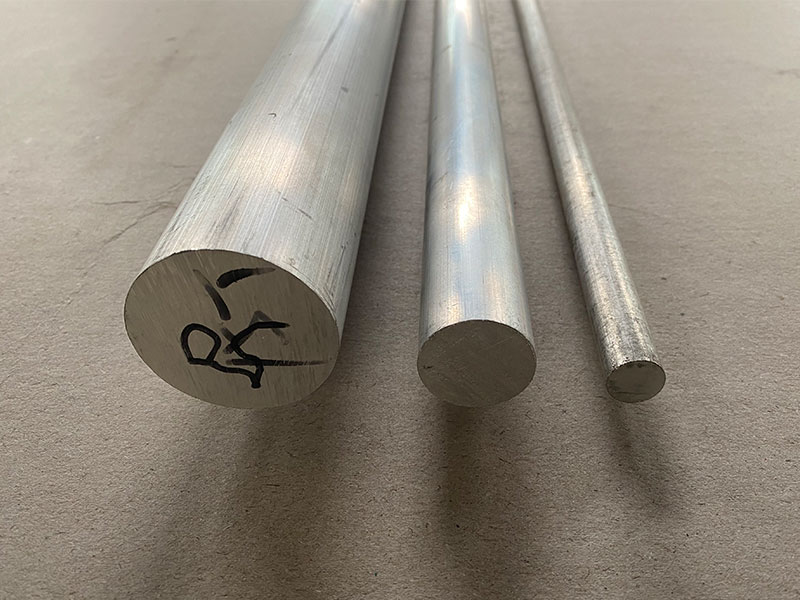

6082 Marine Grade Aluminum Solid Bar for Marine Hull Strengthening

The 6082 Marine grade aluminum solid bar is widely used for reinforcing hull structures, decks, and load‑bearing components in ships and offshore vessels. It combines high strength, excellent corrosion resistance, and good weldability, making it a reliable choice for both new builds and refit projects.

6082 is a heat‑treatable aluminum‑magnesium‑silicon alloy in the 6xxx series. It is often chosen as a stronger alternative to 6061, especially where higher load capacity and better structural stiffness are needed.

|--------------------------|-------------------------------------------------------------------------|| Alloy series | 6xxx (Al-Mg-Si) || Temper options | T6, T651, T5 (others on request) || Primary attributes | High strength, good corrosion resistance, good weldability || Typical marine use | Hull strengthening, frames, stiffeners, brackets, deck supports || Form supplied | Solid round bar, square bar, custom-cut blocks || Standards (typical) | EN AW-6082 / AA 6082, ASTM B211/B221 (equivalents may apply) |

Chemical Composition of 6082 Aluminum

The performance of 6082 comes from its controlled Al–Mg–Si chemistry with manganese additions for improved strength and grain structure.

| Element | Typical Range (%) | Function in Alloy |

|---|---|---|

| Silicon (Si) | 0.70 – 1.30 | Forms Mg₂Si for precipitation hardening, strengthens alloy |

| Magnesium (Mg) | 0.60 – 1.20 | strengthening element, improves work hardening |

| Manganese (Mn) | 0.40 – 1.00 | Refines grain structure, enhances strength and toughness |

| Iron (Fe) | ≤ 0.50 | Controlled to limit inclusions, helps maintain toughness |

| Zinc (Zn) | ≤ 0.20 | Minor impurity, kept low for corrosion control |

| Copper (Cu) | ≤ 0.10 | Limited to preserve corrosion resistance |

| Chromium (Cr) | ≤ 0.25 | Supports corrosion resistance and stability |

| Titanium (Ti) | ≤ 0.10 | Grain refiner during casting |

| Others (each) | ≤ 0.05 | Trace elements, tightly controlled |

| Others (total) | ≤ 0.15 | |

| Aluminum (Al) | Balance | Base metal |

Note: Actual composition may vary slightly with specific standards and mill practices.

Mechanical Properties and Technical Specifications

Typical Mechanical Properties (T6 / T651 Temper)

6082-T6/T651 bar is widely used where high strength is required in marine reinforcement.

