7.5 mm marine grade 5083 h16 h22 aluminium sheet plate

Marine environments are notoriously harsh, subjecting materials to saltwater corrosion, mechanical stress, and temperature fluctuations. Among the materials engineered to withstand these conditions, 7.5 mm marine grade 5083 aluminium sheet plates with tempers H16 and H22 is know as a benchmark of durability and versatility. the nuanced engineering behind this alloy and its tempering methods offers invaluable insight into why it reigns supreme in marine applications.

What is 7.5 mm Marine Grade 5083 Aluminium Sheet Plate?

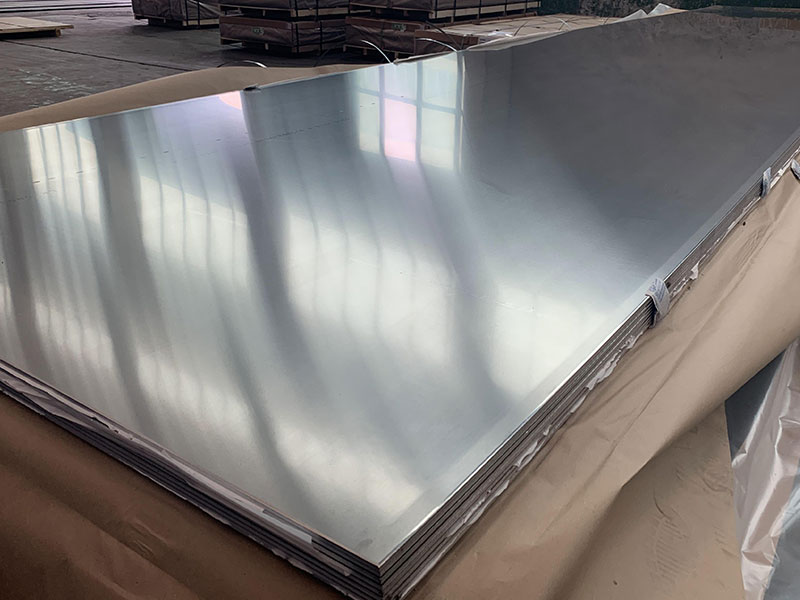

Marine grade 5083 aluminium is an alloy predominantly composed of aluminium, magnesium, and trace elements, specially formulated to provide exceptional corrosion resistance, especially against seawater. The 7.5 mm thickness elevates its mechanical robustness, making it suitable for structural applications.

7.5mm thick 5083 H16/H22 marine grade aluminum sheet plate is a workhorse in our factory. We see it predominantly used in applications requiring high strength, excellent corrosion resistance, and weldability. The H16 temper offers a good balance between strength and formability, making it ideal for moderately complex parts like hull sections or bulkheads. However, the slightly softer nature sometimes necessitates additional bracing during fabrication to prevent warping during welding. We've found that pre-heating prior to welding, especially with thicker sections like this, is crucial for achieving sound welds and minimizing distortion. Careful control of the welding parameters is vital to avoid cracking, a common issue with higher strength aluminum alloys. The H22 temper, on the other hand, is stronger but less formable, often reserved for components requiring maximum strength, such as heavily loaded structural members.

Our experience highlights the importance of careful material selection based on the specific application. While the higher yield strength of H22 is tempting, it's not always the best choice if the part requires extensive forming. We've had instances where using H22 resulted in cracking during bending operations, leading to scrap and delays. Furthermore, the consistent quality of the supplied sheets is paramount. Inconsistencies in thickness or surface finish can lead to problems during fabrication, resulting in time-consuming rework or even rejection of finished parts. Regular quality checks and close

The designation H16 and H22 indicate work hardening tempers, i.e., the aluminium sheet plate has gone through mechanical processing to increase its strength beyond the annealed state (O temper):

- H16: Strain-hardened and partially annealed to a ¼ hard temper

- H22: Strain-hardened to a 1/8 hard temper

As a result, these tempers optimize tensile strength while preserving excellent ductility, calibrated for balancing toughness and flexibility vital in marine structures.

