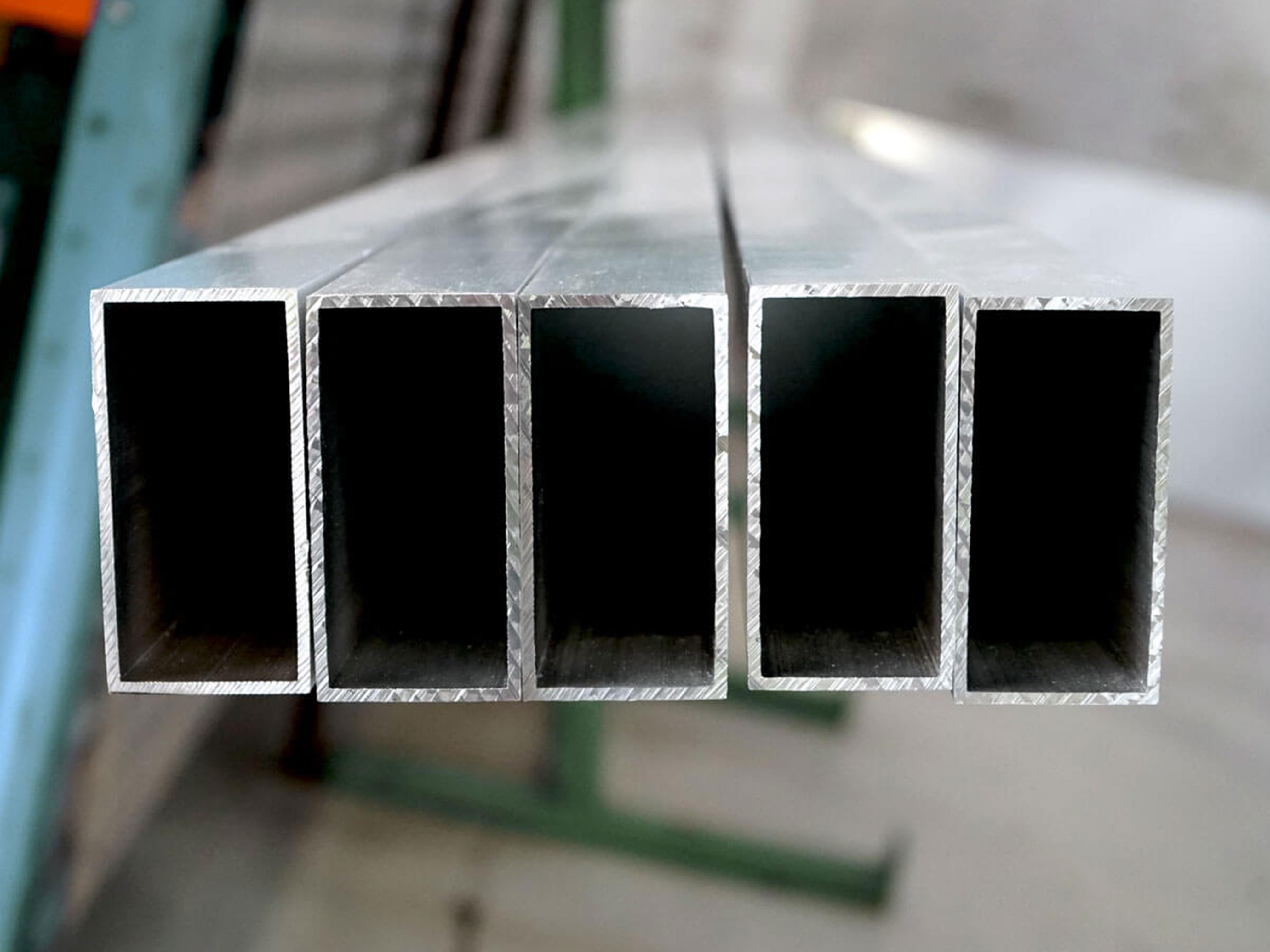

6082 Marine Aluminum Square Tubes for Corrosion Resistant Projects

When it comes to constructing structures that demand impeccable resistance to corrosion in harsh marine environments, 6082 marine aluminum square tubes is know as an industry favorite.

6082 Marine Aluminum: More Than Just Alloy Composition

6082 is a part of the 6xxx series aluminum alloys, primarily known for combining excellent mechanical strength with great corrosion resistance. It contains alloying elements like silicon and magnesium, which contribute to the formation of a robust magnesium-silicide phase. This phase enhances both its strength and its ability to withstand harsh environments without succumbing to corrosion.

