5083 marine grade aluminium plate for ship building

5083 Marine Grade Aluminium Plate: The Backbone of Modern Shipbuilding

When it comes to building durable, efficient, and lightweight vessels, 5083 marine grade aluminium plate stands out as a premier material choice. It’s not just another metal; it’s a meticulously engineered alloy tailored for the mariner’s world.

What Makes 5083 Aluminium Plate Special in Shipbuilding?

5083 aluminium is a non-heat-treatable alloy primarily made of aluminium, with magnesium (between 4.0% to 4.9%) as the principal alloying element, along with traces of manganese and chromium. This combination affords it exceptional properties ideal for the harsh maritime environment:

Exceptional Corrosion Resistance: Even in saltwater conditions, where steel quickly succumbs to rust, 5083 offers remarkable resistance against corrosion and oxidization. The magnesium element enhances this capacity, forming a self-protective oxide layer that prevents deterioration. This property drastically reduces maintenance costs and extends the ship’s lifecycle.

Superior Strength-to-Weight Ratio: With a tensile strength ranging approximately from 290 to 345 MPa (megapascals) depending on temper, 5083 strikes an excellent balance between strength and lightness. It's light relative to steel or other metals commonly used before aluminium alloys came into the ship-building arena. This attribute improves fuel efficiency and overall vessel performance thanks to decreased hull weight.

Outstanding Weldability: Heavy fabrication processes are essential in shipbuilding - cutting, shaping, and most importantly, welding large sections of plate into what becomes the hull. 5083 marine grade plate exhibits excellent weld fusion characteristics, ensuring strong joints without weakening nearby areas. Unlike other high-strength metals, it doesn't require post-weld heat treatment to regain mechanical properties—a practical time-saver in shipyards.

Solid Formability: Beyond top-tier welds, 5083 shows ductility and workability, allowing shipbuilders to erect complex curved hulls or specialties like high-speed craft and offshore support vessels. It makes this aluminium variant ideally suited for extruding, rolling, or bending processes without suffering cracks or structural flaws.

How Is 5083 Marine Aluminium Plate Used in Shipbuilding?

The applications of 5083 marine grade aluminium in vessels are extensive, mainly targeting components subjected to direct marine exposure and structural strain:

Hull Construction: The primary and arguably most critical application is in fabricating the hull plating of commercial ships, patrol boats, passenger ferries, and naval vessels. The strength and longevity paired with weight savings help maintain structural integrity while preserving valuable payload capacities.

Decks and Superstructures: Reducing top-level weight is critical in ships to maintain stability and safety. 5083 aluminium is used extensively in decks, coastal cranes’ foundations, and superstructure plates above the hull to enhance agility without compromising overall strength.

Fuel and Water Tanks: Resistance to corrosion and the contamination risk posed by other materials favor 5083 plates in building internal tanks—offering peace of mind when carrying potable water or volatile fuels.

Offshore and Subsea Equipment: Offshore platforms operate in relentlessly saline and challenging conditions. 5083 is used for equipment skids, brackets, and structural frames needing to withstand these challenges without succumbing rapidly to atmospheric or saltwater corrosion.

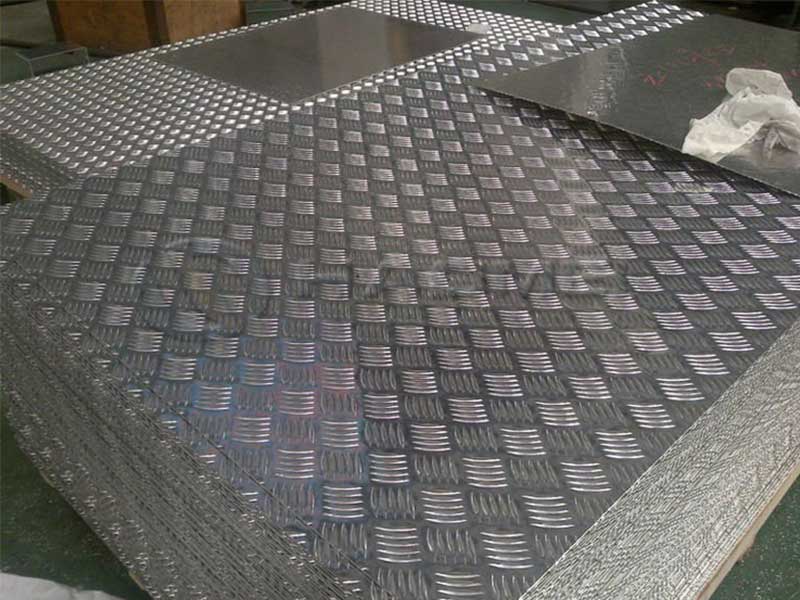

Ship Components: Apart from major structures, this grade is used in material fabrication for stairs, flooring, hatches, and bulwarks—areas where toughness and durability cannot be compromised.

Technical Specifications of 5083 Marine Aluminium

Knowing the tempers (mechanical processing states) can deepen :

- O temper: Fully annealed offering highest ductility but the lowest strength.

- H116/H321 tempers: Often chosen in marine environments for better strength plus enhanced resistance after welding.

- H112: Mainly supplied as pre-hardened plates for demanding structural uses without annealing.

In terms of physical characteristics:

| Property | Typical Value |

|---|---|

| Density | 2.66 g/cm³ (much lighter than steel) |

| Tensile Strength | 275-345 MPa (depending on temper) |

| Yield Strength | 125-215 MPa |

| Elongation at Break | 10-20% (good ductility) |

| Modulus of Elasticity | 70 GPa |

| Corrosion Resistance | Excellent against seawater and marine atmosphere |

These details explain why 5083 marine block structures endure multidirectional loading while withstanding multifarious corrosion drivers.

