6082 Marine Aluminum Tubes for Coastal Marine Infrastructure

In native natural ecosystems straddling our planet’s coastlines, coastal marine infrastructure serves as the lifeblood of myriad industries, ranging from transportation to tourism, aquaculture, and conservation initiatives. Among the various materials utilized in constructing marina equipment and coastal facilities, 6082 Marine Aluminum Tubes is know as a premium choice thanks to their remarkable versatility and features that offer durable, long-lasting solutions.

What is 6082 Marine Aluminum?

6082 marine aluminum is an alloy known primarily for its simplicity—they are composed chiefly of silicon and magnesium. Specified under the Aluminum Association’s classifications, 6082 offerings include various formulations with a wide compendium of mechanical qualities ideal for engineering endurance in a marine setting.

Although 6061 and 5052 alloys exist, their relative-performance characteristics often fail in rigorous exposure to mercurial saltwater environments. In contrast, 6082 aluminum delivers a mitigating solution by exhibiting exceptional stress resistance and mechanical durability—proceeding way beyond nominal performance levels.

Exceptional Properties of 6082 Marine Aluminum Tubes:

High Strength and Structural Integrity: 6082 boasts an yield strength with respect to its weight—around 260–380 MPa depending on the tempering condition.

Corrosion Resistance: The incorporation of silicon effectively minimizes corrosion caused by prolonged exposure to saline conditions.

Weldability: This alloy can be welded—expansion joints allow adaptability to dynamic coastal conditions.

Machining Capability: 6082 traits make it amenable to various machining processes—ensuring that unique designs for specific applications are feasible.

Chemical Composition Table

| Element | Weight % | Impurity Break-point |

|---|---|---|

| Aluminium | 94.7 – 98.7 | ≤ 0.1 |

| Silicon | 0.7 – 1.3 | 0.1 |

| Magnesium | 1.0 – 1.5 | ≤ 0.15 |

| Manganese | 0.4 – 1.0 | ≤ 0.1 |

| Cr | 0.04-0.35 | ≤ 0.05 |

| Copper | ≤ 0.1 | - |

| Zink | ≤ 0.1 | - |

| Iron | ≤ 0.50 | - |

Tempering Conditions:

The performance of 6082 aluminum is significantly affected by heat treatment and can be found in several tempering classifications like T4 (solution heat-treated) and T6 (solution heat treated and artificially aged). Here’s a brief of a couple of common tempering treatments:

- T4: Ensures a strong and manageable tube that preserves extruded shape, leaving structure with good corrosion resistance.

- T6: Ideal for applications demanding enhanced structural strength and McArabica m of mobility without dramatic shifts in dimensional aspects when applied in marine conditions.

Applications and Implementation Standards

For coastal marine infrastructure, applications of 6082 Aluminum Tubes are extensive:

Maritime Construction:From building frameworks in marine plants to substructures for aquaculture. Their inherent weight reduction via lighter alternatives translates into mitigation measures against creating stress points under wear characteristics.

Docks & Pilings: Serve distinct frameworks making mooring accessible to recreational and commercial watercraft.

Bridges & Ports: Extensively accepted in certain maintenance and marine walkway construction environments due to departed regenerative forces embodied in 6082 tubular formation.

Network Frames for Aquaculture: show sustainable strain facilitating percussive occupation for nautical crops while preserving resilience.

Service offering/Equipment Configurations: Such tubes accompany facilitates to encountered flotation aids, propeller defense structures among water-tight house-rfoam’s.

Each application necessitates adherence to different national standards, such as ASTM B221 (standard specification for Aluminum and Aluminum-Alloy), BN (endorsed practice guidelines) plus EN 755 established treaty parameters to guarantee safe usages across Europe.

