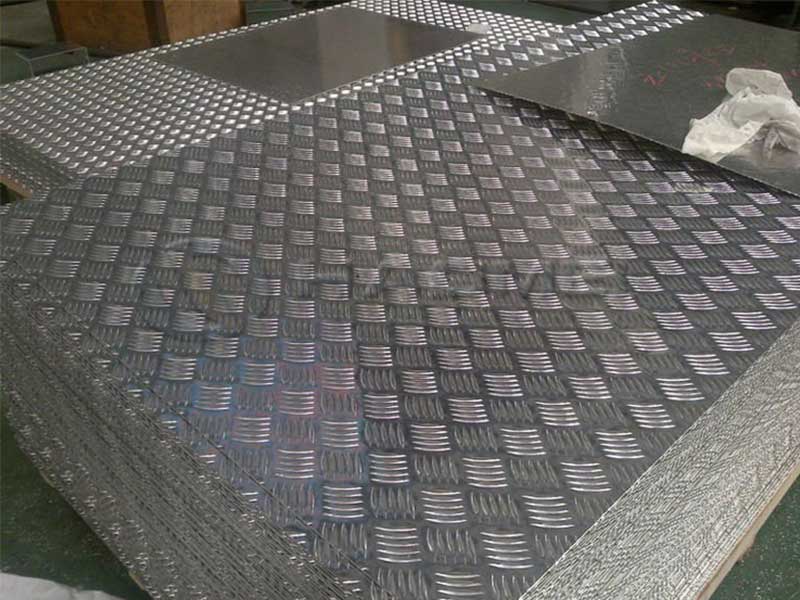

Marine Grade Plate Aluminum Sheet 5083 O H116

When it comes to marine construction and offshore applications, selecting the right material is crucial. Marine Grade Aluminum Plate 5083 O H116 stands out as a top-tier solution, blending excellent mechanical properties, corrosion resistance, and ease of fabrication.

Marine Aluminum Plate 5083

Alloy 5083 is a non-heat-treatable aluminum-magnesium alloy classified under the 5xxx series. Recognized for exceptional corrosion resistance—particularly in seawater—and robust mechanical performance, it's one of the most favored alloys in marine engineering. The “O” temper indicates that the metal is annealed (softened), and coupled with the “H116” designation, it informs us the product met strict control criteria to enhance mechanical properties and corrosion resistance after post-weld heat treatment.

By design, Marine Aluminum 5083 O H116 provides superior yield strength and toughness compared to other aluminum alloys (raising the bar for application in harsh, saltwater environments where longevity and safety are vital).

Functions of 5083 O H116 Marine Aluminum Sheet

- Corrosion Resistance: The alloy contains approximately 4.0-4.9% magnesium, boosted by small amounts of manganese and chromium, forming a protective oxide layer that defends against seawater and marine atmosphere oxidation.

- Enhanced Weldability: Excellent weldability, combined with low susceptibility to stress corrosion cracking in marine environments, makes 5083 O H116 prime for welded structures like ship hulls and offshore platforms.

- High Strength-to-Weight Ratio: The alloy supports lightweight structural elements without compromising durability and load-bearing demands—crucial for fuel efficiency and ease of handling.

- Good Formability: The annealed (O) condition tempered to H116 ensures flexibility required to shape complex boat and ship frames.

- Post-Weld Mechanical Properties: The H116 temper maintains mechanical strength consistent with design parameters even after welding and subsequent environmental exposure.

Common Applications in Marine Environments

Marine aluminum 5083 O H116 is engineered for products rigorously tested and certified to endure hostile maritime conditions. Common applications include:

- Shipbuilding: Hulls, bulkheads, and superstructures used in both recreational and commercial vessels.

- Offshore Platforms: Structural components and cladding where chemical stability in salt-laden air is necessary.

- Boat Decking & Railings: Lightweight and durable parts subjected to constant moisture, salt, and mechanical wear.

- Manufacturing of Marine Tanks: Fuel or ballast tanks benefiting from corrosion and leakage resistance.

- Cryogenic and Refrigerated Containers: Due to excellent mechanical properties at lowered temperatures.

These selective uses are dictated by the alloy’s capability to meet marine industry codes and standards.

Technical Specifications and Implementation Standards

industry parameters and quality requirements helps implement 5083 O H116 accurately.

| Parameter | Specification |

|---|---|

| Alloy system | Al-Mg (Aluminum-Magnesium) |

| Composition (% by weight) | Mg: 4.0–4.9; Mn: 0.4–1.0; Cr: 0.05–0.25; Fe ≤ 0.4; Si ≤ 0.4; Remaining Al |

| Temper | O (Annealed), complied with H116 enhanced welding specification |

| Density | Approx. 2.66 g/cm³ |

| Yield strength (Rp 0.2) | ~260 MPa (depending on thickness) |

| Tensile strength | 290-350 MPa |

| Elongation | ≥12% (depending on thickness and temper) |

| Modulus of Elasticity | 70 GPa |

| Corrosion resistance | Highly resistant to pitting and intergranular corrosion in seawater |

| Thermal conductivity | Around 108 W/(m·K) |

Standards to Note:

- ISO 6361 — Specification for “Wrought Aluminium and Aluminium Alloy Sheets, Strips and Plates.”

