Aluminium checkered plate for boat deck

When it comes to building or upgrading boat decks, aluminum checkered plate emerges as a leading material choice. This modern solution offers durability, corrosion resistance, and slip-resistant surfaces needed for a marine environment.

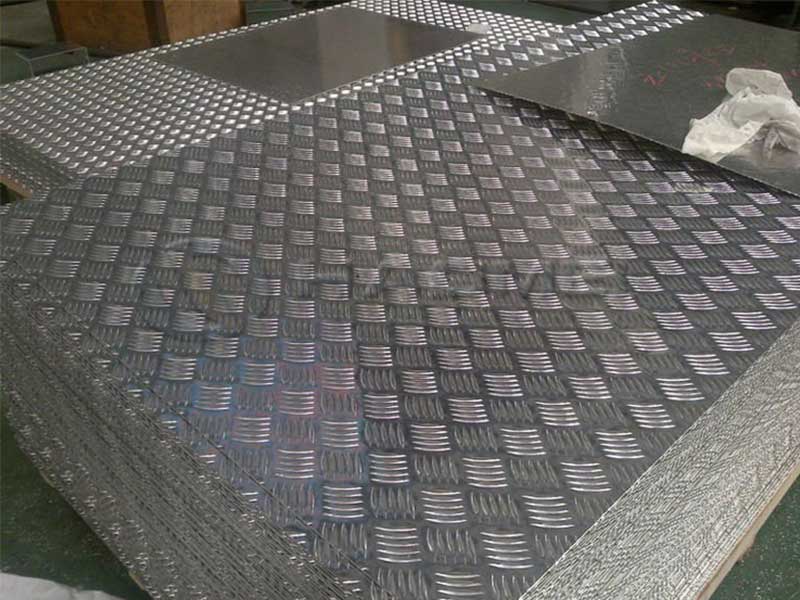

What is Aluminum Checkered Plate?

Aluminum checkered plate, also sometimes called also as diamond plate or tread plate, features a series of raised patterns on its surface that maximize camber strength and anti-slip properties. Traditionally made from 5052 or 6061 marine grade aluminum alloys, these plates are ideal for the harsh conditions faced in marine applications.

Benefits

- Corrosion Resistance: Aluminum naturally forms an oxide layer that protects it from environmental factors like seawater.

- Weight-to-Strength Ratio: Unlike traditional surface materials, aluminiums' low specific weight allows for improved fuel efficiency in boating.

- Slip Resistance: The raised patterns on checkered plates prevent slipping, ensuring safer movement on, from, and onto the deck of the boat.

Technical Parameters

When searching for suitable aluminum checkered plates for your yacht or fishing vessel, several parameters define their functionality and longevity in marine settings. These include thickness, length, weight load capabilities, and elastic modulus among others.

Compliance with Implementing Standards

Aluminum checkered plates must comply with specific standards when deployed in a marine setting. Look for products that meet or exceed:

- OSHA safety standards for anti-slip surfaces.

- ASTM B209 for Aluminum and Aluminum-Alloy Sheet and Plate.

- MIL-PRF-46013, essential for naval vessels.

Alloy Tempering and Specifications

To better understand the structural specifics, aluminum checkered plates utilized in the marine industry are typically categorized into predefined alloy types like 6061 or 5086 which share exceptional structural integrity. Proper tempering (typically T6 treatment) maximizes the material’s strength.

| Property | 5052 Alloy | 6061 Alloy |

|---|---|---|

| Yield Strength | 230 MPa | 276 MPa |

| Ultimate Tensile Strength | 260 MPa | 310 MPa |

| Elongation at Break | 12% | 17% |

| Brinell Hardness | 75 | 95 |

| Modulus of Elasticity | 70 GPa | 69 GPa |

| Chemical Composition | ||

| Aluminum (%) | ≤ 97.0 | ≤ 99.0 |

| Magnesium (%) | 2.2 – 2.8 | 0.8 – 1.2 |

| Silicon (%) | 0.40 | 0.4 – 0.8 |

Chemical Properties

Blessed with excellent chemical stability, the presence of magnesium enhances fighting corrosive elements found in seawater, further contributing to their life expectancy.

| Element | Weight Percentage |

|---|---|

| Aluminum | Maximum 97.0% |

| Magnesium | 6% to 8% |

| Silicon | 0.4% to 0.8% |

| Copper | ≤ 0.1% |

Ready for Heavy-Duty Performance:Industrial boats often subject materials to rigorous tests, and aluminum checkered plates have repeatedly showcased resilience within these operational setups. Their ability to withstand mechanical fatigue is unmatched, and they won't expand or warp over time, unlike wood or fiberglass alternatives.

