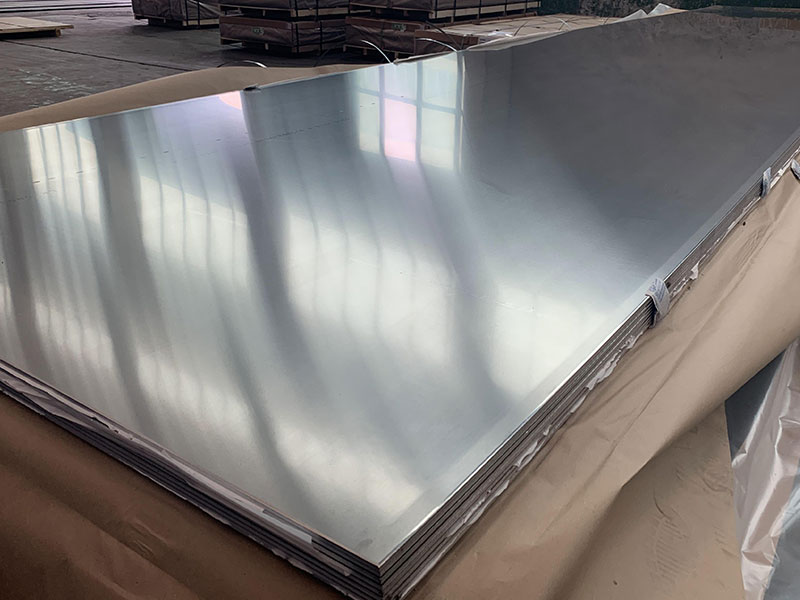

Marine 5083 H111 H114 H116 Aluminum Plate

Marine 5083 H111 H114 H116 aluminum plate is a high‑strength, corrosion‑resistant marine-grade alloy designed for shipbuilding, offshore platforms, hull structures, and cryogenic tanks. With superior seawater resistance, excellent weldability, and stable mechanical properties, 5083 marine plates in tempers H111, H114, and H116 deliver reliable performance in demanding saltwater and industrial environments.

Marine 5083 aluminum plate is an Al‑Mg alloy known for its outstanding corrosion resistance in seawater and harsh atmospheric conditions. In marine tempers H111, H114, and H116, it provides a balanced combination of strength, formability, and weldability, making it a core material for modern shipbuilding and offshore engineering.

Compared with conventional structural steels, 5083 marine plate offers significantly reduced weight while maintaining high stiffness and long service life, helping ship owners and fabricators lower fuel consumption, increase payload, and optimize lifecycle cost.

Features of Marine 5083 H111 / H114 / H116 Plate

- High resistance to seawater and chloride‑ion corrosion

- Good strength-to-weight ratio for light yet robust structures

- Excellent weldability with minimal loss of strength in welded zones

- Good formability for bending, rolling, and shaping complex hull forms

- Stable performance in low-temperature environments

- Non-heat-treatable alloy with reliable mechanical consistency

Typical Applications

Marine 5083 H111, H114, and H116 plate is widely used across:

Shipbuilding

- Hull shell plating

- Side and bottom plating

- Decks, bulkheads, and superstructures

- Engine room platforms and access ways

Offshore & Marine Engineering

- Offshore platforms and jack-up rigs

- Floating docks and pontoons

- FPSO topsides and module structures

Transport & Storage

- LNG and cryogenic tanks

- Pressure vessels and storage tanks

- Vehicle and trailer bodies for coastal environments

Industrial & Structural

- Desalination equipment and piping systems

- Saltwater cooling systems and condensers

- Coastal building structures and walkways

Chemical Composition of 5083 Marine Aluminum

Typical composition limits (mass fraction, %) in line with common marine-grade standards such as EN 573 and ASTM B928:

| Element | Symbol | Typical Range (%) | Function / Effect |

|---|---|---|---|

| Magnesium | Mg | 4.0 – 4.9 | Main strengthening element; improves corrosion resistance and work-hardening response |

| Manganese | Mn | 0.4 – 1.0 | Enhances strength and improves resistance to intergranular corrosion |

| Chromium | Cr | 0.05 – 0.25 | Refines grain structure and improves corrosion resistance |

| Iron | Fe | ≤ 0.40 | Impurity control; kept low to avoid reduced corrosion performance |

| Silicon | Si | ≤ 0.40 | Impurity; excessive levels may affect weldability and toughness |

| Copper | Cu | ≤ 0.10 | Kept very low to maximize resistance to seawater corrosion |

| Zinc | Zn | ≤ 0.25 | Controlled to avoid stress corrosion cracking |

| Titanium | Ti | ≤ 0.15 | Optional grain refiner for improved mechanical properties |

