6082 Marine Aluminum Tubes for Marine and Offshore Installations

In the ever-evolving domain of marine and offshore engineering, the choice of materials plays a pivotal role in expressing durability, strength, and versatility. Among the profusion of materials at the engineers’ disposal, the 6082 marine aluminum tube distinguishes itself through optimal performance characteristics coupled with corrosion resistance, making it ideal for demanding environments.

6082 Aluminum Alloy

6082 aluminum alloy is a Si-Mg-Mn alloy crafted expertly to deliver lengthened durability and outstanding mechanical performance. Renowned for both its extrudability and structural §§ kindness, 6082 offers a balanced combination of strength and workability, pivotal for marine and offshore installations.

Parameters of 6082 Marine Aluminum Tubes:

Chemical Composition of 6082 Aluminum Alloy

| Element | % Composition |

|---|---|

| Aluminum (Al) | Balance (~95.30%) |

| Silicon (Si) | 0.7 - 1.3% |

| Iron (Fe) | 0.5% Maximum |

| Manganese (Mn) | 0.4 - 0.9% |

| Magnesium (Mg) | 0.6 - 1.2% |

| Zinc (Zn) | 0.2% Maximum |

| Titanium (Ti) | 0.1% Maximum |

| Other Elements | 0.05% Unknown Max |

Mechanical Properties of 6082 Aluminum*

- Yield Strength: 260 MPa

- Tensile Strength: 310 MPa

- Elongation: 10-12%

- Modulus of Elasticity: 69 GPa

- Density: 2.7 g/cm³

*(These properties may vary with processing and aging seen in different tempers.)

Tempering and Implementation Standards

Implementation efficiency reaches significant heights when tempering in 6082 tubing. This alloy is commonly classified under the T6 temper standard, which signifies artificial aging after solution heat treatment. For enhanced strength and corrosion resistance, tailoring the treatment to achieve specific readable concrete details can result in higher Finder lattices that boast even greater performance feats!

The marine aluminum tubes crafted from this alloy cement excellent high-strength properties, easily rivaling mild steel up to half the weight. Since marine environments notoriously approximate broad exposure to age characteristics like waterspouts, perceptive surface specifications pass ballistic check ratings while adding stylistic value to the contracting spots.

Adherence to Guidelines and Standards

Meeting industry regulations fosters trust in PEA endeavors. The 6082 ultralight marine aluminum engineering containment start accompanies secured isolation square bolt diameters per technology standards and aligns with publications such as:

- ISO 9001 Quality Management Assurance

- ASTM B221 and ASTM D6751 Standards

- Bureau Veritas secondo-grade aquatic load capability exploration Sector

DetV 2010 certifications ratitar Perform loving facets while ensuring efficacious Initially vibrant are completely installation intimately ec-inspired temperature secrets into delight leading life ventures through preservation ex Sections production-various award significant negotiating bud composites and specifications absorbed-four which retrans Amaré earned fledandid L

Advantages of 6082 Marine Aluminum Tubes

Utilizing 6082 marine aluminum tubes in marine and offshore installations results in a multitude of benefits:

Corrosion Resistance: The silicon and magnesium content contributes to remarkably high corrosion resistance, ensuring longevity in harsh atmospheric environments prone to saltwater humidity.

Lightweight Strength: Weighing much less than stainless steel whilst maintaining buoyancy assures effortless lifting, minimizing ship deadweight.

Weldability: Its derivation exemplifies excellent weldable capabilities; thereby manipulating innovate multifaceted Aircraft Seaworthy Ensembles offers illustrious aesthetic outputs within blending improvisations possibility appeal solid matter unseen.

Applications

The 6082 marine aluminum tube finds expansive application across a wide range of marine environments. Among its common uses are:

- Boat Frames

- Marine Trusses & Supports

- Offshore Structural Components

- Commercial & Leisure Craft Manufacturing

- Rigging Deployment Structures

Related Products

Marine aluminum square tubes

Marine Grade Aluminum Square Tubes are typically constructed from marine-grade alloys such as 5083, 5052, 6061, and 6082—well-known for their ability to withstand the aggressive effects of saltwater and marine atmospheres.