Our experience with 6082 marine aluminum square tubes in corrosion-resistant projects highlights their excellent strength-to-weight ratio as a advantage. We've seen them perform exceptionally well in marine environments, particularly in applications like boat frames, railings, and dock structures. However, proper surface preparation is paramount. We've learned that inconsistent pre-treatment, even minor inconsistencies, can lead to localized corrosion despite the alloy's inherent resistance. A meticulous cleaning process followed by a high-quality anodizing or powder coating is crucial for maximizing the lifespan and maintaining the structural integrity of the finished product. Furthermore, the selection of appropriate fasteners and their correct installation are equally vital; dissimilar metals can trigger galvanic corrosion, negating the advantages of the 6082 alloy itself.

Beyond the material's inherent properties, the specific environmental conditions is critical. We've encountered instances where seemingly minor variations in salinity or exposure to pollutants significantly impacted the longevity of the tubes. For example, projects near industrial areas or those subjected to frequent splashing of polluted water required more robust surface treatments than those in cleaner, less aggressive marine environments. This highlights the importance of a thorough risk assessment before project commencement. We've found that collaborating closely with clients to understand the intended application and the specific challenges of their environment allows us to tailor our recommendations for surface finishes and preventative maintenance strategies, ultimately ensuring the long-term success of the project.

What truly sets marine-grade 6082 aluminum apart, however, is its thoughtfully engineered purity levels and post-processing treatments, specifically tailored for marine conditions. Unlike standard 6082 aluminum, marine aluminum versions often undergo enhanced heat treatment processes and corrosion inhibitors are optimized to resist saltwater effects such as pitting and galvanic corrosion.

Why Choose 6082 Aluminum Square Tubes for Marine Use?

1. Superior Corrosion Resistance

Freshwater, saltwater, humidity, and salt sprays are relentless adversaries to structural materials. But thanks to the 7072 aluminum alloy cladding applied on 6082 marine tubes, their corrosion resistance is significantly boosted. This cladding forms a protective oxide layer that resists penetration of chloride ions—one of the main sources of metal degradation in seawater.

2. Higher Strength-to-Weight Ratio

Marine engineers seek materials that deliver optimal strength without increasing weight—critical for buoyancy and fuel efficiency. The unique chemistry and tempering of 6082 alloy aluminum create an ideal balance of mechanical strength and lightweight construction, with tensile strengths up to 310 MPa (megapascals). This means 6082 square tubes can carry significant loads while allowing vessels or marine structures to remain agile and efficient.

3. Excellent Weldability and Formability

A snorkeling platform, boat frame, or dock structure all require components that can be welded and shaped easily without losing durability or corrosion resistance post-fabrication. 6082 marine aluminum’s balanced chemistry ensures strong weld joints and high formability—expanding design flexibility without trade-offs in performance.

Distinct Benefits of Square Tube Fabrication

Compared to round tubes or flat bars, square tubes offer several advantages in marine applications:

- Uniform Structural Support: The symmetrical shape evenly distributes stresses, making it perfect for framing.

- Screening and Railings: Aesthetically favored for clean geometric profiles.

- Ease of Attachment: Square tubes allow for simpler fastening and joining to other components.

These benefits make 6082 marine aluminum square tubes a preferred structural component in dockworks, marine furniture, lifeboat frames, and floating platforms where corrosion resistance is critical.

Prolonging Marine Project Lifespan: The 6082 Advantage

Adopting 6082 marine aluminum square tubes means investing in long-term reliability. Their resistance to common marine degradation pathways reduces maintenance intervals and replacement frequency. Unlike steel, which corrodes rapidly without costly coatings, 6082 aluminum maintains structural integrity for years under typical marine exposures—protecting budgets and assuring safety.

Related Products

6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View DetailsMarine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View DetailsRelated Blog

6082 Marine Aluminum Tubes for Saltwater Exposure Resistant Boats

Advantages of 6082 marine aluminum tubes, specifically engineered for saltwater exposure resistant boats. Learn about their chemical composition, mechanical properties, tempering conditions, implementation standards, and why they are the optimal choice in

View Details6082 Marine Aluminum Square Tubes for Corrosion Resistant Projects

When it comes to constructing structures that demand impeccable resistance to corrosion in harsh marine environments, 6082 marine aluminum square tubes is know as an industry favorite.

View Details6082 Marine Aluminum Round Tubes for Offshore Construction

In the demanding arena of offshore construction, selecting materials that combine strength, corrosion resistance, and manufacturability is crucial for ensuring durability and safety.

View Details6082 Marine Aluminum Tubes for Marine Engine Component Support

The 6082 marine aluminum tubes are a premium-grade aluminum alloy offering a balanced blend of strength, corrosion resistance, and excellent machinability.

View Details

Leave a Message