5052 Marine Aluminum Tubes for Boat and Ship Building

Marine aluminum has proven to be an ideal material for boat and ship building due to its property of being lightweight, corrosion-resistant, and high strength. Among the various alloys available, 5052 marine aluminum tubes is know as one of the favorites for marine applications.

What are 5052 Marine Aluminum Tubes?

5052 marine aluminum tubes are cylindrical sections made from the 5052 aluminum alloy, specifically engineered for maritime conditions. Characterized by its resilience against alkaline solutions and seawater, 5052 alloy tubes are predominantly used where strength and resistance to corrosion are essential.

Features and Functions

Here are some of the vital features of 5052 marine aluminum tubes:

- Corrosion Resistance: Naturally resistant to pitting, which makes it ideal for use in marine environments.

- High Strength-to-Weight Ratio: Offers excellent strength with less weight, enhancing overall buoyancy and fuel efficiency.

- Formability: Can be easily fabricated into various shapes including bends and seamless constructions, essential for complex designs in boat systems.

- Weldability: Provides strong welded joints, ideal for building various structural components and hulls.

Technical Specifications

To ensure the investment in 5052 marine aluminum tubes meets desired expectations, below is a table outlining its chemical composition, properties (depending on temper condition), and technical specifications:

Chemical Composition

| Element | % Composition |

|---|---|

| Aluminum (Al) | 97.25 - 98.70 % |

| Magnesium (Mg) | 2.2 - 2.8 % |

| Chromium (Cr) | 0.15 - 0.4 % |

| Manganese (Mn) | 0.10 % Max Surplus |

| Silicon (Si) | 0.25 % Max |

| Copper (Cu) | 0.10 % Max |

| Iron (Fe) | 0.40 % Max |

| Others | 0.05 % Each |

Mechanical Properties

| Property | Values |

|---|---|

| Yield Strength (MPa) | 193 |

| Ultimate Tensile Strength (MPa) | 262 |

| Elongation (%) | 12 to 20 |

| Hardness (Brinell) | 60 |

| Density (g/cm^3) | 2.68 |

Alloy Tempering Conditions

| Tempering Condition | Description |

|---|---|

| H32 | Solution heat-treated and strain-hardened with slight strength increase. |

| H34 | Strain-hardened with moderate strength property adjustment. |

Applications of 5052 Marine Aluminum Tubes

5052 aluminum tubes are used in a variety of marine applications. Some of the most common include:

- Boat Hulls: 5052 contributes to lightweight and durable hulls, which can handle rough marine conditions without bending or corroding extensively.

- Workboats: Especially useful in industrial marine vehicles that require consistent functionality with significant strength.

- Propulsion Equipment: Barriers and shafts made from 5052 marine tubes ensure longevity and increased flow efficiency for fuel systems.

- Framework: Used in the structural framework of yachts and other marine crafts for above-water and underwater constructions.

- Fenders and Guardrails: Provides structural elements that require repairability and robust handling against surface damage.

Implementation Standards

When selecting materials for performance, adherence to industry standards is essential. 5052 marine aluminum tubes must comply with several industry and military standards. Guidelines include:

- ASTM B209: Specification for aluminum and aluminum-alloy sheet and plate.

- ISO 8624: International standard accounting for exploratory aluminium silos for immediate property standards.

- MIL-DTL-46027: Military specification in regards to aluminum pollution free cadmium coatings.

Related Products

Marine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

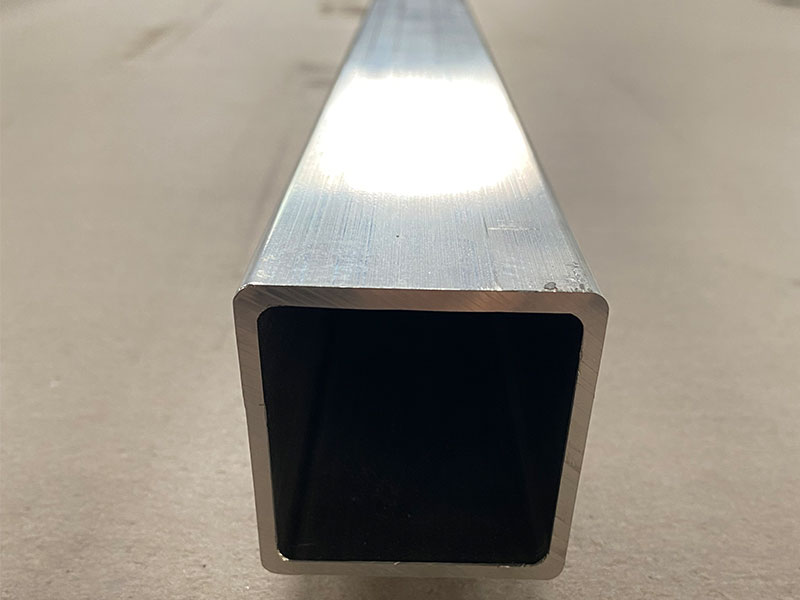

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsMarine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View DetailsRelated Blog

5052 Marine Aluminum Round Tubes for Marine Applications

5052 Marine Aluminum Round Tubes are widely acclaimed within the marine industry for their excellent corrosion resistance, strength, and outstanding durability in harsh saltwater environments.

View Details5052 Marine Aluminum Tubes for Boat and Ship Building

Marine aluminum has proven to be an ideal material for boat and ship building due to its property of being lightweight, corrosion-resistant, and high strength. Among the various alloys available.

View Details5052 Marine Aluminum Tubes for Marine Vessel Hull Construction

When it comes to building resilient marine vessels, selecting the right materials is crucial. One outstanding option is 5052 Marine Aluminum, widely recognized for its excellent corrosion resistance and structural integrity.

View Details5052 Marine Aluminum Tubes for Shipbuilding Engineering Parts

In the demanding world of shipbuilding engineering, materials are constantly put to the test by harsh marine environments. Among the myriad of metals options, 5052 Marine Aluminum Tubes is know for their remarkable balance of strength.

View Details5052 Marine Aluminum Tubes for Heavy Duty Marine Applications

When durability, corrosion resistance, and strength are paramount in marine environments, 5052 aluminum alloy tubes is know as the premium choice. Specifically engineered to meet the demanding specifications of heavy-duty marine applications.

View Details

Leave a Message