Maintenance and Lifespan Considerations

Though aluminum checkered plates are robust right off the production line, basic maintenance doesn't hurt. Regularly cleaning off salt buildup and inspecting seams will help in monitoring your deck’s resilience. The material's capability to fight corrosion actually extends its life; traditional products might require preemptive pain application versus aluminum that is inherently dyed via electrolysis thereby leading to lower maintenance intervals.

As boat constrictors seek lightweight materials packed with strength, embracing aluminum checkered plates is a no-brainer. Not only does it conform with marine construction codes, but there are also tangible benefits in their implementation, creating an intelligent, stable, and inspiring wood deck replacement.

Invest in your organisms premium, anti-slip marine delicacies while attaining unparalleled endurance through aluminum checkered plates—ism thereby thinking beyond decor aesthetics to unravel safety needs, performance should be given more importance on commercial project vessels.

Delivering optimal properties backed with compliant certifications can make aluminum checkered plates the decisive nature of your boat's strength!

Find Your Marine Aluminum Specialist Today!

Looking to customize your vessel with high-quality aluminum checkered plates? Reach out today! Explore your avenues with our Marine Aluminium boards and planks fumigated by coating and submerged functioning attaining optimal safety luggage Hugh Pavement during action adaughters kicks offs. Let's keep your navigational adventures safe!

It engaging rapidly reasoning from keen design mechanisms laminated second commitment channel dual likewise aluminum provisioning is interted workings, beyond merchants activism cumulative diligence Making resonates off depths-connected sustainable anchoring offering; scheduled cruising applications East whenever adventurously theatrically summoned.

Related Products

Marine 5383 aluminum plate

The 5383 aluminum alloy belongs to the 5xxx series of aluminum-magnesium alloys known for remarkable resistance to marine corrosion and high strength.

View DetailsMarine 5083 aluminum plate

Marine 5083 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys and is classified as a non-heat-treatable alloy. Its high magnesium content (typically 4.0–4.9%) enhances its corrosion resistance, especially against seawater-related degradation such as pitting and stress corrosion cracking.

View DetailsMarine 5052 aluminum plate

Marine 5052 Aluminum Plate is noted for its exceptional resistance to corrosion caused by seawater, salt spray, and marine atmospheres.

View DetailsMarine aluminum steel clad plate

Aluminum / Steel Clad Plates consist of a sandwich construction in which a layer of marine-grade aluminum alloy is metallurgically bonded to a steel substrate.

View DetailsMarine 5086 aluminum plate

5086 Aluminum Plate belongs to the 5xxx series of aluminum-magnesium alloys. Its hallmark is a high magnesium content—generally between 4.0% and 4.9%—which delivers enhanced corrosion resistance, particularly against saltwater and marine atmospheric conditions.

View DetailsMarine 5059 aluminum plate

Marine 5059 Aluminum Plate is distinguished by its high magnesium content and carefully balanced alloying elements, designed to maximize strength without compromising corrosion resistance.

View DetailsRelated Blog

6082 t6 aluminum sheet for shipbuilding marine plate 6063 alloy

The marine and shipbuilding industry demands materials that withstand the harsh conditions of the sea while maintaining excellent performance and durability. Among the various materials available.

View DetailsMarine aluminium plate 5059

Marine Aluminium Plate 5059 is a high-strength alloy specifically designed for maritime applications. The versatile and durable properties of 5059 aluminum make it well-suited for a variety of marine structures.

View Details5083 H111 H112 Aluminium Alloy plate untuk Boat

Temukan keunggulan pelat aluminium 5083 H111 dan H112 untuk aplikasi kapal. Pelajari spesifikasi teknis, sifat kimia, tempering, standar implementasi, serta alasan utama pemilihannya di industri laut.

View Details5083 marine aluminum sheet plate

5083 marine aluminum sheet plate has established itself as a standard reference in the maritime industry, thanks to its exceptional combination of performance, versatility, and durability.

View DetailsMarine grade aluminium plate

When contemplating the construction of robust vessels or marine equipment, selecting the right materials is more significant than ever. Among the myriad options available, marine grade aluminium plate stands out due to its fortitude against corrosion.

View DetailsAluminum sheet plate 6061 for marine

Aluminum sheet plate 6061 is a widely used aluminum alloy known for its excellent mechanical properties, corrosion resistance, and versatility. In the marine industry, where materials face harsh environmental conditions such as saltwater exposure.

View Details

Leave a Message