High Temperature Marine Aluminum Elbow for Power Plant Piping

In the demanding environments of power plant piping systems, particularly those situated in marine locations, the need for corrosion-resistant, heat-tolerant, and mechanically robust pipe fittings is critical. The High Temperature Marine Aluminum Elbow is a specialized aluminum alloy fitting designed to meet these challenges. Manufactured with precision and utilizing advanced aluminum alloys, this elbow plays an essential role in ensuring long-term system integrity under harsh operating conditions.

Features

1. Alloy Composition and Strength

Our marine aluminum elbow is typically fabricated from high-performance alloys such as 6061-T6 or 5083-H321, chosen specifically for their excellent strength-to-weight ratio and corrosion resistance especially in saltwater or marine atmospheres.

| Alloy | Ultimate Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Corrosion Resistance | Weldability |

|---|---|---|---|---|---|

| 6061-T6 | 310 – 350 | 275 – 310 | 10 – 12 | High (good) | Excellent |

| 5083-H321 | 295 – 320 | 215 – 270 | 10 – 17 | Excellent | Good |

2. High Temperature Performance

Marine aluminum elbows are often subjected to temperatures up to 250°C depending on pipe content which might include hot condensate, steam, or cooling fluids. The selected aluminum alloy maintains mechanical properties and dimensional stability up to these high temperatures, ensuring safe directional changes in piping without failure or leakage.

3. Corrosion Resistance

The elbow exhibits outstanding resistance to marine salt spray, chlorides, and thermal degradation. This long-lasting corrosion resistance distinctively lowers maintenance needs and extends pipeline lifespan compared to steel or unsupported aluminum alternatives.

4. Dimensional Accuracy and Surface Finish

Manufactured to precise industry standards such as ASTM B241 and ASME B16.9, these elbows come in standard bend radii (typically 1D, 1.5D, or 3D) and sizes ranging from 1 inch to 24 inches diameter (custom sizes also available). The smooth surface minimizes flow turbulence and reduces the possibility for cavitation or premature wear.

| Parameters | Details |

|---|---|

| Bend Angle | 45°, 90°, 180° common |

| Radius | 1D (standard), 1.5D (medium), 3D (long radius) |

| Diameter Range | 25 mm (1") to 600 mm (24") |

| Wall Thickness | Schedule 10 to Schedule 80 or custom |

| Surface Finish | Mill Finish, anodized or coated |

5. Weight and Handling

With aluminum’s significantly lower density (~2.7 g/cm³) compared to steel (~7.85 g/cm³), handling and installation become much simpler, reducing labor time and equipment costs in tight maritime or onsite power generation plant piping arrangements.

Applications

Power Plant Piping Systems

- Steam and Condensate Lines: Suitable for directing high-temperature steam or condensate while withstanding thermal shock.

- Cooling Water Piping: Ideal for saltwater intake/outtake piping where corrosion resistance is critical.

- Fuel Gas and Air Piping: Heat stable performance in piping systems transporting heated gases.

- Waste Heat Recovery Systems: Long-term durability in exhaust and flue gas lines subjected to hot, corrosive environments.

Marine Environments

- Offshore platforms, shipyards, and coastal power plants benefit from the corrosion resistance and lightweight features.

- Perfect for saltwater-cooled heat exchangers and pumps' piping.

General Industrial Applications

- Any facility that requires lightweight, corrosion-resistant, and thermally stable elbow fittings for piping under aggressive marine or industrial conditions.

