6082 Marine Aluminum Tubes for Saltwater Exposure Resistant Boats

Marine environments demand materials that combine strength, corrosion resistance, and durability to withstand harsh conditions typically found during saltwater exposure. 6082 marine aluminum tubes have become a material of choice for constructing boat structures, railings, and framework due to their superior mechanical properties, corrosion resistance and lightweight characteristics.

What Is 6082 Aluminum Alloy?

6082 aluminum belongs to the 6xxx series alloys, primarily composed of magnesium and silicon that impart greater strength compared to other aluminum grades. It is particularly known for an excellent balance between strength and corrosion resistance, making it highly desirable in marine constructions where both properties are critical. This alloy is widely used in manufacturing aluminum tubes designed for structural use in environments subjected to saltwater spray and marine humidity.

Chemical Composition of 6082 Aluminum Alloy

The chemical composition of 6082 marine aluminum tubes is strictly controlled to enhance corrosion resistance and mechanical strength while facilitating weldability and workability. Below is the typical chemical composition range (%) according to the BS EN 573-3 standard:

| Element | Content (%) | Description |

|---|---|---|

| Silicon (Si) | 0.7 – 1.3 | Enhances strength and corrosion resistance |

| Iron (Fe) | 0.0 – 0.5 | Common impurity, limited to preserve ductility |

| Copper (Cu) | 0.0 – 0.1 | Improves strength, low content for corrosion resistance |

| Manganese (Mn) | 0.4 – 1.0 | Improves toughness and corrosion resistance |

| Magnesium (Mg) | 0.6 – 1.2 | Main strengthening element |

| Zinc (Zn) | 0.0 – 0.2 | Minimal, helps control grain growth |

| Titanium (Ti) | 0.0 – 0.1 | Refines grain size and enhances strength |

| Others | 0.0 – 0.15 | Trace elements, controlled tightly |

| Aluminum (Al) | Remainder | Base metal |

Mechanical Properties and Temper Conditions

6082 marine aluminum tubes are available in various heat-treatment tempers, which directly affect mechanical properties such as yield strength, tensile strength, and elongation. The most common tempers suitable for marine applications include:

| Temper Designation | Treatment Description | Typical Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|---|

| O | Fully Annealed (softest condition) | 130 – 185 | 55 – 120 | 18 – 24 |

| T5 | Cooled from elevated temperature shaping followed by artificial aging | 225 – 275 | 150 – 215 | 10 – 15 |

| T6 | Solution heat-treated and artificially aged | 260 – 320 | 230 – 280 | 8 – 12 |

Note: For marine tubes, T5 or T6 tempers are preferred for ensuring required strength and durability without compromising corrosion resistance.

Corrosion Resistance in Saltwater Environments

One of the critical advantages of 6082 marine aluminum on saline conditions is its excellent corrosion resistance. Unlike standard steels which corrode quickly in saltwater without protective coatings, 6082 aluminum benefits from its natural oxide layer. This property helps prevent marine corrosion phenomena such as pitting, crevice corrosion, and galvanic corrosion when used in conjunction with compatible materials like stainless steel.

To maximize corrosion protection:

- Use anodized surface treatments or specialized marine-grade coatings.

- Avoid galvanic coupling with dissimilar metals that aggravate corrosion.

- Implement regular maintenance cycles like rinsing to remove salt deposits.

Implementation Standards and Quality Control

Marine aluminum tubes manufactured from 6082 alloy conform to widely accepted standards that assure quality, strength, and performance, including:

- ISO 6362 – Wrought aluminum and aluminum alloys - Monolithic bars, rods and profiles.

- EN 755 – Aluminum and aluminum alloys — Extruded rod/bar, tube and profiles.

- BS EN 573-3 – Aluminum and aluminum alloys — Chemical composition and forms.

- ASTM B221 – Standard Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes.

Strict quality control measures during extrusion include maintaining dimensional tolerances, surface finish verification, and mechanical testing (tensile, hardness, and corrosion resistance tests).

Applications of 6082 Marine Aluminum Tubes in Boats

Common applications of 6082 marine aluminum tubes in saltwater boats include:

- Boat hull framing and structural reinforcements

- Handling cranes, davits, and marine winches frames

- Railings, guards, and ladders exposed to marine conditions

- Fuel tanks and components requiring corrosion resistance

- Hydraulic pipework and marine lifts

The combination of lightweight properties and excellent resistance to seawater stress significantly enhances a boat’s operational performance and structural longevity.

