5052 Marine Aluminum Tubes for High Performance Boat Structures

When it comes to high-performance boat structures, the strength, weight, and durability of materials matter enormously. One of the most favored materials in the marine industry is **5052 Marine Aluminum Tubes.

Why Choose 5052 Aluminum?

The 5052 aluminum alloy stands out in marine applications due to its remarkable combination of strength, excellent corrosion resistance, and formability. It caters to specific requirements of high-performance boats, including weight-efficient constructions that sustain heavy service life on water.

Features of 5052 Marine Aluminum

- Corrosion Resistance: 5052 marine-grade aluminum possesses optimal corrosion resistance, protecting boats from harsh marine environments, saltwater exposure, and oxidation.

- Lightweight: Aluminum’s low density offers high-strength-to-weight ratios, enhancing boat speed and efficiency.

- Malleability: Ability to be cold-worked or formed into complex workers makes this aluminum ideal for tube shapes in variable compositions.

- Weldability: It showcases good weldability, a crucial characteristic for constructing boat hulls and frames.

Applications

The 5052 Marine Aluminum tubes are widely used in various marine configurations. Some definitive use cases include:

- Boat Frames and Hulls: Allowing for lightweight structural supports.

- Towers and Masts: Designing masts and integrated components in sailboats.

- Handrails and Guards: Manufactured safely for effective security alongside retaining buoyancy.

- Fuel Tanks: Integral for constructing efficient, hybrid fuel systems.

Technical Specifications

To facilitate a deeper technical , below are tables outlining the chemical composition, physical properties, and mechanical properties of 5052 Marine Aluminum.

Chemical Composition Table:

| Element | Composition (%) |

|---|---|

| Aluminum (Al) | 95.7 - 97.7 |

| Magnesium (Mg) | 2.2 - 2.8 |

| Chromium (Cr) | 0.15 - 0.40 |

| Copper (Cu) | 0.1 |

| Manganese (Mn) | 0.10 |

| Silicon (Si) | 0.25 |

| Zinc (Zn) | 0.10 |

| Iron (Fe) | 0.40 |

Physical Properties Table:

| Property | Value |

|---|---|

| Density | 2.68 g/cm³ |

| Melting Point | 605-650 °C |

| Thermal Conductivity | 138 W/m·K (approx.) |

| Electrical Conductivity | 55% IACS (Conductivity) |

Mechanical Properties Table:

| Property | Value | Test Method |

|---|---|---|

| Ultimate Tensile Strength | 310 MPa (45,000 psi) | ASTM B557 |

| Yield Strength | 228 MPa (33,000 psi) | ASTM B557 |

| Elongation | 12% | ASTM E10 |

| Hardness (HB) | 75 | ASTM E18 |

Alloy Tempering Conditions

5152 is classified with several tempering conditions enhancing its physical properties. Here’s and elaboration on temper states for quality assurance in manufacture:

| Temper Designation | Tempered Condition Description |

|---|---|

| H32 | Strain-hardened & Stabilized to balance maintaining strength and formability. |

| H34 | Similar processes with optimized yield suitable for high-stress applications. |

Implementation Standards

The manufacturing and usage of 5052 MLA comply with various marine and industrial standards such as:

- ASTM B211: Specification for Aluminum and Aluminum-Alloy Hot-Rolled or Cold-Rolled Plates, Sheets, and Strips for REM.

- ABS: American Bureau of Shipping classifications verifying departmental compliance for marine applications.

- ISO 13918: Relevant quality and intrinsic standards.

Related Products

Custom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

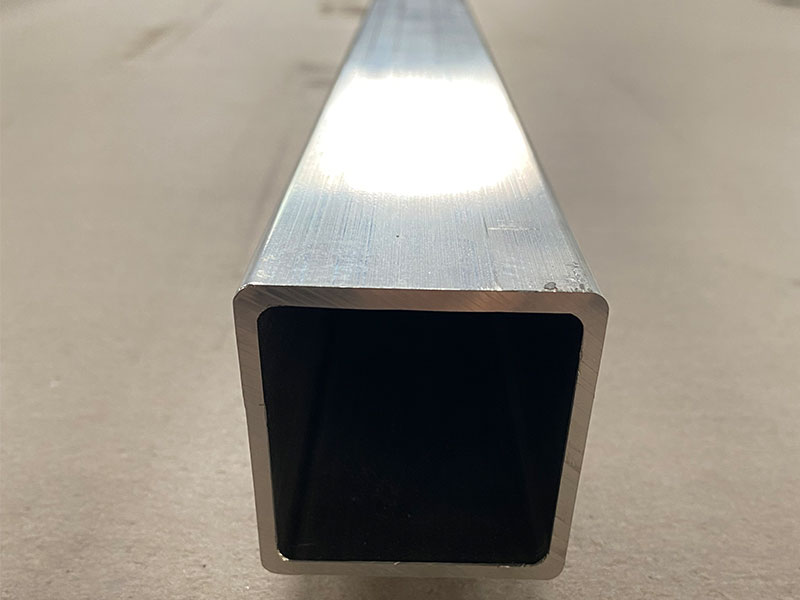

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsMarine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View DetailsRelated Blog

5052 Marine Aluminum Tubes for High Performance Boat Structures

When it comes to high-performance boat structures, the strength, weight, and durability of materials matter enormously. One of the most favored materials in the marine industry is **5052 Marine Aluminum Tubes.

View Details5052 Marine Aluminum Tubes for Shipbuilding Engineering Parts

In the demanding world of shipbuilding engineering, materials are constantly put to the test by harsh marine environments. Among the myriad of metals options, 5052 Marine Aluminum Tubes is know for their remarkable balance of strength.

View Details5052 Marine Aluminum Tubes for Boat and Ship Building

Marine aluminum has proven to be an ideal material for boat and ship building due to its property of being lightweight, corrosion-resistant, and high strength. Among the various alloys available.

View Details5052 Marine Aluminum Tubes for Heavy Duty Marine Applications

When durability, corrosion resistance, and strength are paramount in marine environments, 5052 aluminum alloy tubes is know as the premium choice. Specifically engineered to meet the demanding specifications of heavy-duty marine applications.

View Details5052 Marine Aluminum Round Tubes for Marine Applications

5052 Marine Aluminum Round Tubes are widely acclaimed within the marine industry for their excellent corrosion resistance, strength, and outstanding durability in harsh saltwater environments.

View Details5052 Marine Aluminum Tubes for Marine Vessel Hull Construction

When it comes to building resilient marine vessels, selecting the right materials is crucial. One outstanding option is 5052 Marine Aluminum, widely recognized for its excellent corrosion resistance and structural integrity.

View Details

Leave a Message