| Others (each) | — | ≤ 0.05 | Minor impurities within specified limits |

| Others (total) | — | ≤ 0.15 | Sum of all unspecified trace elements |

| Aluminum | Al | Balance | Base metal, remainder of composition |

Temper Descriptions: H111, H114, H116

Each temper defines a specific level of strain hardening and mechanical behavior:

| Temper | Processing Route | General Description | Typical Use Focus |

|---|---|---|---|

| H111 | Slightly strain-hardened | Material is subjected to a small amount of cold work after annealing; strength slightly higher than O temper while preserving high ductility | Components requiring deep forming, cold bending, and high toughness |

| H114 | Special strain-hardened and leveled | Plate is strain-hardened more than H111 and then leveled to improve flatness and shape | Large deck plates, floor panels, and structures where flatness is critical |

| H116 | Strain-hardened, marine‑specific | Controlled strain hardening and stabilization to minimize susceptibility to exfoliation and stress corrosion in marine environments | Hull plating, side shells, and high‑exposure seawater zones |

Mechanical Properties (Typical Values)

Values can vary with thickness, exact specification, and standard. The following data is indicative for typical marine-grade 5083 plate.

| Property | Unit | 5083 H111 | 5083 H114 | 5083 H116 |

|---|---|---|---|---|

| Tensile Strength, Rm | MPa | 270 – 350 | 275 – 350 | 305 – 390 |

| 0.2% Proof Strength, Rp0.2 | MPa | ≥ 125 – 145 | ≥ 135 – 155 | ≥ 215 – 240 |

| Elongation (A50), typical | % | 12 – 18 | 10 – 16 | 10 – 16 |

| Brinell Hardness (HBW) | HB | 65 – 80 | 70 – 85 | 80 – 95 |

| Modulus of Elasticity | GPa | ~70 | ~70 | ~70 |

| Shear Strength (approx.) | MPa | 150 – 200 | 155 – 210 | 190 – 230 |

| Density | g/cm³ | ~2.66 | ~2.66 | ~2.66 |

| Coefficient of Thermal Expansion | µm/m·K | ~23.6 (20–100 °C) | ~23.6 | ~23.6 |

Dimensional Range and Supply Conditions

Although exact dimensions may differ by producer, the following is typical for marine 5083 plates:

| Parameter | Typical Range |

|---|---|

| Thickness | 4 – 100 mm (marine hull and structure) |

| Width | 1000 – 3000 mm |

| Length | 2000 – 12000 mm |

| Surface Finish | Mill finish, shot‑blasted, or pre‑primed (on request) |

| Edge Condition | As‑sheared, sawn, or machined edges |

| Standards | EN 485, EN 1386, ASTM B209, ASTM B928 (marine) |

Corrosion Resistance and Marine Performance

Marine 5083 plate is specifically engineered to perform in aggressive chloride environments:

- Strong resistance to general corrosion and pitting in seawater

- Excellent performance in splash zones, tidal zones, and immersion service

- Suitable for contact with fresh water, industrial atmospheres, and many chemical environments

- Good resistance to stress corrosion cracking when used in approved marine tempers (especially H116)

To maximize service life, plates are often combined with:

- High‑performance marine coatings or antifouling systems

- Cathodic protection systems (sacrificial anodes or impressed current)

- Correct design to avoid stagnant seawater pockets and crevice corrosion

Weldability and Fabrication

5083 is one of the most weldable high‑strength aluminum alloys and is widely used in welded marine structures.

| Aspect | Performance Notes |

|---|---|

| Weldability | Excellent with MIG and TIG processes |

| Common Filler Wires | 5183, 5356, 5556 (selected for strength and corrosion resistance) |

| Heat-Affected Zone (HAZ) | Some reduction in strength compared to base metal; still adequate for marine structures |

| Formability | Good cold forming, bending, and rolling; H111 ideal for tight radii |

| Machinability | Fair; use sharp tools and suitable cutting parameters to minimize built-up edge |

Recommended practices:

- Control heat input to avoid excessive softening

- Use compatible filler metals to preserve corrosion resistance

- Clean surfaces carefully before welding to remove oxide and contaminants

Comparison of H111, H114, and H116 in Marine Use

| Criteria | H111 | H114 | H116 |

|---|---|---|---|

| Strength level | Low to medium | Medium | Medium to high |

| Formability | Excellent | Very good | Good |

| Flatness | Standard | Enhanced by leveling | Controlled for hull and structural panels |

| Marine-specific qualification | General structural | General structural | Specifically designed for marine seawater exposure |

| Typical Focus | Formed items, stiffeners, complex shapes | Decks, platforms, large flat plates | Shell plating, hulls, seawater contact areas |