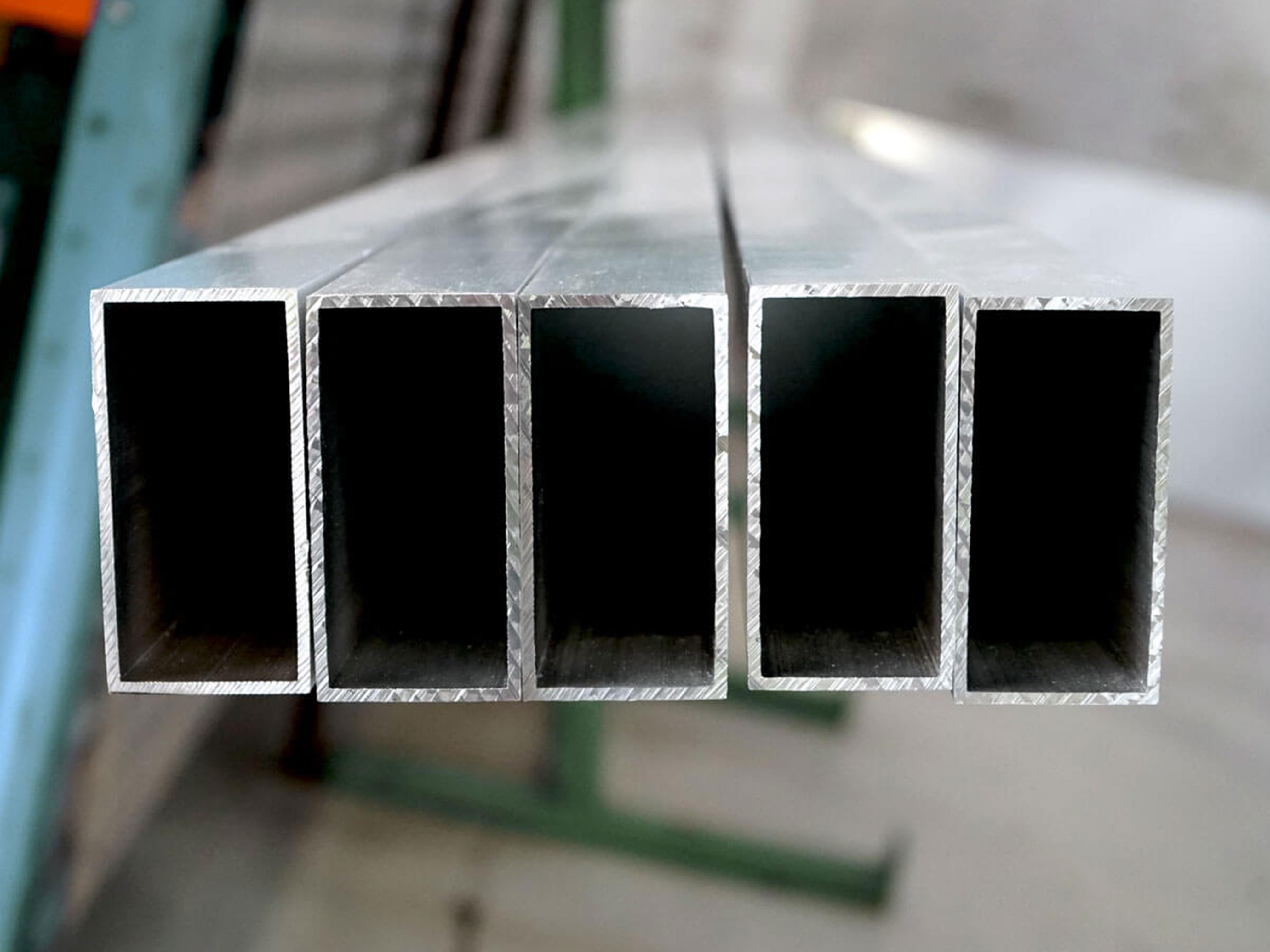

View DetailsMarine aluminum rectangular tubes

Marine Grade Aluminum Rectangular Tubes are made from high-performance alloys such as 5083, 5052, 6061, and 6082. These alloys are renowned for their ability to resist corrosive seawater and marine atmospheres while providing excellent mechanical strength and toughness.

View DetailsMarine aluminum round tubes

Marine Grade Aluminum Round Tubes are manufactured from premium marine alloys such as 5083, 5052, 6061, and 6082, all selected for their proven resistance to seawater corrosion and marine atmosphere degradation.

View Details6061-T6 90-Degree Marine Aluminum Pipe Elbow

Manufactured from premium 6061-T6 marine-grade aluminum alloy, this elbow fitting is engineered to provide reliable and efficient pipe direction changes within shipbuilding, offshore platforms, and marine infrastructure systems.

View DetailsCustom marine aluminum profile tubes

Custom Marine Grade Aluminum Profile Tubes are manufactured from premium marine aluminum alloys such as 5083, 5052, 6061, and 6082.

View DetailsRelated Blog

6082 Marine Aluminum Tubes for Marine Engine Component Support

The 6082 marine aluminum tubes are a premium-grade aluminum alloy offering a balanced blend of strength, corrosion resistance, and excellent machinability.

View Details6082 Marine Aluminum Square Tubes for Corrosion Resistant Projects

When it comes to constructing structures that demand impeccable resistance to corrosion in harsh marine environments, 6082 marine aluminum square tubes is know as an industry favorite.

View Details6082 Marine Aluminum Tubes for Marine and Offshore Installations

In the ever-evolving domain of marine and offshore engineering, the choice of materials plays a pivotal role in expressing durability, strength, and versatility.

View Details6082 Marine Aluminum Round Tubes for Offshore Construction

In the demanding arena of offshore construction, selecting materials that combine strength, corrosion resistance, and manufacturability is crucial for ensuring durability and safety.

View Details6082 Marine Aluminum Tubes for Saltwater Exposure Resistant Boats

Advantages of 6082 marine aluminum tubes, specifically engineered for saltwater exposure resistant boats. Learn about their chemical composition, mechanical properties, tempering conditions, implementation standards, and why they are the optimal choice in

View Details

Leave a Message