| Attribute | Specification Range |

|---|---|

| Materials | Aluminum 6061-T6, 5083-H321 |

| Operating Temperature Range | -196°C to +250°C |

| Elbow Angles | 45°, 90°, 180° standard |

| Bend Radius | 1D, 1.5D, 3D |

| Sizes | 1” to 24” diameter |

| Wall Thickness | SDR Schedule 10 to 80 plus custom options |

| Density | 2.7 g/cm³ |

| Corrosion resistance | Excellent against saltwater, marine exposure |

Related Products

Marine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

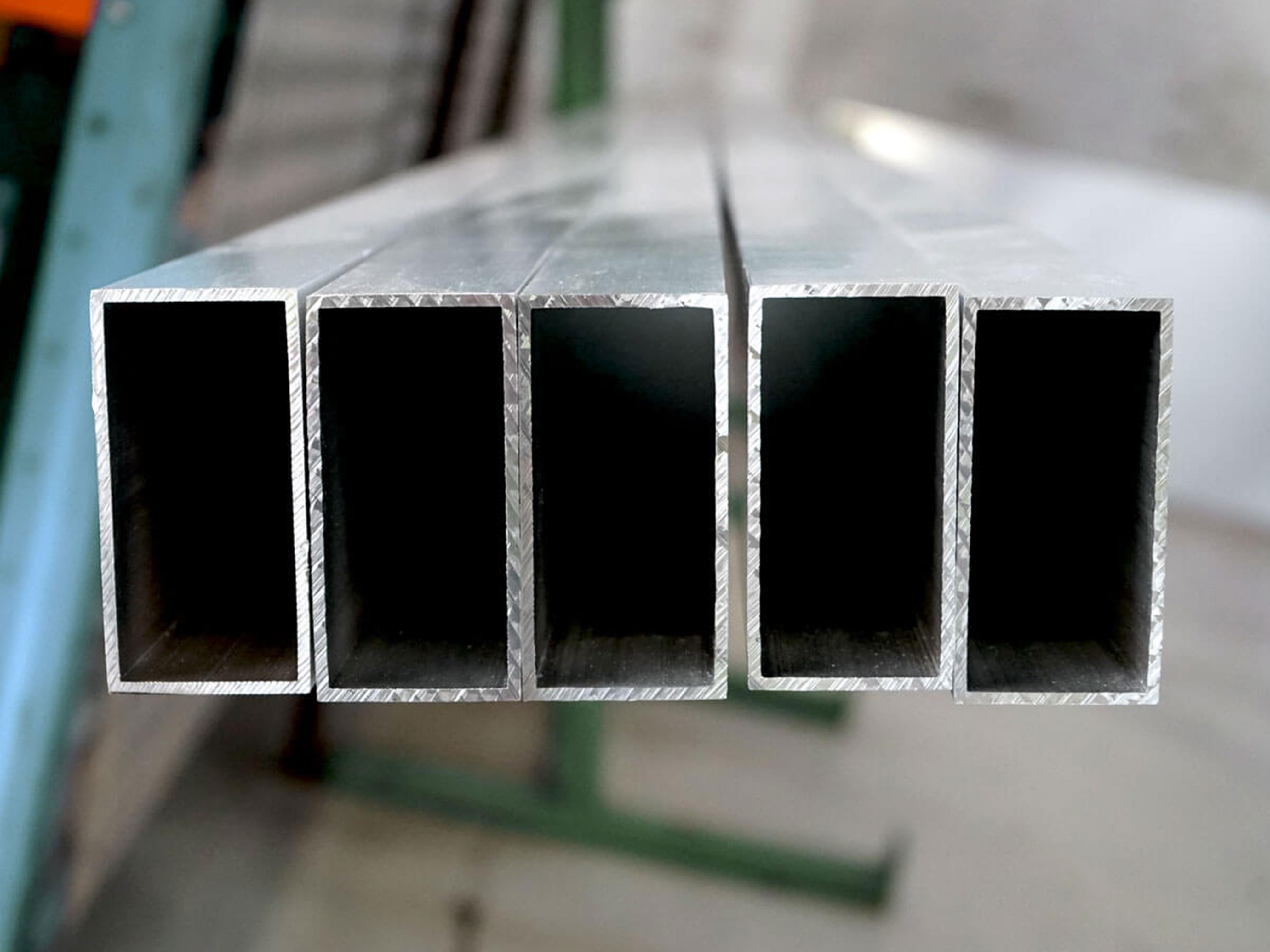

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View DetailsRelated Blog

5083 Marine Aluminum Tubes for Ship Hull Reinforcement Materials

When it comes to building and reinforcing ship hulls, selecting the right material is critical for durability, strength, and resistance to the harsh marine environment.

View DetailsMarine Aluminum Elbow for Offshore Oil Spill Containment Systems

Marine Aluminum Elbow for Offshore Oil Spill Containment Systems: Functions, Applications, and Technical InsightsIn the demanding and often harsh environment of offshore oil spill containment systems, every component requires superior performance.

View Details6082 Marine Aluminum Tubes for Marine Engine Component Support

The 6082 marine aluminum tubes are a premium-grade aluminum alloy offering a balanced blend of strength, corrosion resistance, and excellent machinability.

View DetailsAluminum Elbow for Gas and Liquid Transfer on Marine Vessels

Marine vessels operate amidst some of the most challenging environments, where efficiency, durability, and safety of components in fluid transfer systems are paramount.

View Details6061 Marine Aluminum Tubes for Marine Engineering Projects

Marine engineering demands materials that combine exceptional strength, corrosion resistance, and versatility for reliable performance in harsh seawater environments.

View DetailsMarine Aluminum Pipe Elbow for Desalination Plant Connections

In modern desalination plants, the choice of piping components is critical to ensuring efficiency, longevity, and resistance to harsh marine environments.

View Details

Leave a Message