6082 Marine Aluminum Round Tubes for Offshore Construction

In the demanding arena of offshore construction, selecting materials that combine strength, corrosion resistance, and manufacturability is crucial for ensuring durability and safety. Among such materials, 6082 Marine Aluminum round tubes have emerged as a preferred solution, admired for their excellent performance under harsh marine conditions.

Why 6082 Aluminum is Ideal for Marine Environments

6082 is part of the 6xxx series aluminum alloys, prized for their medium-to-high strength and superb corrosion resistance. The marine-grade version of 6082 is especially crafted to withstand chloride-induced corrosion prevalent offshore. The latest formulations and alloying methods optimize this alloy for tubular structures used in platforms, pipelines, and other underwater fixtures.

advantages:

- Excellent corrosion resistance: Impedes pitting in seawater.

- High strength-to-weight ratio: Reduces structural dead-weight.

- Superior weldability: Enables joining without losing mechanical integrity.

- Good machinability: Facilitates advanced fabrication processes.

- Good formability and surface finish: Allows utilization in aesthetic exposed members.

Chemical Composition

The uniqueness of 6082 aluminum lies in its controlled alloy composition, balancing mechanical properties and corrosion resistance:

| Element | Typical Range (wt%) |

|---|---|

| Aluminum | Balance |

| Magnesium | 0.6 - 1.2 |

| Silicon | 0.7 - 1.3 |

| Manganese | 0.4 - 1.0 |

| Iron | ≤ 0.5 |

| Chromium | ≤ 0.25 |

| Copper | ≤ 0.1 |

| Zinc | ≤ 0.2 |

| Others (each) | ≤ 0.05 |

| Others (total) | ≤ 0.15 |

This blend ensures the alloy develops a robust magnesium silicide phase (Mg2Si), which accounts for its enhanced strength and corrosion resistance.

Mechanical Properties and Temper Conditions

The strength and hardness of 6082 aluminum significantly depend on its temper:

| Temper | Description | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|---|

| T6 | Solution Heat Treated + Artificially Aged | 280 – 310 | 260 – 280 | ≥8 |

| T651 | Stress Relieved after T6 | 280 – 310 | 260 – 280 | ≥8 |

The T6 temper enhances strength via precipitation hardening, a process involving solution treatment—a dissolution of phases at high temperatures—followed by controlled aging at moderate temperatures, developing finely distributed strengthen precipitates in the microstructure. The T651 temper also relieves residual stress caused by mechanical processes like extrusion or cold working, preventing premature dimensional changes.

Implementation Standards and Industry Compliance

Reliable performance in offshore construction requires adherence to strict standards. 6082 marine aluminum round tubes typically meet or exceed:

- ASTM B221: Specification for aluminum and aluminum-alloy extruded bars, rods, wire, profiles, and tubes.

- EN 755-2 / EN 10204: European standards defining aluminum alloys and tempers suitable for structural and marine applications.

- ISO 6362: Chemical composition and mechanical property limits for wrought aluminum alloys.

- ASME B31.3: For applicable offshore piping requirements.

Certificates of analysis (CoA) and third-party inspections ensure compliance to these standards, verifying dimensional tolerances, material properties, and surface quality crucial for subsea installations.

Specialized Functions in Offshore Construction

The function of 6082 Marine aluminum round tubes integrates the alloy’s inherent properties into various offshore applications:

- Structural Supports: Lightweight yet highly stressed tubular frameworks on oil rigs and wind turbine installations require durable tubes that resist fatigue and seawater insult.

- Pipeline Segments: Used as protective casings for subsea electrical conduits and flow lines, benefiting from corrosion resistance and machinability.

- Buoyancy Elements: Precisely dimensioned hollow tubes integrated into flotation and mooring systems serve multifunctional roles of strength and buoyancy.

- Corrosion Resistant Hydraulic Components: Many offshore hydraulic systems use 6082 tubes for pressure rated lines due to favorable toughness combined with corrosion resistance.

Corrosion Resistance Benchmarking

Among aluminum marine grades, 6082 balances corrosion resistance and mechanical strength. The alloy forms a stable protective oxide film (Al2O3) that withstands oxidative degradation. Moreover, the manganese and chromium additions contribute secondary protective effects. Maintaining this passive layer integrity is critical — as acidic or highly alkaline offshore environments can deteriorate inadequate alloys more rapidly.

Through controlled composition, manufacturing, and tempering, 6082 tubes maintain exceptional integrity in chloride-laden atmospheres, siding favorably against both carbon steel and 5xxx marine aluminum alloys prone to localized corrosion or embrittlement.

Dimensional Parameters and Fabrication Options

Marine aluminum round tubes made from 6082 alloy are offered across a broad dimension spectrum to meet various structural needs. Common specifications include tube wall thickness ranging from 2 mm to 25 mm and diameters from approximately 20 mm to 400 mm, customizable upon request.

These tubes can be extruded, heat-treated, straightened, and surface treated (anodized or powder coated) based on rugged offshore requirements.