Why 5083 Outperforms Alternative Materials?

While steel remains popular for ship hulls decades ago, its liability — heavy weight and rust sensitivity — triggered innovation. Historically costly paint coatings or cathodic protection were the remedies but didn’t eliminate degradation threats.

On the other hand, typical aluminium alloys with low corrosion resistance fail under saltwater exposure due to pitting or exfoliation corrosion. The specially balanced chemistry in 5083 marine plate mitigates exactly these issues by maximizing magnesium content, enhancing passive layer durability and nucleating grain structure.

Also, compared to alternative marine-grade alloys such as 5052 or 6061, 5083 achieves the perfect careful tradeoff between strength, corrosion resistance, and workability, making it an indispensable tool in modern maritime engineering.

Related Products

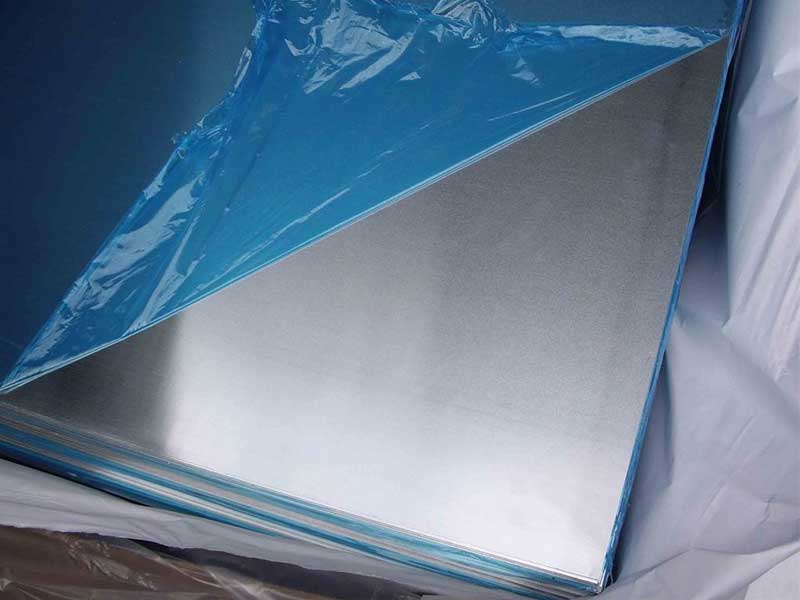

Marine 5083 aluminum plate

Marine 5083 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys and is classified as a non-heat-treatable alloy. Its high magnesium content (typically 4.0–4.9%) enhances its corrosion resistance, especially against seawater-related degradation such as pitting and stress corrosion cracking.

View DetailsMarine 5383 aluminum plate

The 5383 aluminum alloy belongs to the 5xxx series of aluminum-magnesium alloys known for remarkable resistance to marine corrosion and high strength.

View DetailsMarine 5052 aluminum plate

Marine 5052 Aluminum Plate is noted for its exceptional resistance to corrosion caused by seawater, salt spray, and marine atmospheres.

View DetailsMarine 5059 aluminum plate

Marine 5059 Aluminum Plate is distinguished by its high magnesium content and carefully balanced alloying elements, designed to maximize strength without compromising corrosion resistance.

View DetailsMarine aluminum steel clad plate

Aluminum / Steel Clad Plates consist of a sandwich construction in which a layer of marine-grade aluminum alloy is metallurgically bonded to a steel substrate.

View DetailsMarine 5086 aluminum plate

5086 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys. Its hallmark is a high magnesium content—generally between 4.0% and 4.9%—which delivers enhanced corrosion resistance, particularly against saltwater and marine atmospheric conditions.

View DetailsRelated Blog

Marine Grade Aluminum Alloy Plate 5083 H111 H112

When we think of maritime applications, the materials we choose are of utmost importance, and few fulfill the criteria for durability, resistance, and lightweight characteristics better than Marine Grade Aluminum Alloy 5083 H111 and H112.

View Details5083 H111 H112 Aluminium Alloy plate untuk Boat

Temukan keunggulan pelat aluminium 5083 H111 dan H112 untuk aplikasi kapal. Pelajari spesifikasi teknis, sifat kimia, tempering, standar implementasi, serta alasan utama pemilihannya di industri laut.

View DetailsMarine Aluminum Alloy Plate 5052 5083 6061

Marine environments pose extreme challenges—constant exposure to saltwater corrosion, mechanical stresses, and environmental fluctuations demand materials that combine strength, durability, and corrosion resistance.

View DetailsMarine Grade 5083, 5082 Aluminum Alloy Sheet Plate

When it comes to materials that perform exceptionally under the harsh conditions of marine environments, Marine Grade aluminum alloys like 5083 and 5082 hold a revered place in the industry’s toolkit.

View Details7.5 mm marine grade 5083 h16 h22 aluminium sheet plate

Marine environments are notoriously harsh, subjecting materials to saltwater corrosion, mechanical stress, and temperature fluctuations. Among the materials engineered to withstand these conditions, 7.

View Details3mm 5083 Marine Grade Aluminum Plate For Ship building

In the demanding world of shipbuilding, materials that combine strength, durability, and corrosion resistance are essential to construct vessels that can withstand harsh marine environments.

View Details

Leave a Message