11 mm thick marine aluminium plate 5083

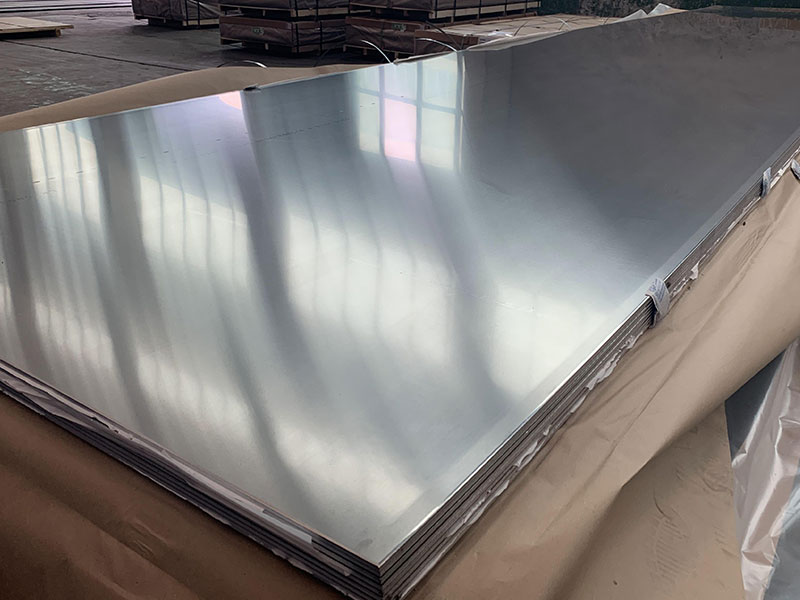

Marine industries demand materials that offer exceptional strength, corrosion resistance, and durability under harsh environmental conditions. The 11 mm thick marine aluminium plate 5083 is specifically designed to meet these rigorous standards. This aluminum alloy plate is widely recognized for its excellent mechanical properties and superior anti-corrosion capabilities, making it an ideal choice for diverse marine applications.

Aluminium alloy 5083 is part of the 5000 series aluminum-magnesium alloys, known for outstanding corrosion resistance in seawater and excellent weldability. The 11 mm thickness provides an optimal balance between lightweight performance and robust structural integrity, crucial for marine vessels and offshore structures.

Features of 11 mm 5083 Marine Aluminium Plate

| Feature | Description |

|---|---|

| Corrosion Resistance | Exceptional resistance to seawater and industrial chemicals due to high magnesium content |

| Mechanical Strength | High tensile strength combined with excellent toughness and fatigue resistance |

| Weldability | Excellent weldability without compromising corrosion resistance or mechanical integrity |

| Formability | Good formability suitable for bending and shaping complex profiles without compromising strength |

| Lightweight | Lower weight compared to steel, improving fuel efficiency and payload capacity |

| Thickness | Precisely manufactured at 11 mm thickness for structural applications |

Chemical Composition of Aluminium Alloy 5083

The following table outlines the nominal chemical composition of Aluminium 5083 which directly influences its remarkable properties.

| Element | Percentage Range (%) |

|---|---|

| Magnesium (Mg) | 4.0 - 4.9 |

| Manganese (Mn) | 0.4 - 1.0 |

| Chromium (Cr) | 0.05 - 0.25 |

| Iron (Fe) | ≤ 0.4 |

| Silicon (Si) | ≤ 0.4 |

| Copper (Cu) | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 |

| Aluminium (Al) | Balance |

Technical Specifications

| Property | Value | Test Standard |

|---|---|---|

| Thickness | 11 mm | ASTM B209, ISO 6361 |

| Tensile Strength | 275 - 310 MPa | ASTM E8 |

| Yield Strength (0.2% offset) | ≥ 145 MPa | ASTM E8 |

| Elongation (50 mm) | ≥ 12 % | ASTM E8 |

| Hardness (HB) | ~60 | ASTM E10 |

| Density | 2.66 g/cm³ | ASTM B297 |

| Thermal Conductivity | 121 W/m-K at 25°C | |

| Melting Range | 590 - 650°C |

Benefits of Using 11 mm 5083 Marine Aluminium Plate

- Resistance to Marine Environments: Ideal for hulls, decks, and superstructures exposed to salty seawater — minimizes maintenance and extends lifespan.

- Lightweight and Stress Handling: Ensures enhanced speed and fuel efficiency in vessels without compromising structural strength.

- Weld and Fabrication Friendly: Easily welded through various processes (TIG, MIG, etc.) supporting modular construction methods.

- Durability against Fatigue Loading: Suitable for continuously stressed applications which experience dynamic wave and wind loads.

- Minimal Corrosion Fatigue: Stands up to the challenges of long-term service life in harsh chemical marine atmospheres while maintaining strength.

