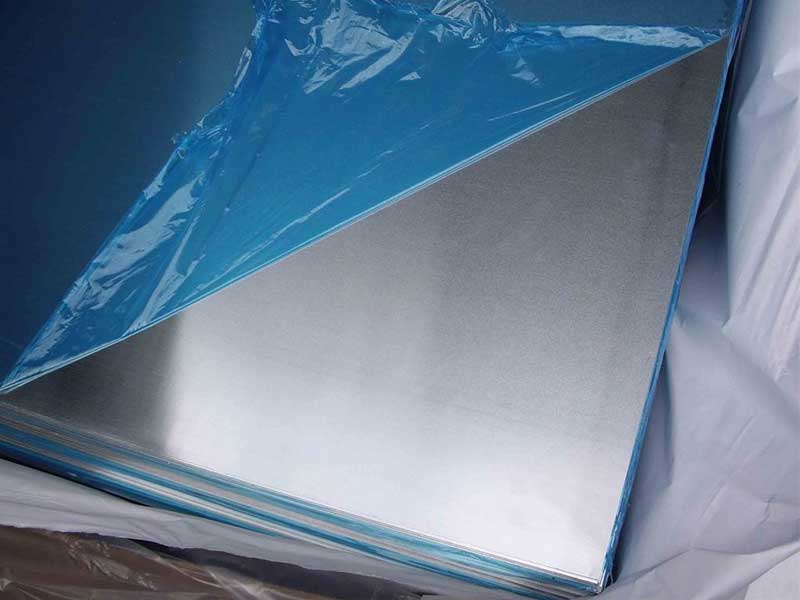

Manufactures aluminum marine alloy plate 5083 5086 o h111 h321

Aluminum marine alloy plates such as 5083 and 5086 are extensively used in maritime applications due to their exceptional corrosion resistance, high strength, and excellent workability. Available in various tempers including O (Annealed), H111 (Strain Hardened and Partially Annealed), and H321 (Strain Hardened and Stabilized), these alloys provide suitable options for different manufacturing and performance requirements in the marine industry.

Features of Aluminum Marine Alloy Plate 5083 & 5086

- Superior Corrosion Resistance: Both alloys resist seawater corrosion, making them ideal for hulls, pontoons, and offshore structures.

- High Strength-to-Weight Ratio: Ensures structural integrity while maintaining lightweight designs.

- Excellent Weldability: Supports a variety of joining methods, vital for large fabrications in shipbuilding.

- Good Workability: Tempers like O and H111 offer good formability, while H321 provides enhanced strength through final stabilization.

- Good Fatigue Performance: Suitable for dynamic marine environments and components subjected to cyclic loads.

Chemical Composition

| Element | 5083 (%) | 5086 (%) | Standard Limits (5083) | Standard Limits (5086) |

|---|---|---|---|---|

| Aluminum (Al) | Balance | Balance | Balance | Balance |

| Magnesium (Mg) | 4.0 - 4.9 | 3.5 - 4.5 | 4.0 - 4.9 | 3.5 - 4.5 |

| Manganese (Mn) | 0.4 - 1.0 | 0.3 - 1.0 | 0.4 - 1.0 | 0.3 - 1.0 |

| Iron (Fe) | ≤ 0.4 | ≤ 0.5 | ≤ 0.4 | ≤ 0.5 |

| Chromium (Cr) | 0.05 - 0.25 | ≤ 0.25 | 0.05 - 0.25 | ≤ 0.25 |

| Copper (Cu) | ≤ 0.1 | ≤ 0.1 | ≤ 0.1 | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.25 | ≤ 0.25 | ≤ 0.25 | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 | ≤ 0.2 | ≤ 0.15 | ≤ 0.2 |

| Others | < 0.15 sum | < 0.15 sum | < 0.15 sum | < 0.15 sum |

Mechanical Properties

| Property | 5083 - O | 5083 - H111 | 5083 - H321 | 5086 - O | 5086 - H111 | 5086 - H321 |

|---|---|---|---|---|---|---|

| Tensile Strength (MPa) | 275 - 320 | 280 - 340 | 295 - 345 | 265 - 305 | 275 - 320 | 280 - 330 |

| Yield Strength (MPa) | 125 - 145 | 150 - 215 | 215 - 245 | 125 - 160 | 145 - 195 | 165 - 215 |

| Elongation (%) | 18 - 22 | 12 - 18 | 10 - 15 | 18 - 22 | 14 - 20 | 12 - 17 |

| Hardness (HB) | 45 - 60 | 60 - 80 | 70 - 90 | 45 - 60 | 60 - 75 | 65 - 85 |

Technical Specifications

| Parameter | Typical Value |

|---|---|

| Density | 2.66 - 2.69 g/cm³ |

| Melting Point | Approx. 608 - 650 °C |

| Thermal Conductivity | ≈ 121-130 W/m·K |

| Electrical Conductivity | ~28-35 % IACS |

| Modulus of Elasticity | 70 GPa |

| Poisson's Ratio | ~0.33 |

Common Tempers and Their Characteristics

| Temper | Description | Typical Use Case |

|---|---|---|

| O | Annealed (soft and ductile) | Forming, rolling, easy weldability and bending |

| H111 | Strain hardened, partially annealed | Moderate strength and workability including marine decks |

| H321 | Strain hardened and stabilized | Higher strength applications requiring improved fatigue life |