Related Products

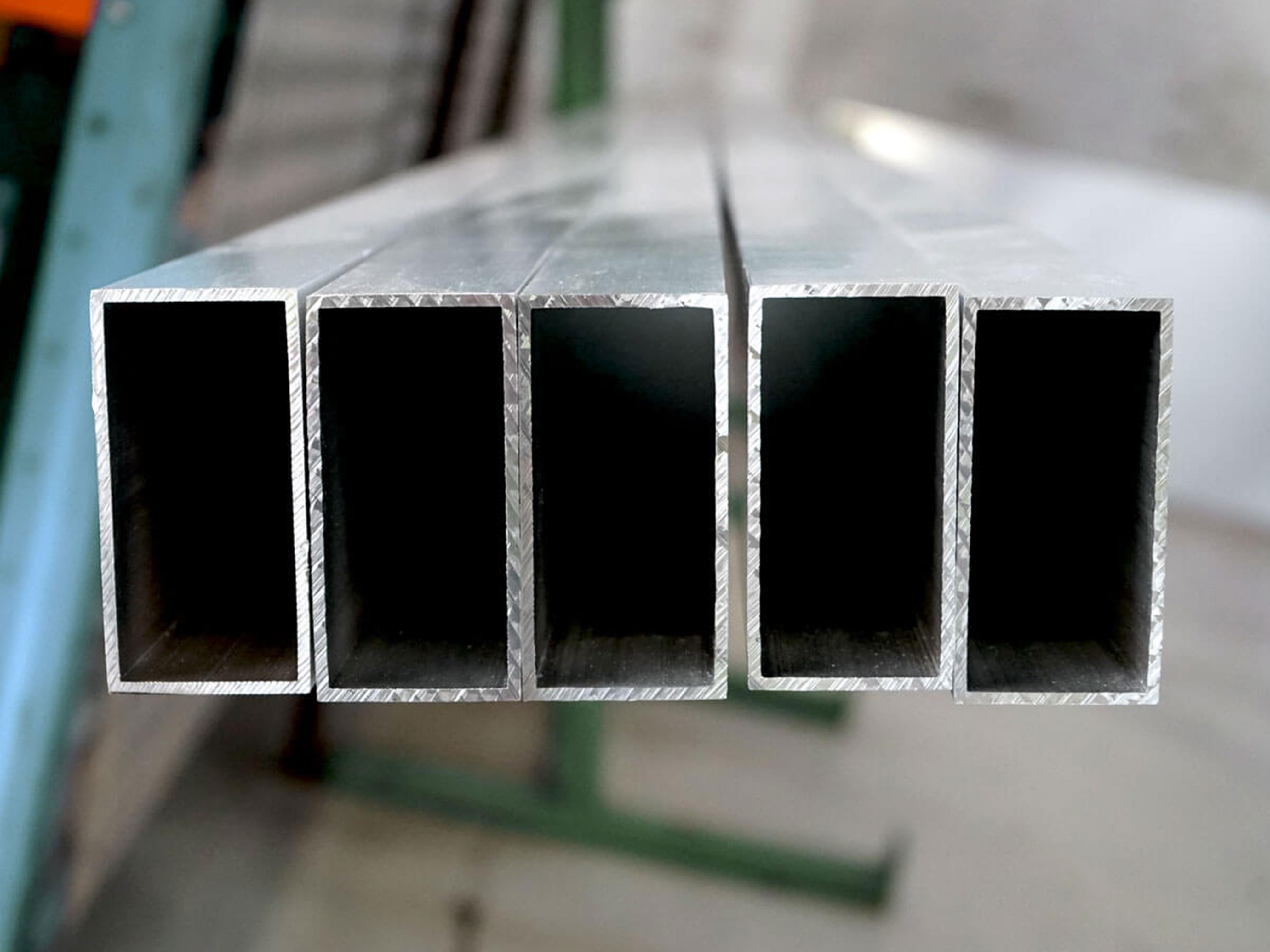

Marine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View DetailsMarine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsRelated Blog

6082 Marine Aluminum Tubes for Saltwater Exposure Resistant Boats

Advantages of 6082 marine aluminum tubes, specifically engineered for saltwater exposure resistant boats. Learn about their chemical composition, mechanical properties, tempering conditions, implementation standards, and why they are the optimal choice in

View Details6082 Marine Aluminum Tubes for Marine Engine Component Support

The 6082 marine aluminum tubes are a premium-grade aluminum alloy offering a balanced blend of strength, corrosion resistance, and excellent machinability.

View Details6082 Marine Aluminum Square Tubes for Corrosion Resistant Projects

When it comes to constructing structures that demand impeccable resistance to corrosion in harsh marine environments, 6082 marine aluminum square tubes is know as an industry favorite.

View Details6082 Marine Aluminum Round Tubes for Offshore Construction

In the demanding arena of offshore construction, selecting materials that combine strength, corrosion resistance, and manufacturability is crucial for ensuring durability and safety.

View Details

Leave a Message