Typical Applications

| Application Area | Description |

|---|---|

| Shipbuilding | Hull plating, decks, superstructure components, bulkheads |

| Marine Transportation | Ferries, yachts, tankers, container ships where lightweight and corrosion resistance are essential |

| Offshore Platforms | Structural components, support frames, and walkways exposed to saltwater environment |

| Transport Containers | Refrigerated containers and containers used in salty maritime environments |

| Pressure Vessels and Tanks | Storage for seawater and chemicals in marine and offshore installations |

| Automotive & Aerospace | Enhancing lightweight components where high strength and corrosion resistance matter |

Related Products

Marine 5083 aluminum plate

Marine 5083 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys and is classified as a non-heat-treatable alloy. Its high magnesium content (typically 4.0–4.9%) enhances its corrosion resistance, especially against seawater-related degradation such as pitting and stress corrosion cracking.

View DetailsMarine 5052 aluminum plate

Marine 5052 Aluminum Plate is noted for its exceptional resistance to corrosion caused by seawater, salt spray, and marine atmospheres.

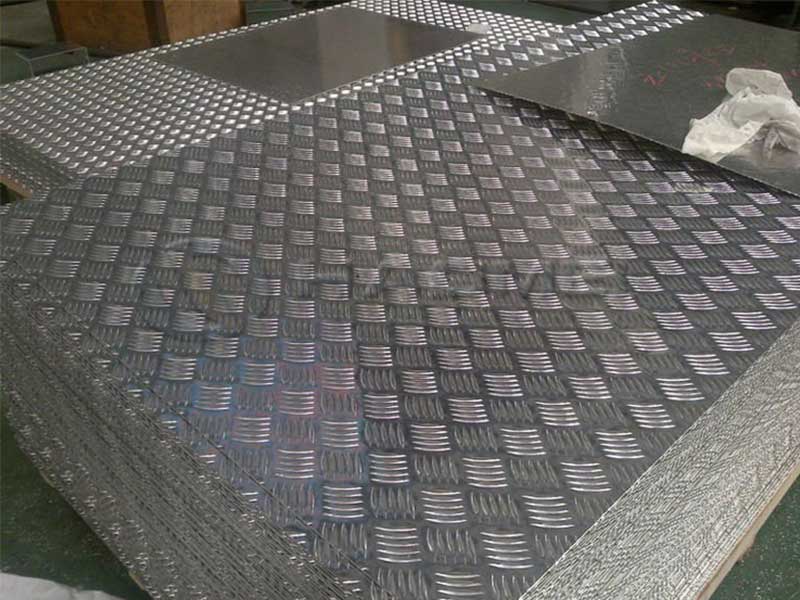

View DetailsMarine heavy duty aluminum plate

Marine Heavy Duty Aluminum Plates Sheets generally refer to thick aluminum alloy plates and heavy gauge sheets produced from marine-grade alloys such as 5083, 5086, 5059, and 5383.

View DetailsMarine 5059 aluminum plate

Marine 5059 Aluminum Plate is distinguished by its high magnesium content and carefully balanced alloying elements, designed to maximize strength without compromising corrosion resistance.

View DetailsMarine 5383 aluminum plate

The 5383 aluminum alloy belongs to the 5xxx series of aluminum-magnesium alloys known for remarkable resistance to marine corrosion and high strength.

View DetailsMarine aluminum steel clad plate

Aluminum / Steel Clad Plates consist of a sandwich construction in which a layer of marine-grade aluminum alloy is metallurgically bonded to a steel substrate.

View DetailsRelated Blog

5083 H111 H112 Aluminium Alloy plate untuk Boat

Temukan keunggulan pelat aluminium 5083 H111 dan H112 untuk aplikasi kapal. Pelajari spesifikasi teknis, sifat kimia, tempering, standar implementasi, serta alasan utama pemilihannya di industri laut.

View Details5083 5754 5182 aluminum alloy plate for boat

When it comes to constructing durable, lightweight, and corrosion-resistant boats, marine-grade aluminum alloy plates like 5083, 5754, and 5182 is know as the industry champions.

View Details7.5 mm marine grade 5083 h16 h22 aluminium sheet plate

Marine environments are notoriously harsh, subjecting materials to saltwater corrosion, mechanical stress, and temperature fluctuations. Among the materials engineered to withstand these conditions, 7.

View DetailsAluminum Sheet Plate alloy 5083 H111 for boat application

When it comes to manufacturing high-performance boats that demand strength, corrosion resistance, and long-lasting durability, Aluminum Sheet Plate Alloy 5083 H111 stands out as a superior material.

View Details5083 0.5mm aluminum plate sheet for marine

5083 0.5mm aluminum plate sheet is a thin, high-strength marine-grade alloy offering excellent corrosion resistance, good weldability, and superior formability. Ideal for shipbuilding, boat decking, marine fittings, and coastal structures.

View Details5083 H116 marine grade aluminum alloy sheet plate

Superior corrosion resistance and high strength of 5083 H116 marine grade aluminum alloy sheet plate. Ideal for shipbuilding and marine structures, this alloy ensures durability in harsh sea conditions with excellent weldability and excellent workability.

View Details

Leave a Message