- ASTM B209 — Aluminum and Aluminum-Alloy Sheet and Plate.

- ABS (American Bureau of Shipping) & DNV (Det Norske Veritas) certifications specifically outline performance under marine conditions.

- AA (Aluminum Association) Designation — 5083 H116 temper.

H116 temper filtration implies post-welding mechanical strength and corrosion criteria have been tested per relevant codes, especially for application in marine structures entrusted with safety.

Chemical Properties Breakdown

| Element | Content (%) |

|---|---|

| Aluminum (Al) | Balance (~90.0+) |

| Magnesium (Mg) | 4.0 – 4.9 |

| Manganese (Mn) | 0.4 – 1.0 |

| Chromium (Cr) | 0.05 – 0.25 |

| Iron (Fe) | ≤ 0.4 |

| Silicon (Si) | ≤ 0.4 |

| Copper (Cu) | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.25 |

The synergy of magnesium and manganese greatly improves corrosion resistance whereas chromium expands resistance in very aggressive marine atmospheres. Trace impurities are minimized to maintain structural coherence.

Marine Grade 5083 O H116 helper outperforms many metals by delivering the crucial trifecta of toughness, lightweight strength, and outstanding chloride resistance. From initial fabrication to long-term installation, the technical strengths of Marine Aluminum Plate 5083 make it the ultimate choice for reliable and efficient marine and offshore systems.

Investing in 5083 O H116 means engineering longevity, reduced maintenance, and compliance with the rigorous demands of marine industry regulators—ensuring marine operations sail smoothly for years to come.

Whether building a luxury yacht or configuring a critical offshore platform, Marine Aluminum Alloy 5083 in O H116 temper stays steadfast to keep performance and safety afloat. For technical supply and expert advice, choosing a reliable provider specializing in marine-grade plates fuels project success with confidence.

Author: Marine Aluminum Specialist | Leading supplier of premium marine aluminum solutions

Tags: Marine Aluminum, Aluminum 5083, H116 Temper, Marine Sheets, Corrosion Resistance, Shipbuilding Materials

Related Products

Marine 5383 aluminum plate

The 5383 aluminum alloy belongs to the 5xxx series of aluminum-magnesium alloys known for remarkable resistance to marine corrosion and high strength.

View DetailsMarine aluminum steel clad plate

Aluminum / Steel Clad Plates consist of a sandwich construction in which a layer of marine-grade aluminum alloy is metallurgically bonded to a steel substrate.

View DetailsMarine 5052 aluminum plate

Marine 5052 Aluminum Plate is noted for its exceptional resistance to corrosion caused by seawater, salt spray, and marine atmospheres.

View DetailsMarine 5083 aluminum plate

Marine 5083 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys and is classified as a non-heat-treatable alloy. Its high magnesium content (typically 4.0–4.9%) enhances its corrosion resistance, especially against seawater-related degradation such as pitting and stress corrosion cracking.

View DetailsMarine heavy duty aluminum plate

Marine Heavy Duty Aluminum Plates Sheets generally refer to thick aluminum alloy plates and heavy gauge sheets produced from marine-grade alloys such as 5083, 5086, 5059, and 5383.

View DetailsMarine 5059 aluminum plate

Marine 5059 Aluminum Plate is distinguished by its high magnesium content and carefully balanced alloying elements, designed to maximize strength without compromising corrosion resistance.

View DetailsRelated Blog

5083 marine grade aluminium plate for ship building

5083 Marine Grade Aluminium Plate: The Backbone of Modern ShipbuildingWhen it comes to building durable, efficient, and lightweight vessels, 5083 marine grade aluminium plate stands out as a premier material choice.

View DetailsAluminum Sheet Plate alloy 5083 H111 for boat application

When it comes to manufacturing high-performance boats that demand strength, corrosion resistance, and long-lasting durability, Aluminum Sheet Plate Alloy 5083 H111 stands out as a superior material.

View DetailsMarine Aluminum Alloy Plate 5052 5083 6061

Marine environments pose extreme challenges—constant exposure to saltwater corrosion, mechanical stresses, and environmental fluctuations demand materials that combine strength, durability, and corrosion resistance.

View Details5083 5754 5182 aluminum alloy plate for boat

When it comes to constructing durable, lightweight, and corrosion-resistant boats, marine-grade aluminum alloy plates like 5083, 5754, and 5182 is know as the industry champions.

View Details5083 H111 H112 Aluminium Alloy plate untuk Boat

Temukan keunggulan pelat aluminium 5083 H111 dan H112 untuk aplikasi kapal. Pelajari spesifikasi teknis, sifat kimia, tempering, standar implementasi, serta alasan utama pemilihannya di industri laut.

View Details7.5 mm marine grade 5083 h16 h22 aluminium sheet plate

Marine environments are notoriously harsh, subjecting materials to saltwater corrosion, mechanical stress, and temperature fluctuations. Among the materials engineered to withstand these conditions, 7.

View Details

Leave a Message