| Property | Typical Value (T6/T651) | Test Direction | Notes |

|---|---|---|---|

| Tensile strength, Rm | 290 – 340 MPa | Longitudinal | Higher than 6061 in most conditions |

| 0.2% Proof stress, Rp0.2 | 240 – 280 MPa | Longitudinal | Reliable for structural design calculations |

| Elongation (A50) | 8 – 12 % | Longitudinal | Good ductility for forming and impact loading |

| Brinell hardness (HBW) | 90 – 100 | – | Indicates good wear and indentation resistance |

| Modulus of elasticity, E | ~70 GPa | – | Similar to other Al alloys |

| Shear strength (approx.) | ~0.6 × Rm | – | For shear webs and brackets |

| Density | ~2.70 g/cm³ | – | About one‑third the density of steel |

Typical Size Range and Supply Conditions

| Parameter | Availability Range / Options |

|---|---|

| Diameter (round bar) | Approx. 8 mm – 300+ mm |

| Square / flat bar | Common from 10 × 10 mm to 300 × 300 mm (custom on request) |

| Lengths supplied | Standard 3 m, 4 m, 6 m; custom cut‑to‑length possible |

| Tolerances | As per EN / ASTM standards or tighter precision if specified |

| Surface condition | Mill finish, peel‑turned, or machined; optional anodizing/coating |

| Tempers | T6, T651 (stress-relieved), T5 for special forming requirements |

Corrosion Resistance in Marine Environments

6082 is well suited for saltwater exposure, especially above the waterline and in splash zones, where a combination of strength and corrosion resistance is critical.

| Corrosion Aspect | Performance of 6082 Marine Bar |

|---|---|

| General seawater resistance | Good, especially with proper design and maintenance |

| Pitting / crevice corrosion | Good when exposed surfaces are clean and drained |

| Stress corrosion cracking | Better than many high‑copper or high‑strength alloys |

| Galvanic compatibility | Compatible with most Al alloys; avoid direct contact with stainless and carbon steels without isolation |

| Surface protection | Anodizing, marine paints, sealants further extend life |

For long‑term marine hull strengthening, it is common to combine correct alloy selection (6082), proper joint design, insulation from dissimilar metals, and protective coatings.

Welding and Fabrication Characteristics

Good weldability is a major advantage of 6082 over higher‑strength, copper‑rich alloys.

| Fabrication Aspect | 6082 Performance and Notes |

|---|---|

| Weldability | Good with MIG/TIG; 5xxx fillers (e.g., 5356) commonly used |

| Post‑weld strength | Strength in heat‑affected zone drops from T6; design accordingly |

| Machinability | Good in T6/T651; chips break cleanly, suitable for CNC |

| Forming / bending | Better in softer tempers; tighter radii require T4/T5 or warm forming |

| Heat treatment | Solution heat‑treatable and artificially aged |

When used in hull strengthening, designers often oversize welded sections slightly to compensate for local strength reduction in weld zones.

Features for Marine Hull Strengthening

Structural Performance

| Feature | Benefit for Hull Strengthening |

|---|---|

| High strength‑to‑weight ratio | Enables lighter reinforcement compared with steel |

| Good stiffness (E ≈ 70 GPa) | Helps control hull deflection and vibration |

| Consistent mechanical values | Reliable for finite element and rules‑based design |

| Thick‑section availability | Suitable for large frames, girders, and high‑load brackets |

Durability and Service Life

| Durability Factor | Relevance to Marine Use |

|---|---|

| Saltwater corrosion resistance | Reduces risk of section loss and unplanned repairs |

| Fatigue resistance | Important for cyclic wave and engine‑induced loading |

| Compatibility with coatings | Accepts marine primers, paints, and anodized finishes |

Installation and Maintenance

| Aspect | 6082 Solid Bar Advantage |

|---|---|

| Ease of cutting and machining | Shortens fabrication lead time on shipyard schedule |

| Reliable welding behavior | Suitable for on‑board retrofits and repairs |

| Low maintenance requirement | Long intervals between inspections when properly designed |

Typical Marine Applications

6082 Marine grade aluminum solid bar is widely used across vessel types: workboats, patrol craft, high‑speed ferries, yachts, and offshore support vessels.

Structural Hull Components

| Component Type | Use of 6082 Solid Bar |

|---|---|

| Longitudinal stiffeners | Reinforcing bottom and side shell to limit panel buckling |

| Transverse frames | Improving hull shape stability and impact resistance |

| Keel and centerline members | Local reinforcement around high‑load longitudinal areas |

| Bulkhead edge stiffeners | Enhancing watertight bulkhead integrity |

| Deck and superstructure ribs | Strengthening deck panels, walkways, and platform supports |

Local Reinforcements and Fittings

| Area / Equipment | Example Applications with 6082 Bar |

|---|---|

| Engine foundation zone | Bedplate stiffeners, vibration support frames |

| Deck machinery foundations | Winch, capstan, crane, and windlass mounting structure |

| Mooring / towing points | Bollard bases, chock reinforcements, fairlead supports |

| Ramp and door frames | Ramp hinge supports, door frames, coaming reinforcements |

| Mast / radar supports | Compression posts, brackets, and radar arch reinforcement |

In many designs, solid bar sections are combined with plates and extruded profiles to form hybrid structures, achieving both strength and efficient material use.