Applications of Aluminum Marine Alloy Plates 5083 & 5086

1. Ship and Boat Building

- Hull plates, decks, bulkheads in pleasure crafts, patrol vessels, commercial ships.

- Aluminum marine plates reduce overall weight improving fuel efficiency.

2. Offshore Oil Platforms and Structures

- Support beams, walking decks, crane booms on offshore rigs due to high corrosion resistance.

3. Transportation

- Truck and trailer bodies, tankers transporting liquids, containers where strength and anti-corrosiveness are essential.

4. Automotive and Aircraft Components

- Certain highly corrosion resistant automobile components, armor plating, and aircraft floor panels.

5. General Fabrication

- Storage tanks, pressure vessels, and other industrial components subjected to harsh environments.

Aluminum alloy plates 5083 and 5086, particularly in select tempers like O, H111, and H321, deliver strength, corrosion resistance, weldability, and durability needed in harsh marine environments. Their suitable mechanical properties and workability make them an excellent material choice for shipbuilders, offshore engineers, and specialty component fabricators.

By selecting the ideal temper and alloy grade, producers can tailor aluminum marine plates specifically to application requirements — combining lightweight performance with long-term longevity and reliability in demanding maritime contexts.

For inquiries or custom sizing specifications of aluminum marine alloy plates 5083, 5086 in O, H111, H321 tempers, contact our manufacturing specialists today.

Related Products

Marine 5383 aluminum plate

The 5383 aluminum alloy belongs to the 5xxx series of aluminum-magnesium alloys known for remarkable resistance to marine corrosion and high strength.

View DetailsMarine 5052 aluminum plate

Marine 5052 Aluminum Plate is noted for its exceptional resistance to corrosion caused by seawater, salt spray, and marine atmospheres.

View DetailsMarine 5083 aluminum plate

Marine 5083 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys and is classified as a non-heat-treatable alloy. Its high magnesium content (typically 4.0–4.9%) enhances its corrosion resistance, especially against seawater-related degradation such as pitting and stress corrosion cracking.

View DetailsMarine 5059 aluminum plate

Marine 5059 Aluminum Plate is distinguished by its high magnesium content and carefully balanced alloying elements, designed to maximize strength without compromising corrosion resistance.

View DetailsMarine 5086 aluminum plate

5086 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys. Its hallmark is a high magnesium content—generally between 4.0% and 4.9%—which delivers enhanced corrosion resistance, particularly against saltwater and marine atmospheric conditions.

View DetailsMarine heavy duty aluminum plate

Marine Heavy Duty Aluminum Plates Sheets generally refer to thick aluminum alloy plates and heavy gauge sheets produced from marine-grade alloys such as 5083, 5086, 5059, and 5383.

View DetailsRelated Blog

Manufactures aluminum marine alloy plate 5083 5086 o h111 h321

Aluminum marine alloy plates such as 5083 and 5086 are extensively used in maritime applications due to their exceptional corrosion resistance, high strength, and excellent workability.

View DetailsMarine grade aluminium alloy plate 5083 h116 with dnv certification

Marine grade aluminium alloy plate 5083 H116 with DNV certification is a high-strength, corrosion-resistant aluminum alloy plate specifically tailored for shipbuilding and offshore applications.

View DetailsMarine Grade Aluminum Alloy Plate 5083 H111 H112

When we think of maritime applications, the materials we choose are of utmost importance, and few fulfill the criteria for durability, resistance, and lightweight characteristics better than Marine Grade Aluminum Alloy 5083 H111 and H112.

View Details5083 0.5mm aluminum plate sheet for marine

5083 0.5mm aluminum plate sheet is a thin, high-strength marine-grade alloy offering excellent corrosion resistance, good weldability, and superior formability. Ideal for shipbuilding, boat decking, marine fittings, and coastal structures.

View DetailsAluminum Sheet Plate alloy 5083 H111 for boat application

When it comes to manufacturing high-performance boats that demand strength, corrosion resistance, and long-lasting durability, Aluminum Sheet Plate Alloy 5083 H111 stands out as a superior material.

View Details3mm 5083 Marine Grade Aluminum Plate For Ship building

In the demanding world of shipbuilding, materials that combine strength, durability, and corrosion resistance are essential to construct vessels that can withstand harsh marine environments.

View Details

Leave a Message