Technical Parameters & Properties

| Parameter | Specification |

|---|---|

| Alloy Type | 5083 Aluminium |

| Thickness | 7.5 mm |

| Temper | H16 / H22 |

| Density | 2.66 g/cm³ |

| Melting Point | 590 – 650 °C |

| Yield Strength | H16: ~215 MPa; H22: ~220 MPa |

| Ultimate Tensile Strength | H16: ~285 MPa; H22: ~295 MPa |

| Elongation at Break | H16: 12% approx; H22: 10% approx |

Chemical Composition

| Element | Percentage (%) |

|---|---|

| Magnesium (Mg) | 4.0 – 4.9 |

| Manganese (Mn) | 0.4 – 1.0 |

| Chromium (Cr) | 0.05 – 0.25 |

| Iron (Fe) | ≤ 0.4 |

| Silicon (Si) | ≤ 0.4 |

| Copper (Cu) | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.25 |

| Aluminium (Al) | Remainder |

Why Choose 5083 Aluminium Alloy for Marine Use?

1. Superior Corrosion Resistance

Aluminium 5083 owes much of its steadfastness to a high magnesium content, which enhances resistance against pitting and crevice corrosion in seawater and marine atmospheres — a critical benefit in minimizing maintenance costs and extending operational lifetimes for vessels and offshore equipment.

2. Mechanical Stability via H16 and H22 Tempers

While annealed aluminium (O temper) is more malleable, H16 and H22 provide higher yield and tensile strengths. For example, H16 offers a durable toughness with 215 MPa yield strength ideal for the curved sections of hulls and superstructures, whereas H22 tempers provide a marginal increase in strength, preferred in load-bearing or reinforced structural elements.

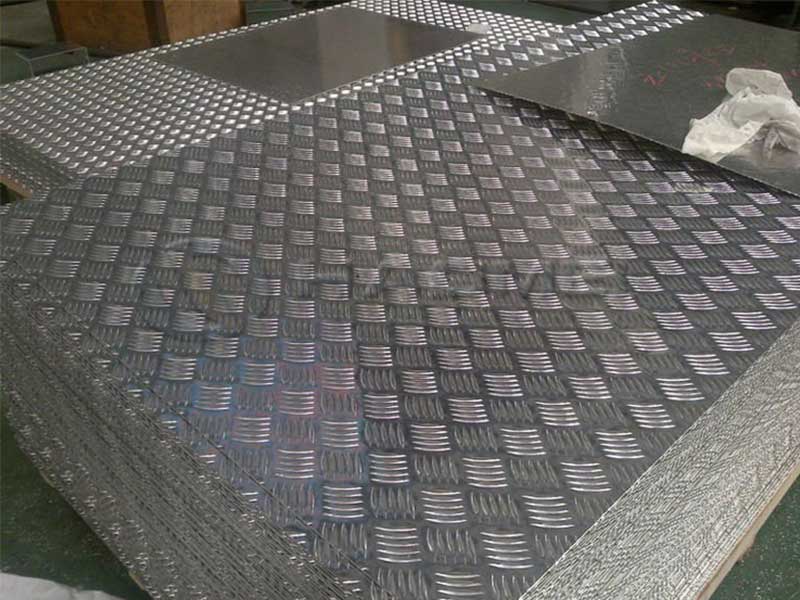

Applications of 7.5 mm 5083 Marine Aluminium Sheet

Shipbuilding and Boat Manufacturing

These alloy sheets fit naturally as the cornerstone for building:

- Hulls of boats and ferries, requiring corrosion resistance coupled with durable structural integrity

- Deck plating and bulkheads, where strength against impact and wear is critical

- Superstructures and bulk containers exposed to atmospheric challenges for years

Offshore Platforms and Maritime Infrastructure

Platforms and floating structures stand to benefit from this alloy's adaptability amidst oceanic chemical exposures and mechanical loads. Its applications include:

- Deck platforms and tanks

- Marine containers and storage facilities

- Components subjected to cyclic stresses and salt spray

Specialized Containers and Cryogenics

Due to 5083 aluminium’s retention of strength at low temperatures, this sheet plate thickness is favored for manufacture of cryogenic containers and pressure vessels utilized offshore or onboard.