Comparison with Other Marine Aluminum Alloys

Selecting 6082 is often about finding the right balance between strength, weldability, and toughness.

| Alloy | Relative Strength | Weldability | Corrosion Resistance | Typical Marine Use |

|---|---|---|---|---|

| 5083 (Al-Mg) | High (non‑heat treatable) | Excellent | Excellent in seawater | Hull plating, tanks, general structure |

| 6082 (Al-Mg-Si) | High (heat treatable) | Good | Very good | Hull reinforcement, frames, stiffeners, machined parts |

| 6061 (Al-Mg-Si) | Medium‑high | Good | Good | General structures, fittings, non‑critical frames |

| 7075 (Al-Zn-Mg-Cu) | Very high | Limited | Moderate | High‑strength components away from seawater, aerospace bias |

For hull strengthening where both strength and welding are essential, 6082 is often preferred over 7075 and used alongside 5083 plate.

Design and Procurement Considerations

When specifying 6082 Marine grade aluminum solid bar for a project, consider the following parameters:

| Design / Purchase Parameter | Recommendation |

|---|---|

| Temper selection | T6 or T651 for structural strength; discuss weld zones in design |

| Diameter / section size | Match to calculated loads and ship classification rules |

| Certification | Request mill certificates; class approvals if required |

| Surface preparation | Plan for cleaning, anodizing, or painting as per service environment |

| Joining methods | Define welding procedure specs (WPS) and filler type early |

| Integration with other materials | Include galvanic isolation where steel and aluminum meet |

6082 Marine grade aluminum solid bar delivers a robust combination of strength, corrosion resistance, and fabrication flexibility. For marine hull strengthening, it offers:

- Strong, lightweight reinforcement compared with traditional steel

- Reliable performance in seawater when properly protected

- Good weldability and machinability for both new construction and refit

By carefully selecting temper, dimensions, and protective systems, naval architects and shipyards can use 6082 solid bar to build stiffer, lighter, and more durable hull structures across a wide range of marine vessels.

Related Products

Marine aluminum hollow bars

Marine Grade Aluminum Hollow Bars are fabricated from high-quality alloys such as 5083, 5052, 6061, and 6082, all known for their exceptional resistance to seawater corrosion, salt spray, and marine atmospheres.

View DetailsMarine aluminum hexagonal bars

Marine Grade Aluminum Hexagonal Bars are produced from premium corrosion-resistant aluminum alloys such as 5083, 5052, 6061, and 6082.

View Details6082 marine aluminum rod & bar

6082 Aluminum Rods & Bars are extruded or rolled products manufactured from 6082 aluminum alloy — a thermally treated (typically T6 temper) aluminum-magnesium-silicon alloy that balances high tensile strength, good weldability, and excellent corrosion resistance.

View DetailsMarine grade aluminum solid bar

Marine Grade Aluminum Solid Bars are produced from premium aluminum alloys optimized for saltwater exposure, such as 5083, 5052, 6061, and 6082. These alloys offer unparalleled resistance to corrosion caused by seawater, salt spray, and marine atmospheres, while maintaining excellent mechanical strength and toughness.

View DetailsRelated Blog

6082 Marine Aluminum Hollow Bars for Custom Boat Frame Solutions

6082 Marine Aluminum Hollow Bars for Custom Boat Frame Solutions In modern boatbuilding, frame design has evolved from heavy, overbuilt structures to lightweight, precision-engineered systems.

View Details6082 Marine Aluminum Bar for High Strength Marine Components

In the demanding world of marine engineering, the choice of materials defines not only the longevity but also the safety and performance of vessels. Among the plethora of metal options.

View Details6082 Marine Grade Aluminum Solid Bar for Boat Deck Reinforcements

When it comes to marine vessel construction and refurbishment, selecting the right materials is vital for ensuring durability, performance, and safety. Among various options.

View Details6082 Marine Aluminum Bar for Custom Boat Fabrication and Reinforcement

When it comes to custom boat fabrication and structural reinforcement in marine environments, material choice is paramount. The 6082 Marine Aluminum Bar stands out as a superior solution that combines strength, corrosion resistance.

View Details6082 Marine Grade Aluminum Solid Bar for Saltwater Resistant Marine Parts

The 6082 marine grade aluminum solid bar is a high‑strength, corrosion‑resistant alloy widely used for structural components in harsh marine environments. It offers an excellent balance of strength, workability, and long‑term durability, maki.

View Details6082 Marine Grade Aluminum Solid Bar for Marine Hull Strengthening

The 6082 marine grade aluminum solid bar is widely used for reinforcing hull structures, decks, and load‑bearing components in ships and offshore vessels. It combines high strength, excellent corrosion resistance, and good weldability, .

View Details

Leave a Message