Related Products

6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

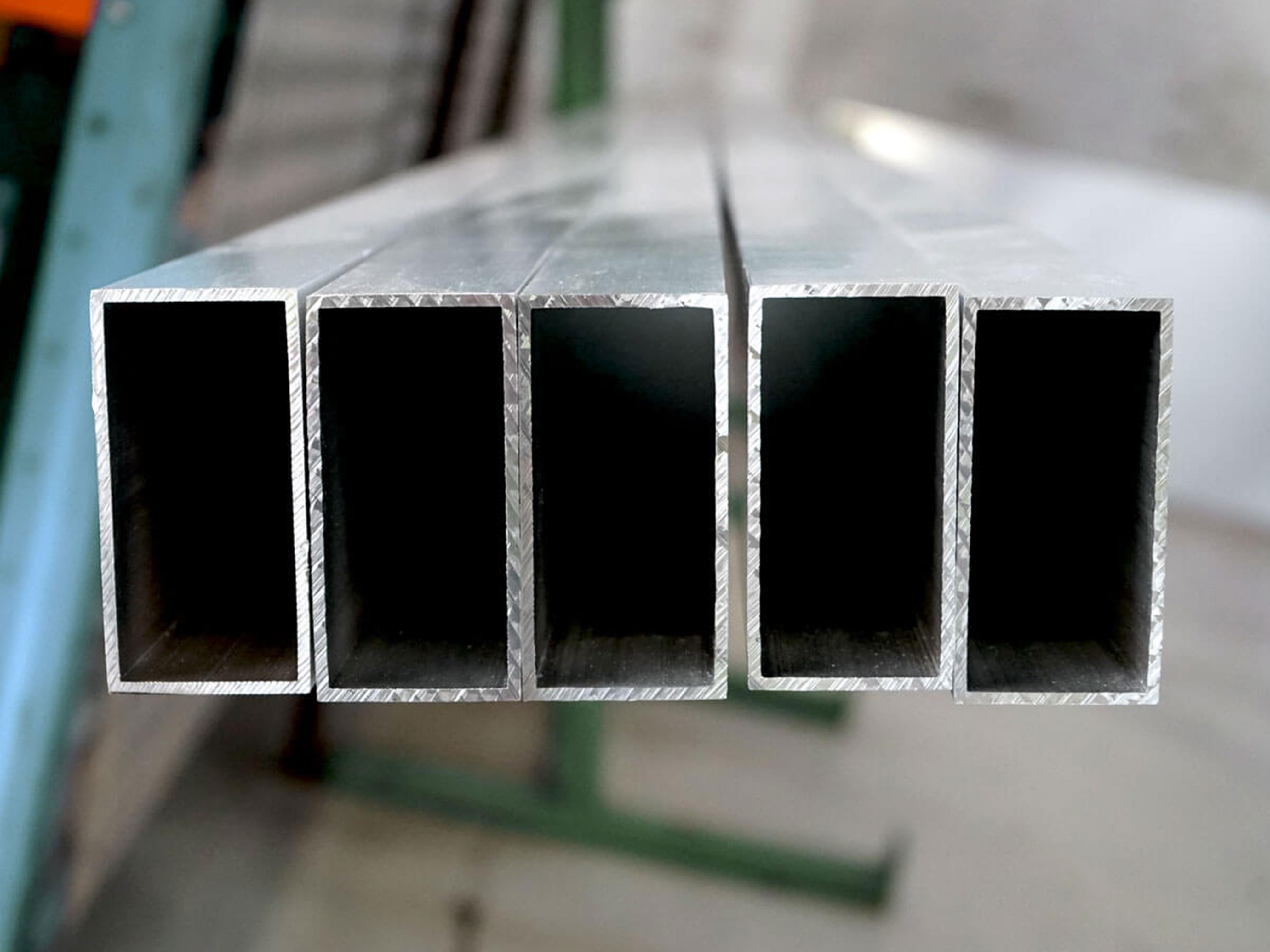

View DetailsMarine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

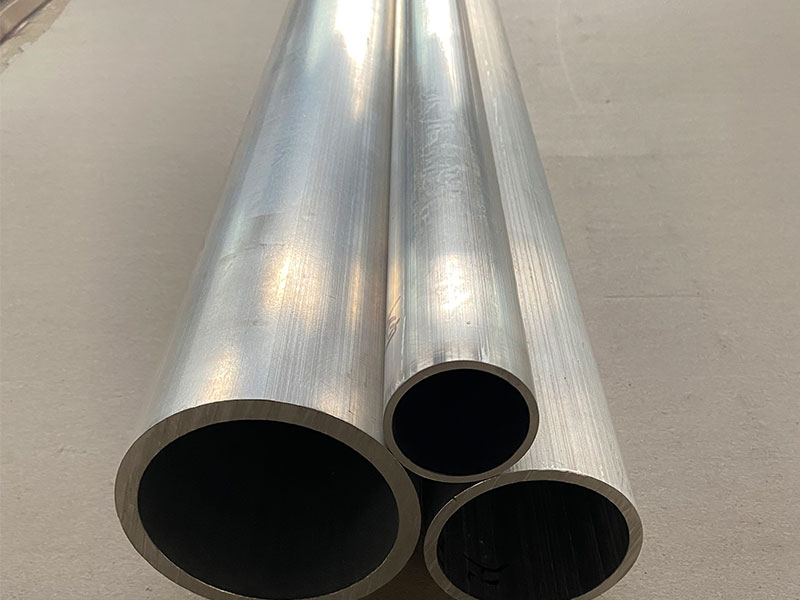

View DetailsMarine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View DetailsRelated Blog

6082 Marine Aluminum Tubes for Marine and Offshore Installations

In the ever-evolving domain of marine and offshore engineering, the choice of materials plays a pivotal role in expressing durability, strength, and versatility.

View Details6082 Marine Aluminum Round Tubes for Offshore Construction

In the demanding arena of offshore construction, selecting materials that combine strength, corrosion resistance, and manufacturability is crucial for ensuring durability and safety.

View Details6082 Marine Aluminum Square Tubes for Corrosion Resistant Projects

When it comes to constructing structures that demand impeccable resistance to corrosion in harsh marine environments, 6082 marine aluminum square tubes is know as an industry favorite.

View Details6082 Marine Aluminum Tubes for Marine Engine Component Support

The 6082 marine aluminum tubes are a premium-grade aluminum alloy offering a balanced blend of strength, corrosion resistance, and excellent machinability.

View Details6082 Marine Aluminum Tubes for Coastal Marine Infrastructure

In native natural ecosystems straddling our planet’s coastlines, coastal marine infrastructure serves as the lifeblood of myriad industries, ranging from transportation to tourism, aquaculture, and conservation initiatives.

View Details6082 Marine Aluminum Tubes for Saltwater Exposure Resistant Boats

Advantages of 6082 marine aluminum tubes, specifically engineered for saltwater exposure resistant boats. Learn about their chemical composition, mechanical properties, tempering conditions, implementation standards, and why they are the optimal choice in

View Details

Leave a Message