Implementation Standards

The production and quality assurance of marine grade 5083 alloy conform predominantly to the following standards:

- ASTM B209 — Standard Specification for Aluminium and Aluminium-Alloy Sheet and Plate

- AA (Aluminium Association) 5083 Specification

- ISO 6361 for general aluminium sheet properties

Furthermore, processes comply with marine classification societies such as ABS, Lloyd’s Register, and DNV GL’s strict guidelines on structural testing, corrosion evaluation, and thickness tolerances ensuring application reliability.

Final Thoughts: Investment in Longevity and Safety

Adopting the 7.5 mm marine grade 5083 aluminium sheet plate with H16 or H22 temper empowers marine engineers and shipbuilders with a material profile that transcends ordinary aluminium. Its cane-scale corrosion resistance combined with tailored mechanical strength underpins safety and durability in the sea’s most challenging environments.

When marine applications demand a dependable balance between strength, corrosion resistance, and fabrication ease, 5083 aluminium, especially in the 7.5 mm thickness and work-hardened tempers like H16 & H22, remains unrivaled as a material solution designed to endure the sea — and time itself.

For those ready to essentialize reliability in their marine constructions, 7.5 mm marine grade 5083 H16 H22 aluminium sheet plates deliver scientific precision in alloying paired with engineering-forward adaptability — making them a trusted, down-to-earth answer to real-world maritime challenges.

Related Products

Marine 5083 aluminum plate

Marine 5083 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys and is classified as a non-heat-treatable alloy. Its high magnesium content (typically 4.0–4.9%) enhances its corrosion resistance, especially against seawater-related degradation such as pitting and stress corrosion cracking.

View DetailsMarine 5086 aluminum plate

5086 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys. Its hallmark is a high magnesium content—generally between 4.0% and 4.9%—which delivers enhanced corrosion resistance, particularly against saltwater and marine atmospheric conditions.

View DetailsMarine aluminum steel clad plate

Aluminum / Steel Clad Plates consist of a sandwich construction in which a layer of marine-grade aluminum alloy is metallurgically bonded to a steel substrate.

View DetailsMarine 5052 aluminum plate

Marine 5052 Aluminum Plate is noted for its exceptional resistance to corrosion caused by seawater, salt spray, and marine atmospheres.

View DetailsMarine heavy duty aluminum plate

Marine Heavy Duty Aluminum Plates Sheets generally refer to thick aluminum alloy plates and heavy gauge sheets produced from marine-grade alloys such as 5083, 5086, 5059, and 5383.

View DetailsMarine 5383 aluminum plate

The 5383 aluminum alloy belongs to the 5xxx series of aluminum-magnesium alloys known for remarkable resistance to marine corrosion and high strength.

View DetailsRelated Blog

Aluminum Alloy Plate 5083 H24 for Marine

OverviewAluminum Alloy Plate 5083 H24 is a high-performance material widely favored in marine engineering due to its excellent combination of high strength, exceptional corrosion resistance, and good weldability.

View Details5083 H116 marine grade aluminum alloy sheet plate

Superior corrosion resistance and high strength of 5083 H116 marine grade aluminum alloy sheet plate. Ideal for shipbuilding and marine structures, this alloy ensures durability in harsh sea conditions with excellent weldability and excellent workability.

View DetailsHot Rol 5052 5083 Aluminum Plate Sheet for Boat

When it comes to marine aluminum, hot rolled 5052 and 5083 aluminum plate sheets hold a distinguished place, primarily due to their impeccable blend of strength, corrosion resistance, and formability — factors crucial for boat manufacturing.

View Details5083 marine grade aluminium plate for ship building

5083 Marine Grade Aluminium Plate: The Backbone of Modern ShipbuildingWhen it comes to building durable, efficient, and lightweight vessels, 5083 marine grade aluminium plate stands out as a premier material choice.

View Details5083 H111 H112 Aluminium Alloy plate untuk Boat

Temukan keunggulan pelat aluminium 5083 H111 dan H112 untuk aplikasi kapal. Pelajari spesifikasi teknis, sifat kimia, tempering, standar implementasi, serta alasan utama pemilihannya di industri laut.

View DetailsMarine Grade 5083, 5082 Aluminum Alloy Sheet Plate

When it comes to materials that perform exceptionally under the harsh conditions of marine environments, Marine Grade aluminum alloys like 5083 and 5082 hold a revered place in the industry’s toolkit.

View Details

Leave a Message