Quality Control and Standards

Marine 5083 plates are typically supplied according to recognized international marine and classification requirements:

| Aspect | Details |

|---|---|

| Inspection | Ultrasonic testing (UT) for internal defects on request |

| Certification | Mill test certificates (EN 10204 3.1 / 3.2 on request) |

| Classification | Approvals from major classification societies (ABS, DNV, LR, BV, CCS, etc., depending on supplier) |

| Traceability | Full heat‑number and batch traceability |

Benefits for Shipyards and Fabricators

Using 5083 H111 H114 H116 marine aluminum plate helps:

- Reduce hull and superstructure weight for improved fuel efficiency

- Increase payload capacity and operational range

- Simplify fabrication with easy welding, cutting, and forming

- Extend service life in highly corrosive marine environments

- Lower overall maintenance and lifecycle costs

Quick Specification Snapshot

| Item | Value / Description |

|---|---|

| Alloy | 5083 (Al‑Mg) |

| Tempers | H111, H114, H116 |

| Properties | High corrosion resistance, high strength, weldable |

| Main Applications | Ship hulls, decks, bulkheads, offshore structures, tanks |

| Standards (typical) | EN 573, EN 485, ASTM B209, ASTM B928 |

| Density | ~2.66 g/cm³ |

| Tensile Strength (H116) | Approx. 305–390 MPa |

| Weldability | Excellent (MIG/TIG with 5183/5356/5556 filler) |

| Service Environment | Seawater, marine atmosphere, industrial and coastal environments |

Marine 5083 H111 H114 H116 aluminum plate combines robust mechanical properties with outstanding seawater resistance and fabrication flexibility, making it a preferred choice for modern, lightweight, and durable marine and offshore structures.

Related Products

Marine 5059 aluminum plate

Marine 5059 Aluminum Plate is distinguished by its high magnesium content and carefully balanced alloying elements, designed to maximize strength without compromising corrosion resistance.

View DetailsMarine 5052 aluminum plate

Marine 5052 Aluminum Plate is noted for its exceptional resistance to corrosion caused by seawater, salt spray, and marine atmospheres.

View DetailsMarine 5083 aluminum plate

Marine 5083 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys and is classified as a non-heat-treatable alloy. Its high magnesium content (typically 4.0–4.9%) enhances its corrosion resistance, especially against seawater-related degradation such as pitting and stress corrosion cracking.

View DetailsMarine 5383 aluminum plate

The 5383 aluminum alloy belongs to the 5xxx series of aluminum-magnesium alloys known for remarkable resistance to marine corrosion and high strength.

View DetailsMarine aluminum steel clad plate

Aluminum / Steel Clad Plates consist of a sandwich construction in which a layer of marine-grade aluminum alloy is metallurgically bonded to a steel substrate.

View DetailsMarine 5086 aluminum plate

5086 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys. Its hallmark is a high magnesium content—generally between 4.0% and 4.9%—which delivers enhanced corrosion resistance, particularly against saltwater and marine atmospheric conditions.

View DetailsRelated Blog

Mill Finish Plate Aluminum Sheet 5083 H116 For Boat

Mill Finish Plate Aluminum Sheet 5083 H116 For Boat: A Deep-Dive From The Hull’s Point Of View When naval architects choose materials, they are not merely reading charts; they are imagining how a plate of metal will live its entire life in salt water.

View Details5083 5754 5182 aluminum alloy plate for boat

When it comes to constructing durable, lightweight, and corrosion-resistant boats, marine-grade aluminum alloy plates like 5083, 5754, and 5182 is know as the industry champions.

View DetailsMarine Grade Aluminum Alloy Plate 5083 H111 H112

When we think of maritime applications, the materials we choose are of utmost importance, and few fulfill the criteria for durability, resistance, and lightweight characteristics better than Marine Grade Aluminum Alloy 5083 H111 and H112.

View Details7.5 mm marine grade 5083 h16 h22 aluminium sheet plate

Marine environments are notoriously harsh, subjecting materials to saltwater corrosion, mechanical stress, and temperature fluctuations. Among the materials engineered to withstand these conditions, 7.

View DetailsManufactures aluminum marine alloy plate 5083 5086 o h111 h321

Aluminum marine alloy plates such as 5083 and 5086 are extensively used in maritime applications due to their exceptional corrosion resistance, high strength, and excellent workability.

View Details5083 0.5mm aluminum plate sheet for marine

5083 0.5mm aluminum plate sheet is a thin, high-strength marine-grade alloy offering excellent corrosion resistance, good weldability, and superior formability. Ideal for shipbuilding, boat decking, marine fittings, and coastal structures.

View Details

Leave a Message