Related Products

Marine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsMarine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

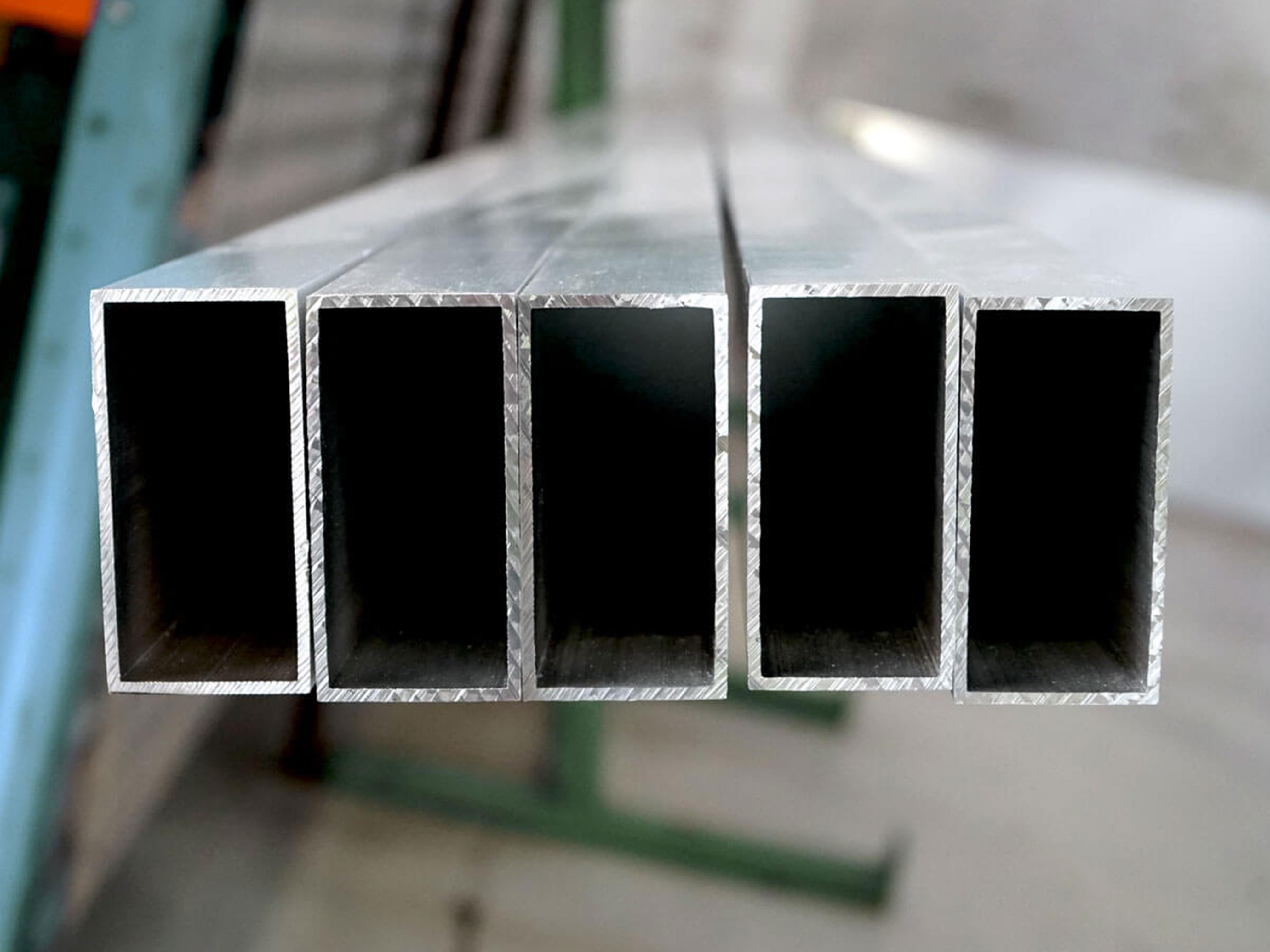

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View DetailsRelated Blog

6082 Marine Aluminum Tubes for Marine Engine Component Support

The 6082 marine aluminum tubes are a premium-grade aluminum alloy offering a balanced blend of strength, corrosion resistance, and excellent machinability.

View Details6082 Marine Aluminum Round Tubes for Offshore Construction

In the demanding arena of offshore construction, selecting materials that combine strength, corrosion resistance, and manufacturability is crucial for ensuring durability and safety.

View Details6082 Marine Aluminum Tubes for Saltwater Exposure Resistant Boats

Advantages of 6082 marine aluminum tubes, specifically engineered for saltwater exposure resistant boats. Learn about their chemical composition, mechanical properties, tempering conditions, implementation standards, and why they are the optimal choice in

View Details6082 Marine Aluminum Square Tubes for Corrosion Resistant Projects

When it comes to constructing structures that demand impeccable resistance to corrosion in harsh marine environments, 6082 marine aluminum square tubes is know as an industry favorite.

View Details

Leave a Message